ODiSI 6

ODiSI 6

User’s Guide

Page 74

7

ODiSI Remote Operation

ODiSI Remote Application

The ODiSI Remote application provides the ability to Arm, Start, Stop, and Disarm the ODiSI

controller software from a remote PC. When the ODiSI controller software is making

measurements, the remote software will display the measurement data in real time. The ODiSI

instrument and controller must be running in order for the ODiSI Remote application to

connect successfully to the ODiSI controller.

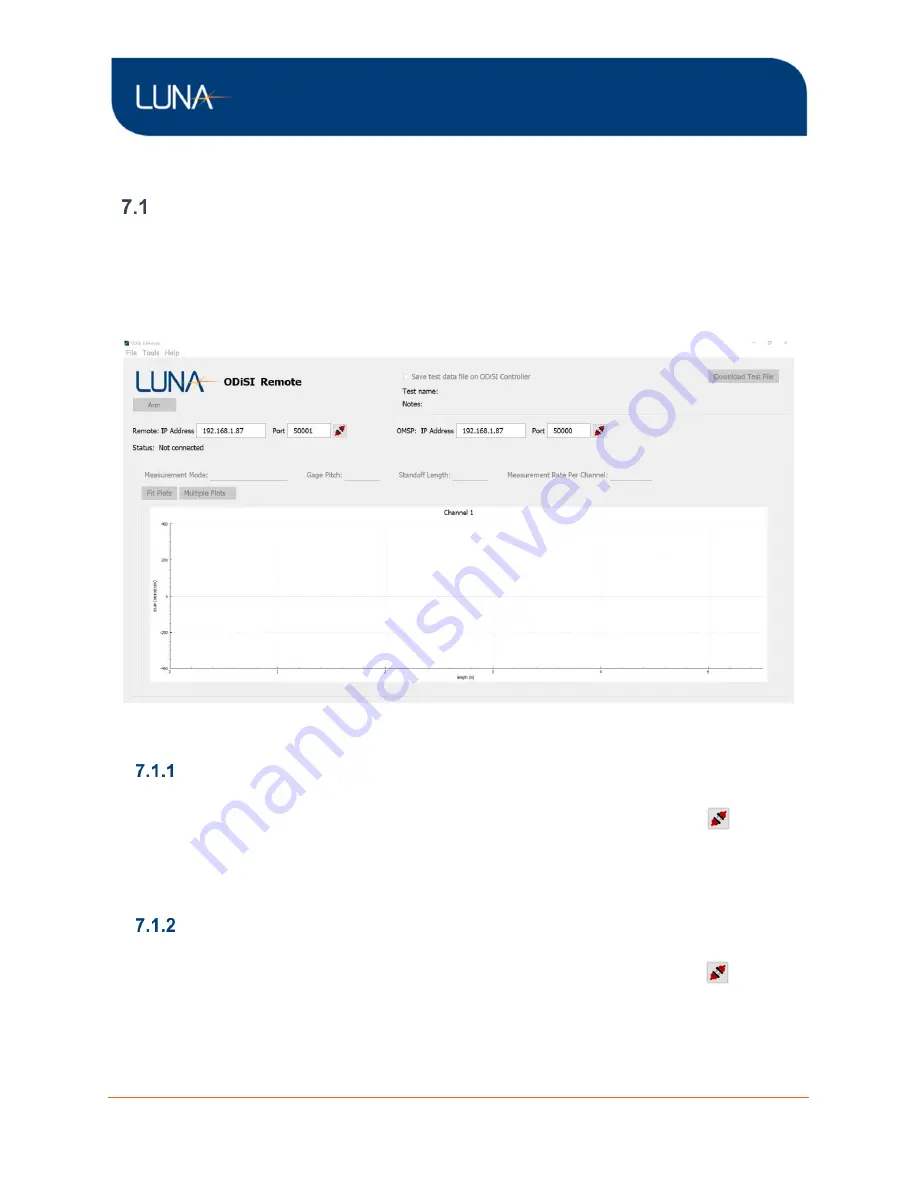

Figure 7-1: ODiSI Remote application window

Remotely Control an ODiSI

Configure the Remote Software with the same IP address and port displayed in the main

ODiSI

control software’s Streaming Properties tab. Click the plug head button

, which will

change from red to green upon successful connection.

The ODiSI Remote application provides limited remote control functionality. The user can

Arm/Disarm, Start/Stop, and enable/disable test data file logging on the ODiSI controller.

Stream in ODiSI Measurement Data

Configure the Remote Software with the same IP address and port displayed in the ODiSI

main control software’s Streaming Properties tab. Click the plug head button

, which will

change from red to green upon successful connection.

Measurement data as defined by Gages and Segments will be streamed into the ODiSI

Remote application and can be displayed on a Sensor Plot. Within the Sensor Plot, Gages

will be displayed as circle markers while Segments will be displayed as a line plot.