P A D - C L I M A T E - S Y S T E M

Assembly instruction and operators manual

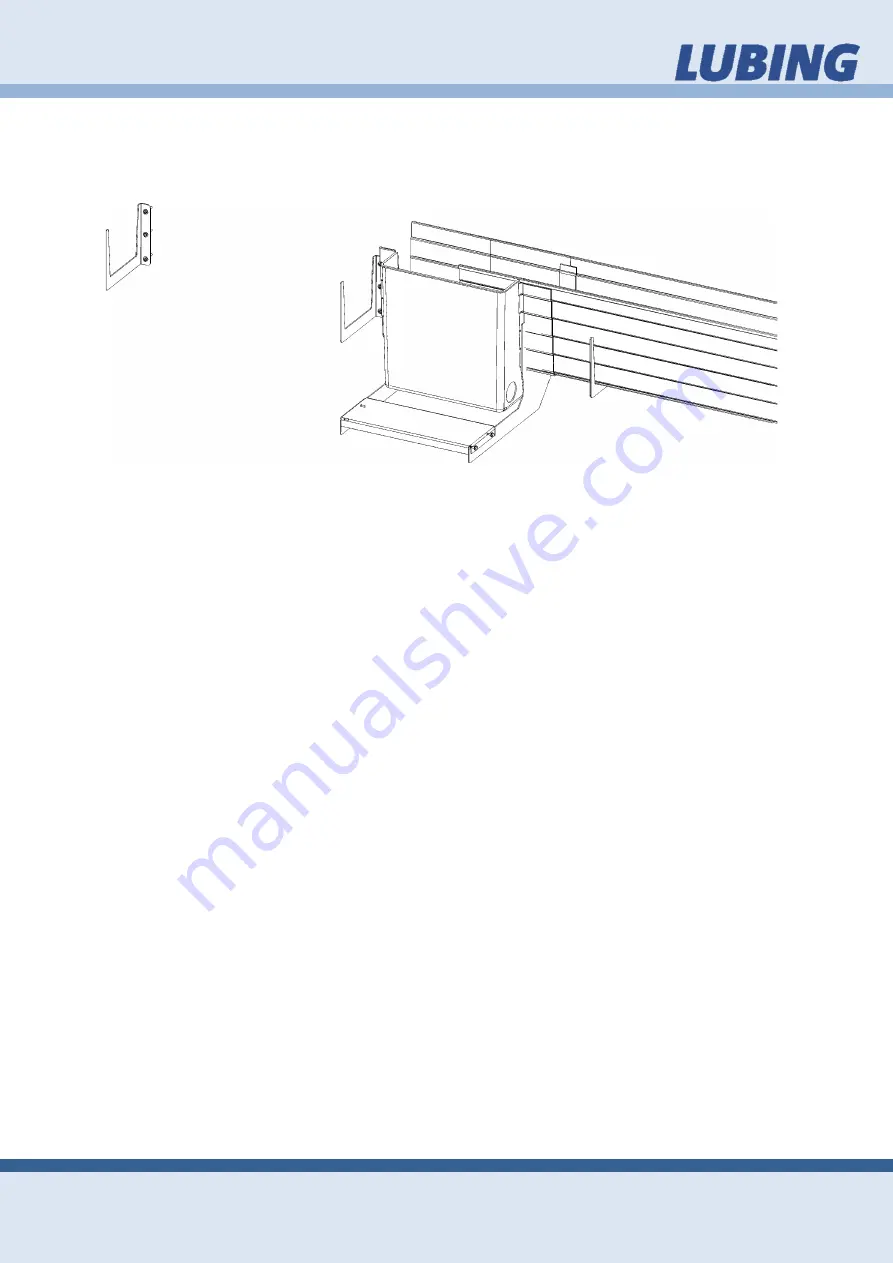

Assembly

12

3.7.2. Watergutter

Beginn the glueing of the Watergutter and the Coupler for Watergutter with the hous-

ing of the Supply Unit up to the End Cover.

Consider the following points for a waterproof connection:

•

sufficient adhesive quantity in the coupler particularly in the corners and at the

front of the Watergutter (Addehsive should get out from the coupler)

•

Brisk processing (see 3.7.3 Glued connections)

•

Accurate seat of the coupler and the Watergutter to each other (push Wa-

tergutter up to the stop into the coupler).

•

During drying (24 hours) do not move the entire system any longer.

3.7.3. Glued connections

LUBING recommends "Tangit" adhesive for glued connections.

Many connection elements in the LUBING product range are designed as glued con-

nections. Please observe the following manufacturer instructions in order to ensure

secure connections.

The pipe must be cut at a right angle and burred. The areas to be glued must be

clean and dry. Clean the ends of the pipe on the outside and the connecting ele-

ments on the inside using a cleaning agent (please check compatibility) and woven

felt. Always use new woven felt. The areas to be glued must be fully dry before ap-

plying the adhesive.

Push the pipe and connecting element without twisting until the limit stop and hold

tight for a few seconds until the glue has set. Immediately following joining, remove

superfluous glue with the woven felt as otherwise the pipe will be etched too strongly.

Owing to the fast setting features of the adhesive, the join parts must be pushed to-

gether within 4 minutes of applying the glue. The open period for Tangit depends on

the ambient temperature and/or film thickness.