17

E

NG

LISH

Assembling instrunctions and maintenance

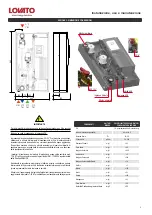

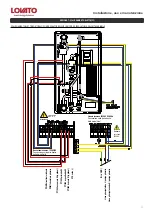

T-FAST ie40 is an instantaneous domestic hot water production module that uses the working principle of a stainless steel plates exchanger.

The setting of the domestic hot water outlet temperature (secondary side) happens with the modulation of the primary circuit flow rate through a variable flow pump controlled by

MFWC controller (PWM control).

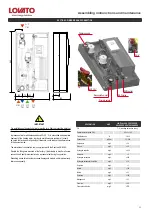

- No.1 module T-FAST ie40

- No.1 assembling instructions

- No.1 circulation pump assembling instructions

- No.2 immersion sensors

SECTION 1: INTRODUCTION AND GENERAL INSTRUCTIONS

DESCRIPTION

PACKING LIST

!

!

Consult this manual carefully before proceeding with any intervention on the equipment.

The manufacturer, in order to adapt to technological and equipment needs of the productive character or installation, may, without notice, make modifications to it.

Therefore, although the illustrations in this manual can differ slightly from the equipment in your possession, safety is the same guaranteed.

This manual is part of the product and should be adequately stored so that it could be consulted during the lifetime of the equipment.

Keep the instructions with the product if you are transfering to another owner.

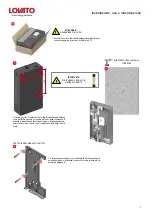

Preliminary checks

Before each operation carefully remove the packaging and check the integrity of the equipment. If you note some defects or damages do not install it or attempt to repair the equip

-

ment, but contact your dealer.

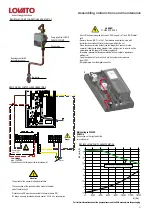

Installation

All operations on the product must be made with power disconnected from the mains.

Installation should be done in accordance with the laws and regulations of each country.

Producer responsibility is limited to providing the equipment. Its installation should be made in conformity with the rules of art, according to the requirements of these instructions

and the rules of their profession by qualified staff, acting under suitable companies to take full responsibility of the whole plant.

LOVATO S.p.A. is not responsible for the product modified without permission, and for the replamcements of no-original components.

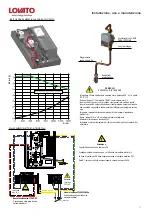

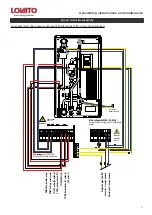

Electrical connection

The controller must be installed and connected by authorized staff according to applicable regulations.

Connect the power supply to the control unit complete with bipolar switch fuses (power 230Vac 50Hz). It is essential to connect the proper grounding

Please follow theese tips:

• Do not touch hot parts of the module such as pipe inlet and outlet of water. Every contact

with them can cause dangerous burning.

• Do not expose the unit to spray water and other liquids.

• Do not place anything on the unit.

• Do not expose the unit to vapors from a cooking surface.

• Prohibit the use of the equipment for children and inexperienced people.

• Do not touch the appliance with wet or damp parts of the body and / or bare feet.

• Do not pull the wires.

Installation, connections and testing must be done by qualified staff who works in accordance with the standards and follows the instruction manual.

All piping should be insulated in accordance with the law.

The controller must be connected into the network as the current regulations demands. The proper functioning of the controller is guaranteed only for the

provided pump.

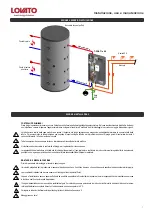

Hydraulic connections

After delivery of the product, ensure the tightening of all nuts fixing the pipes.

Be especially careful when you are connecting the piping kit to the hydraulic module, and avoid to bend the copper pipes.

GENERAL INSTRUCTIONS AND SAFETY RULES

Содержание 49060463

Страница 15: ...15 Installazione uso e manutenzione...

Страница 29: ...29 Assembling instrunctions and maintenance...

Страница 43: ...43 Instructions relatives l installation l utilisation et la maintenance...

Страница 57: ...57 Montage und Wartungsanleitung...