Owners Manual

s

Rexnord

®

Planetgear™ 7000 Series Speed Reducers

(Page 22 of 32) Sizes Neptune, Neptune Plus, Orion Plus, Saturn Plus & Titan Plus

158-170

Rexnord

January 2015

3001 W. Canal St., Milwaukee, WI 53208-4200 USA

Supersedes 11-12

Telephone:414-342-3131 Fax: 414-937-4359 www.rexnord.com

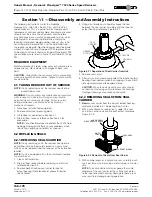

11. With an arbor press or a hydraulic press carefully push

bearing cone. When bearings begin to approach the

bearing cup, apply clean oil to outboard bearings.

NOTE

: DO NOT push on bearing rollers or bearing

cage; reference Figure 6.3.6.2.

12. Press outboard bearing until it touches the surface of

the bearing cup.

NOTE

: Do not over push bearings into cup. This might

cause the bearings to Brinell the cup.

NOTE

: An indication when the outboard bearing is

fully seated is when the hub will not rotate on the shaft

freely.

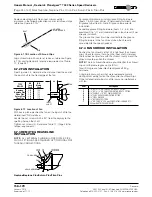

13. Clean and place the tongued washer onto the shaft.

14. Clean clampnut. Place it with the grooved side down

(or groove towards bearings) and thread on clampnut

until it is unable to rotate.

15. Mark the location of the clampnut.

16. Loosen clampnut approximately

¾

” (19 mm) from

original mark.

17. Tighten socket head cap screw on clampnut; reference

Table 14, Page 23.

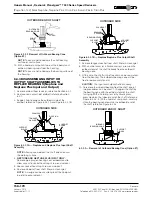

18. Support hub and affix to work table with the shaft not

touching the table; reference Figure 6.4.1, next page.

19. With an arbor press or a hydraulic press, push on the

inboard end of the shaft to relieve the bearings.

NOTE

: A popping noise will sound when bearings are

relieved. If the noise does not occur , an alternative

way to determine if the bearings have been relieved is

if the housing rotates freely on the bearings.

20. Reference Axial Bearing Clearance, Section 6.4 for

proper bearing endplay.

21.

NEPTUNE AND NEPTUNE PLUS INPUT ONLY

—

After setting the axial bearing clearance, replace pipe

plug on housing near outboard end sealing it in the

process with thread sealant.

6.4 SETTING PROPER AXIAL BEARING

CLEARANCES ON INPUT OR OUTPUT

SHAFT ASSEMBLIES

6.4.1 MEASURING AXIAL CLEARANCE ON

INPUT AND OUTPUT ASSEMBLIES

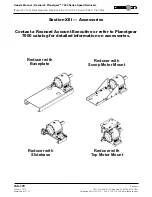

1. Support housing to allow the shaft to rotate freely;

reference Figure 6.4.1.

NOTE

: If necessary, the axial bearing clearance can be

measured by orientating the larger assemblies outboard

side down. The dial indicator should then be placed on

the inboard end of the shaft while prying upwards on

the outboard end of the shaft.

NOTE

: Axial clearance should be checked while seal

carrier is removed.

2. Affix the hub to the support table with C-Clamps or

bolting to table; reference Figure 6.4.1.

3. While exerting downward force by hand on the end of

the shaft, rotate shaft 6 to 10 times to align the bearing

rollers.

4. Use a dial indicator with a magnetic base to take

measurements.

NOTE

: Use a dial indicator that has a balanced dial with

0.0001” or 0.010 mm graduations.

5. Affix the magnetic base of the dial indicator to a flat

area of the housing; reference Figure 6.4.1.

6. Place the stem of the dial indicator perpendicular to the

end of the shaft.

NOTE

: Place stem of dial indicator as close to the

center of the shaft as possible.

7. Record the reading of the dial indicator when the

indicator has engaged the shaft.

8. With a pry bar, push the inboard end of the shaft up;

reference Figure 6.4.1.

NOTE

: Use a constant swift force when pushing on the

pry bar. Excessive force not required. DO NOT rotate

shaft while pushing on shaft. The object is to lift the

shaft only.

9. Record reading of the dial indicator. Take the difference

between the two readings. The difference is the axial

bearing clearance.

NOTE

: 0.001” to 0.004” ( 0.025 to 0.102 mm) axial

bearing clearance is recommended. Do steps 3 thru 9

several times to insure an accurate measurement has

been made.

10. See Sections 6.4.2 and 6.4.3 for adjusting for too much

or too little axial bearing clearance.

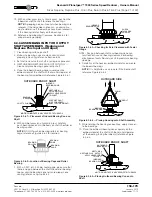

6.4.2 ADJUSTING FOR TOO MUCH AXIAL

BEARING CLEARANCE

NOTE

: If axial bearing clearance is too excessive, it might

be necessary to remove the clampnut and other hardware,

and press the bearing again. Reference Section 6.3.5 -

steps 11 to 20, or Section 6.3.6 - steps 12 to 21.

1. Loosen socket head cap screw on clampnut.

2. Mark the position of the clampnut.

3. Rotate clampnut 1/16” to 1/8” (1.5 to 3.1 mm) in the

clockwise direction from mark to tighten clampnut.

NOTE

: The measurement given is an estimate.

4. Follow procedures in Section 6.4.1 to determine new

axial bearing clearance.

5. Repeat first 5 steps if axial bearing clearance is found

to be still too much.

OUTBOARD END OF SHAFT

DIAL INDICATOR

HUB

C-CLAMP

SUPPORT

BLOCK

PRY BAR

SUPPORT

BLOCK

C-CLAMP

MAGNETIC

BASE

Figure 6.4.1 Setting Axial Bearing Clearance

Содержание CD-1261

Страница 1: ... 0 1 2121 3 4 1 5 6 ...

Страница 2: ... ...

Страница 3: ... ...

Страница 4: ... ...

Страница 5: ... ...

Страница 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Страница 7: ... ...

Страница 8: ... 0 1 2 0 3 0 ...

Страница 9: ... ...

Страница 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Страница 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Страница 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Страница 14: ... ...

Страница 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Страница 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Страница 18: ... ...

Страница 21: ... 1 A 0 0 1 7 0 0 1 1 7 2 1 2 1 B1 7 0 1 7 1 1 C 1 A 1 4 1 0 D199 5 6 1 4 1 A 1 81 0 0 0 0 1 7 1 1 1 ...

Страница 25: ... 8 ...

Страница 26: ... E 4 0 1 A 4 1 1 A 0 1 0 4 1 0 0 1 7 0 1 0 0 0 1 0 0 1 0 1 01 1 0 4 0 0 0 1 0 0 1 G 7 1 4 0 1 1 ...

Страница 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Страница 29: ... 4 ...

Страница 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Страница 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Страница 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Страница 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Страница 36: ... E 5 ...

Страница 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Страница 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Страница 39: ... 0 ...

Страница 40: ... 0 0 ...

Страница 42: ......

Страница 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Страница 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Страница 45: ... 011 2 3 4 5 5 3 2 3 2 3 5 5 5 5 5 55 2 3 5 2 6 2 6 6 5 6 6 5 6 5 2 6 5 6 2 2 2 2 2 5 5 2 2 2 2 7 5 ...

Страница 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Страница 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Страница 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Страница 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Страница 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Страница 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Страница 52: ... 011 2 3 2 4 5 3 5 5 5 5 6 5 3 22 7 22 3 22 7 22 7 5 22 7 7 7 5 5 5 5 2 5 5 52 5 2 2 5 2 5 2 5 2 ...

Страница 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Страница 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Страница 55: ... 0122 3 4 5 6 7 4 4 5 7 7 7 7 55 55 55 4 4 7 4 7 4 7 7 4 4 8 4 55 8 4 8 7 4 8 8 8 7 7 7 5 7 7 6 ...

Страница 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Страница 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Страница 58: ... ...

Страница 59: ... ...

Страница 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Страница 97: ......

Страница 98: ......

Страница 99: ......

Страница 100: ......

Страница 101: ......

Страница 102: ......

Страница 103: ......

Страница 104: ......

Страница 105: ......

Страница 106: ......

Страница 107: ......

Страница 108: ......

Страница 109: ......

Страница 110: ......

Страница 111: ......

Страница 112: ......

Страница 113: ......

Страница 114: ......

Страница 115: ......

Страница 116: ......

Страница 117: ......

Страница 118: ......

Страница 119: ......

Страница 120: ......

Страница 121: ......

Страница 122: ......

Страница 123: ......

Страница 124: ......

Страница 125: ......

Страница 126: ......

Страница 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Страница 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Страница 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Страница 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Страница 169: ... 0 255 02 9 B 29 529C C 2 9 3D 29 E 25 9 F 9B C D 33 A 9 3 2 D D D B G D 0 3 5 0 23B 9 3 3 2 D 90 5 9 3 3 3 D A2 2 D ...

Страница 194: ......

Страница 195: ......

Страница 196: ......

Страница 218: ......

Страница 219: ......

Страница 234: ...15 Notes Model 121 Regulators Brochure ...

Страница 236: ......

Страница 324: ... 6PDUW QIUDVWUXFWXUH 1 HQ LPHQVLRQV FRQW G 1RW WR VFDOH 9 9 6 9 0 5 3 7 8 1 2 4 9 4 9 4 4 SOXJ P HQ 9 LPHQVLRQV ...