Rexnord

®

Planetgear™ 7000 Series Speed Reducer

s

Owners Manual

Sizes Neptune, Neptune Plus, Orion Plus, Saturn Plus & Titan Plus (Page 21 of 32)

Rexnord

158-170

3001 W. Canal St., Milwaukee, WI 53208-4200

January 2015

Telephone: 414-937-4359 Fax: 414-937-4359 www.rexnord.com

Supersedes 11-12

19. With an arbor press or a hydraulic press, push on the

inboard end of the shaft to relieve the bearings.

NOTE

: A popping noise will sound when bearings are

relieved. If the noise does not occur , an alternative

way to determine if the bearings have been relieved is

if the housing rotates freely on the bearings.

20. Reference Axial Bearing Clearance, Section 6.4 for

proper bearing endplay.

6.3.6 ASSEMBLING INPUT OR OUTPUT

SHAFT ASSEMBLIES (Neptune and

Neptune Plus Input and Output)

1. Clean bearing surface on shaft.

2. Make sure bearing cups are clean and installed

properly in housing; reference Section 6.3.3.

3. Set shaft on end so that shaft is resting on spline end.

4. NEPTUNE AND NEPTUNE PLUS OUTPUT ONLY —

Clean and place bearing spacer onto shaft.

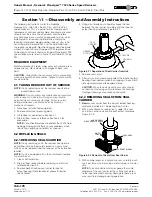

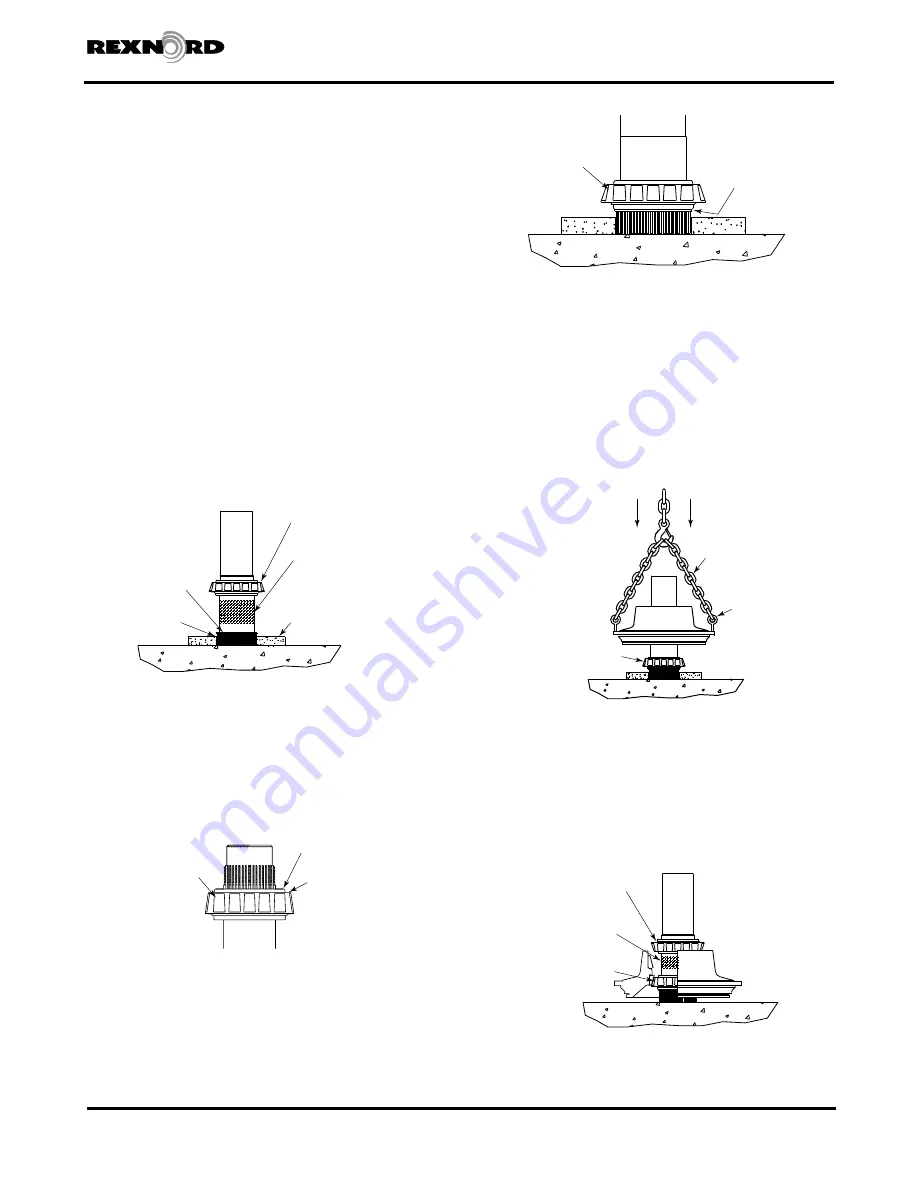

5. Place the inboard bearing cone squarely on the

outboard end of the shaft with the smaller diameter of

the bearing facing outboard; reference Figure 6.3.6.1.

OUTBOARD END OF SHAFT

NOTE

: DO

NOT

APPLY NEVERSEIZE TO THREADS

INBOARD

BEARING CONE

NEPTUNE &

SATURN OUTPUT

APPLY NEVERSEIZE

TO SHAFT

SUPPORT PILOT

(NOT TO EXCEED

SHAFT SPLINE HEIGHT)

BEARING

SPACER

SHAFT SPLINE

Figure 6.3.6.1—Placement of Inboard Bearing Cone on

Shaft

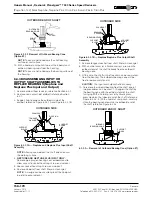

6. With an arbor press or a hydraulic press carefully

push bearing cone until it bottoms on shaft shoulder or

bearing spacer.

NOTE

: DO NOT push on bearing rollers or bearing

cage; reference Figure 6.3.6.2 for location.

BEARING

ROLLERS

BEARING

CONE

BEARING

CAGE

Figure 6.3.6.2—Location of Bearing Cage and Roller

Bearing

7. With a 0.001” or 0.040 mm feeler gage, make sure that

there is no gap between the shaft shoulder or bearing

spacer, and the bearing cone to insure proper cone

seating; reference Figure 6.3.6.3.

INBOARD

BEARING CONE

CHECK

THIS AREA

FOR GAP

Figure 6.3.6.3—Checking for Zero Clearance with Feeler

Gauge

NOTE: Any gap between shaft and bearing cone can

result excessive axial bearing clearance or bearing

misalignment and ultimately result in premature bearing

damage.

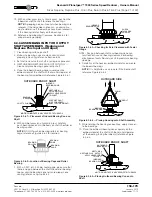

8. Carefully set the housing, outboard side face up, onto

the inboard bearings.

NOTE

: It is helpful to use a crane to lift hub onto shaft;

reference Figure 6.3.6.4.

OUTBOARD SIDE

CHAIN

EYE BOLT

INBOARD

BEARING CONE

Figure 6.3.6.4 — Placing Housing onto Shaft Assembly

9. While rotating the housing on bearings, apply clean oil

to the bearings.

10. Place the outboard bearing cone squarely on the

outboard end of the shaft with the smaller diameter

of the bearing facing the inboard; reference Figure

6.3.6.5.

OUTBOARD END OF SHAFT

NOTE: DO NOT APPLY NEVERSEIZE TO THREADS

OUTBOARD

BEARING CUP

NEPTUNE &

NEPTUNE PLUS OUTPUT

APPLY NEVERSEIZE

TO SHAFT

INBOARD

BEARING CUP

Figure 6.3.6.5—Placing Outboard Bearing Cone onto

Shaft

Содержание CD-1261

Страница 1: ... 0 1 2121 3 4 1 5 6 ...

Страница 2: ... ...

Страница 3: ... ...

Страница 4: ... ...

Страница 5: ... ...

Страница 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Страница 7: ... ...

Страница 8: ... 0 1 2 0 3 0 ...

Страница 9: ... ...

Страница 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Страница 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Страница 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Страница 14: ... ...

Страница 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Страница 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Страница 18: ... ...

Страница 21: ... 1 A 0 0 1 7 0 0 1 1 7 2 1 2 1 B1 7 0 1 7 1 1 C 1 A 1 4 1 0 D199 5 6 1 4 1 A 1 81 0 0 0 0 1 7 1 1 1 ...

Страница 25: ... 8 ...

Страница 26: ... E 4 0 1 A 4 1 1 A 0 1 0 4 1 0 0 1 7 0 1 0 0 0 1 0 0 1 0 1 01 1 0 4 0 0 0 1 0 0 1 G 7 1 4 0 1 1 ...

Страница 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Страница 29: ... 4 ...

Страница 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Страница 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Страница 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Страница 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Страница 36: ... E 5 ...

Страница 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Страница 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Страница 39: ... 0 ...

Страница 40: ... 0 0 ...

Страница 42: ......

Страница 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Страница 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Страница 45: ... 011 2 3 4 5 5 3 2 3 2 3 5 5 5 5 5 55 2 3 5 2 6 2 6 6 5 6 6 5 6 5 2 6 5 6 2 2 2 2 2 5 5 2 2 2 2 7 5 ...

Страница 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Страница 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Страница 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Страница 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Страница 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Страница 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Страница 52: ... 011 2 3 2 4 5 3 5 5 5 5 6 5 3 22 7 22 3 22 7 22 7 5 22 7 7 7 5 5 5 5 2 5 5 52 5 2 2 5 2 5 2 5 2 ...

Страница 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Страница 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Страница 55: ... 0122 3 4 5 6 7 4 4 5 7 7 7 7 55 55 55 4 4 7 4 7 4 7 7 4 4 8 4 55 8 4 8 7 4 8 8 8 7 7 7 5 7 7 6 ...

Страница 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Страница 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Страница 58: ... ...

Страница 59: ... ...

Страница 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Страница 97: ......

Страница 98: ......

Страница 99: ......

Страница 100: ......

Страница 101: ......

Страница 102: ......

Страница 103: ......

Страница 104: ......

Страница 105: ......

Страница 106: ......

Страница 107: ......

Страница 108: ......

Страница 109: ......

Страница 110: ......

Страница 111: ......

Страница 112: ......

Страница 113: ......

Страница 114: ......

Страница 115: ......

Страница 116: ......

Страница 117: ......

Страница 118: ......

Страница 119: ......

Страница 120: ......

Страница 121: ......

Страница 122: ......

Страница 123: ......

Страница 124: ......

Страница 125: ......

Страница 126: ......

Страница 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Страница 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Страница 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Страница 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Страница 169: ... 0 255 02 9 B 29 529C C 2 9 3D 29 E 25 9 F 9B C D 33 A 9 3 2 D D D B G D 0 3 5 0 23B 9 3 3 2 D 90 5 9 3 3 3 D A2 2 D ...

Страница 194: ......

Страница 195: ......

Страница 196: ......

Страница 218: ......

Страница 219: ......

Страница 234: ...15 Notes Model 121 Regulators Brochure ...

Страница 236: ......

Страница 324: ... 6PDUW QIUDVWUXFWXUH 1 HQ LPHQVLRQV FRQW G 1RW WR VFDOH 9 9 6 9 0 5 3 7 8 1 2 4 9 4 9 4 4 SOXJ P HQ 9 LPHQVLRQV ...