)

SKP15=U Electro-hydraulic Actuators

Technical Instructions

Document Number 155-751

July 9, 2014

Siemens Building Technologies, Inc.

Page 3

Operation

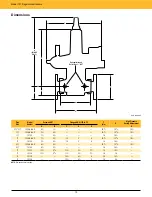

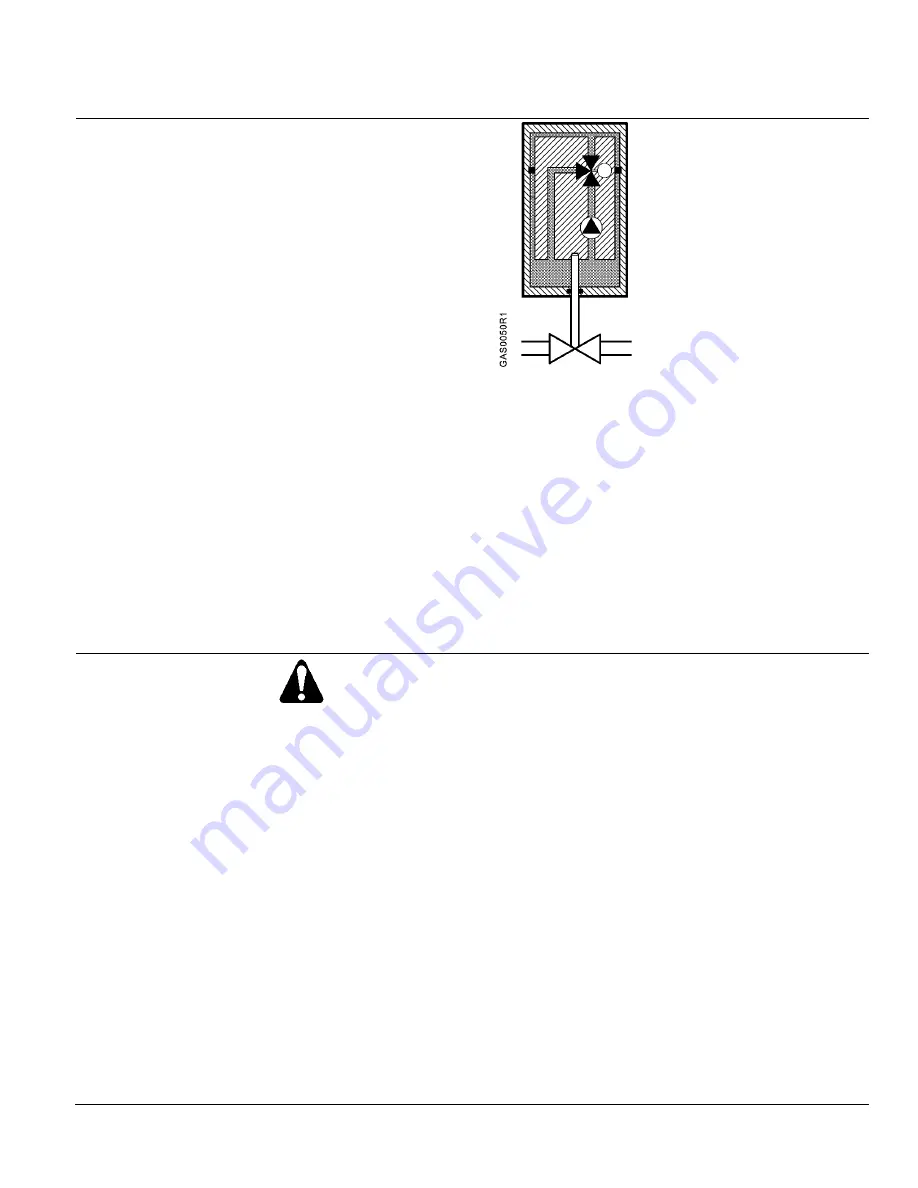

Figure 1. SKP155 Operation.

The electro-hydraulic actuator consists of a cylinder filled with oil, a piston containing an

electric oscillating pump, and a relief system. When power is supplied to the actuator, the

relief system closes, and the pump moves oil from the reservoir into the pressure

chamber. This action causes the piston to move downward in the cylinder, opening the

gas valve. When power to the actuator is interrupted, the relief system opens and the gas

valve closes in less than 0.8 seconds.

A position indicator, visible through the transparent portion of the terminal cover, shows

the entire stroke range of the actuator. A light, which is visible through the lower left

transparent portion of the terminal cover, indicates when the actuator receives power. An

optional, non-adjustable SPDT proof of closure over travel switch signals the closed

position after the gas valve has closed. An optional SPDT auxiliary switch is adjustable

between 40% and 100% of the stroke. The adjustment screw and scale are located on

the right side in the terminal box, and are visible through the transparent portion of the

terminal cover.

Installation

WARNING:

•

Personal injury or loss of life may occur if procedures are not followed

as specified.

•

All installations must be performed by qualified personnel only.

•

Do not pull the actuator shaft.

•

The AGA66 gasket must be installed between the actuator and the

gas valve body to provide NEMA 3, 3R, and 4 protection rating for

VGG= and VGD= valves.

•

The SKP15= actuator is directly coupled to the VG= series valve body by four pre-

mounted 4 mm Allen key screws.

•

The square mounting flange can be rotated in steps of 90

o

to provide four different

mounting positions. The SKP15= actuator can be mounted in any position except

upside down.

•

The actuator can be mounted or replaced while the valve body is under pressure.

•

The SKP15= actuator has two knock-outs for the installation of 1/2”-14 NPSM

conduit connections.

•

When conduit routing is connected, flexible conduit must be used.

•

Liquid tight conduit must be used in combination with AGA66 to provide NEMA 3, 3R,

and 4 protection.

•

The terminal marked GND, located above the wiring terminals, must be connected to

the electrical ground.

Содержание CD-1261

Страница 1: ... 0 1 2121 3 4 1 5 6 ...

Страница 2: ... ...

Страница 3: ... ...

Страница 4: ... ...

Страница 5: ... ...

Страница 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Страница 7: ... ...

Страница 8: ... 0 1 2 0 3 0 ...

Страница 9: ... ...

Страница 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Страница 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Страница 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Страница 14: ... ...

Страница 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Страница 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Страница 18: ... ...

Страница 21: ... 1 A 0 0 1 7 0 0 1 1 7 2 1 2 1 B1 7 0 1 7 1 1 C 1 A 1 4 1 0 D199 5 6 1 4 1 A 1 81 0 0 0 0 1 7 1 1 1 ...

Страница 25: ... 8 ...

Страница 26: ... E 4 0 1 A 4 1 1 A 0 1 0 4 1 0 0 1 7 0 1 0 0 0 1 0 0 1 0 1 01 1 0 4 0 0 0 1 0 0 1 G 7 1 4 0 1 1 ...

Страница 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Страница 29: ... 4 ...

Страница 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Страница 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Страница 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Страница 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Страница 36: ... E 5 ...

Страница 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Страница 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Страница 39: ... 0 ...

Страница 40: ... 0 0 ...

Страница 42: ......

Страница 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Страница 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Страница 45: ... 011 2 3 4 5 5 3 2 3 2 3 5 5 5 5 5 55 2 3 5 2 6 2 6 6 5 6 6 5 6 5 2 6 5 6 2 2 2 2 2 5 5 2 2 2 2 7 5 ...

Страница 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Страница 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Страница 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Страница 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Страница 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Страница 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Страница 52: ... 011 2 3 2 4 5 3 5 5 5 5 6 5 3 22 7 22 3 22 7 22 7 5 22 7 7 7 5 5 5 5 2 5 5 52 5 2 2 5 2 5 2 5 2 ...

Страница 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Страница 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Страница 55: ... 0122 3 4 5 6 7 4 4 5 7 7 7 7 55 55 55 4 4 7 4 7 4 7 7 4 4 8 4 55 8 4 8 7 4 8 8 8 7 7 7 5 7 7 6 ...

Страница 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Страница 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Страница 58: ... ...

Страница 59: ... ...

Страница 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Страница 97: ......

Страница 98: ......

Страница 99: ......

Страница 100: ......

Страница 101: ......

Страница 102: ......

Страница 103: ......

Страница 104: ......

Страница 105: ......

Страница 106: ......

Страница 107: ......

Страница 108: ......

Страница 109: ......

Страница 110: ......

Страница 111: ......

Страница 112: ......

Страница 113: ......

Страница 114: ......

Страница 115: ......

Страница 116: ......

Страница 117: ......

Страница 118: ......

Страница 119: ......

Страница 120: ......

Страница 121: ......

Страница 122: ......

Страница 123: ......

Страница 124: ......

Страница 125: ......

Страница 126: ......

Страница 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Страница 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Страница 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Страница 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Страница 169: ... 0 255 02 9 B 29 529C C 2 9 3D 29 E 25 9 F 9B C D 33 A 9 3 2 D D D B G D 0 3 5 0 23B 9 3 3 2 D 90 5 9 3 3 3 D A2 2 D ...

Страница 194: ......

Страница 195: ......

Страница 196: ......

Страница 218: ......

Страница 219: ......

Страница 234: ...15 Notes Model 121 Regulators Brochure ...

Страница 236: ......

Страница 324: ... 6PDUW QIUDVWUXFWXUH 1 HQ LPHQVLRQV FRQW G 1RW WR VFDOH 9 9 6 9 0 5 3 7 8 1 2 4 9 4 9 4 4 SOXJ P HQ 9 LPHQVLRQV ...