LINCOLN GmbH • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259 • Tx 466088

Subject to modifications

Owner Manual

Technical Description

Page 5 from 13

2.1A-28001-A94

After the reservoir has been filled with the recommended lubricant

the counter nut of the vent screw must be loosened and the vent

screw opened by maximum one turn ( DO NOT REMOVE).

Also disconnect the main lines from the metering device inlets. Acti-

vate the pump until lubricant is emerging at the vent screw. Then

retighten first the vent screw and then the counter nut. Continue to

activate the pump until lubricant is emerging from the disconnected

main lines. Then re-tighten the inlet fittings of the metering device.

Repeat this procedure until all main lines are filled.

Feed lines

It is advisable to fill each feed line with lubricant before it is connected

with the metering device outlet.

Filling instructions for model PP4

Remove pump reservoir with cover.

Immerse open part of pump reservoir into grease. Pull piston guide

rod vigorously upwards and lock it into groove. Avoid air inclusions.

Screw reservoir onto pump. Release guide rode (central position).

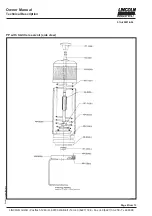

Commissioning of the system

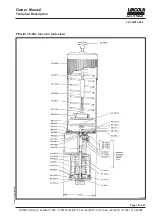

Lubrication system with main metering device

Lubrication system with main and secondary metering devices

Typical outlet combination

Pump and main lines

1011a97a

1010a97