LINCOLN GmbH • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259 • Tx 466088

Page 4 from 13

Owner Manual

Technical Description

2.1A-28001-A94

Subject to modifications

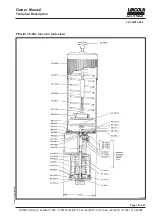

Quicklub Grease Pump Model PP

Description

The QUICKLUB pump model PP is designed for use with progressi-

ve typ centralized lubrication system. It is a pneumatically operated

single-stroke pump with spring-loaded follower plate requiring a 3/

2-way valve for activating the air cylinder. It has a control rod for

lubricant level.

Operation

When the solenid is energized, compressed air enters the air cylin-

der bottom

and moves the piston moves upward, the ball seat of the suction

valve presents the lubricant from returning to the lubricant reservoir.

Lubricant is therefore dispensed from the outlet of the pump.

When the solenid is de-energized, the compressed air leaves the air

cylinder. The piston spring moves the piston downward. The ball of

the suction valve unseats allowing lubricant from reservoir to refill the

discharge cavity in the pump bodey for the next lubrication cycle.

Important: The pump must be installed in vertical position!

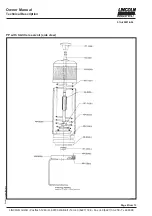

Filling of reservoir

It is advisable to fill the reservoir via the hydraulic lubrication fitting

251-14045-1 located at the base of the pump reservoir. Either use a

pneumatic or a manual grease pump. Reservoir must be filled until

the recessed ring appears on the follower rod at the top of the reser-

voir. The above applies only to pumps of model PP 15.

For pumps of model PP 4 refer to Filling Instructions on page 4

(folded page).

Important: Avoid air inclusions!

Technical Data

Pump pressure ratio

.................................. 40:1

Air pressure

.................................. min. 4 bar

.................................. max.10 bar

Max. operating pressure ................................ 300 bar

Air inlet

.................................. G1/8“

Lube outlet

.................................. dia 6 mm

Lubricant output per pump stroke ................... 2,6 cm

3

Reservoir capacities

PP 15 ......................... 1,5 l

PP 4 ........................... 0,4 l

Model

Part No.

PP 4

604-25104-1

PP 15

604-25105-2