B - DESCRIPTION

8695 9007 / F

B-4

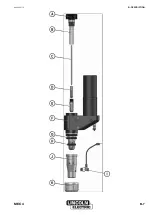

MEC 4

Both versions offer the following possibilities:

Easy removal of the electrode holder from the top of the torch body, for more

speed and no risk of upsetting the mechanical adjustment of the torch.

Pre-adjustment (outside the torch) of the emerged length of the electrode in

relation to the end of the protective nozzle. That pre-adjustment is carried out with

an adjustable tool delivered with the torch.

The parallelepiped shape of the outer body of the torch makes it easier to take

a positioning reference.

The

MEC4

torch is cooled by water circulation and can easily withstand the

most stringent welding requirements up to 500A at 100% (except version

W000315610, limited to 250A at 100%.

As an option, straight and bent

MEC 4

torches may be instantly fitted with the

following additions:

Nozzle with electromagnetic circuit for welding with arc oscillation or

deviation

Large diameter (6.0, 6.4 or 7 mm) electrode holder for high-intensity AC

welding of light allows.

Trailing shield additional to the nozzle for all applications requiring a high

degree of gas shielding for the melted metal. That trailing shield option is

compatible with arc oscillation.

2 - CHARACTERISTICS OF THE

MEC 4

TORCH

Version with screw-

on fittings

Quick Connector

(QC) version

Manual version

Part number

Straight

W000315606

W000315611

W000315610

Bent

W000315607

W000315612

Maximum intensity

500A / 100%

250A / 100%

Weight of torch alone, ready to weld

2.6 Kg

Bundle length

1.1 m

2 m

8 m

Cooling

Number of circuits

1 water circuit

(out and back)

1 hollow fitting

quarter turn

connector

for manual station

Min. output

2.5 l/min at 3.5 bar

Striking

Principle

Double HF emission

Annular gas

Argon

10 to 38 l/min

Argon/H2

Argon/He

Helium