8695 9007 / F

C - USE

MEC 4

C-11

4 - ADJUSTING THE ELECTRODE IN THE

MEC4

TORCH

The erosion of the tip of the electrode during welding is significantly determined by

the purity of its gas shield, and shielding is in principle ideal at a relatively small

distance from the orifice of the torch nozzle.

The greater the emerged length of the electrode (the arc length must be added to

that length), the greater the gas flow must be, and it can be disrupted by the flow of air

in the neighbouring area:

torch movement

movement of tooling in the vicinity

ventilation or aeration close to the welding equipment.

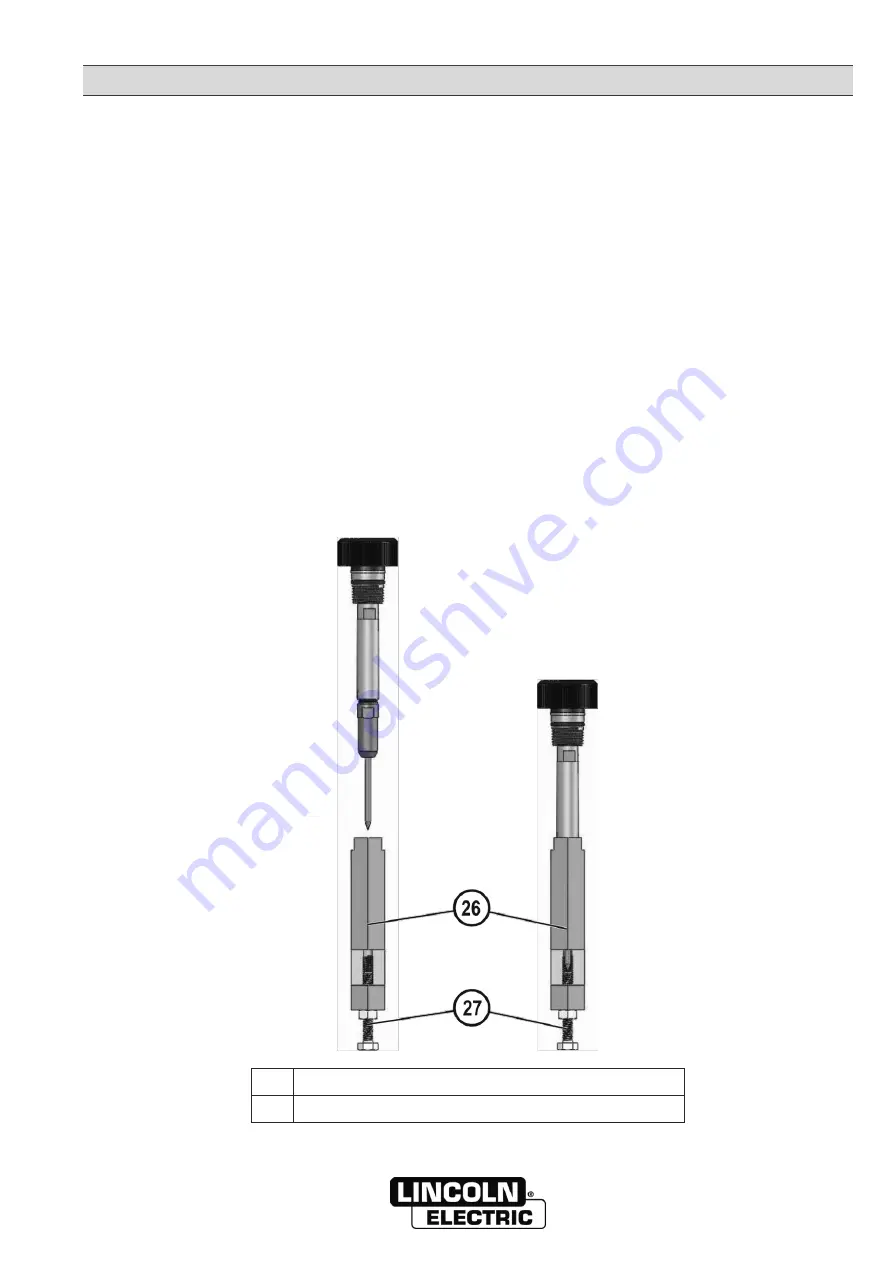

In practice, the tool supplied with the

MEC 4

torch should be adjusted so that the

electrode emerges out of the nozzle by 2 to 3 mm.

Once the tool is adjusted, electrode replacements can be made rapidly with no

adjustment, with the certainty of finding the same position.

Proceed as follows:

immobilise the electrode adjustment tool in a vice, for example

position the electrode in the electrode holder without tightening the clamp seat

too firmly, so that the electrode can still slide

insert the electrode holder in the tool by engaging the two flats fully, then

tighten the electrode holder with the 10mm spanner. The tip of the electrode

must then stop against the adjusting screw.

The length of the electrode that emerges out of the nozzle is obtained for the first

time by successively adjusting that screw immobilised by a lock nut.

26

Electrode adjustment tool

27

Adjustment