Suzhou Lily Tech. Co., Ltd.

Page 3, Total 8 Pages

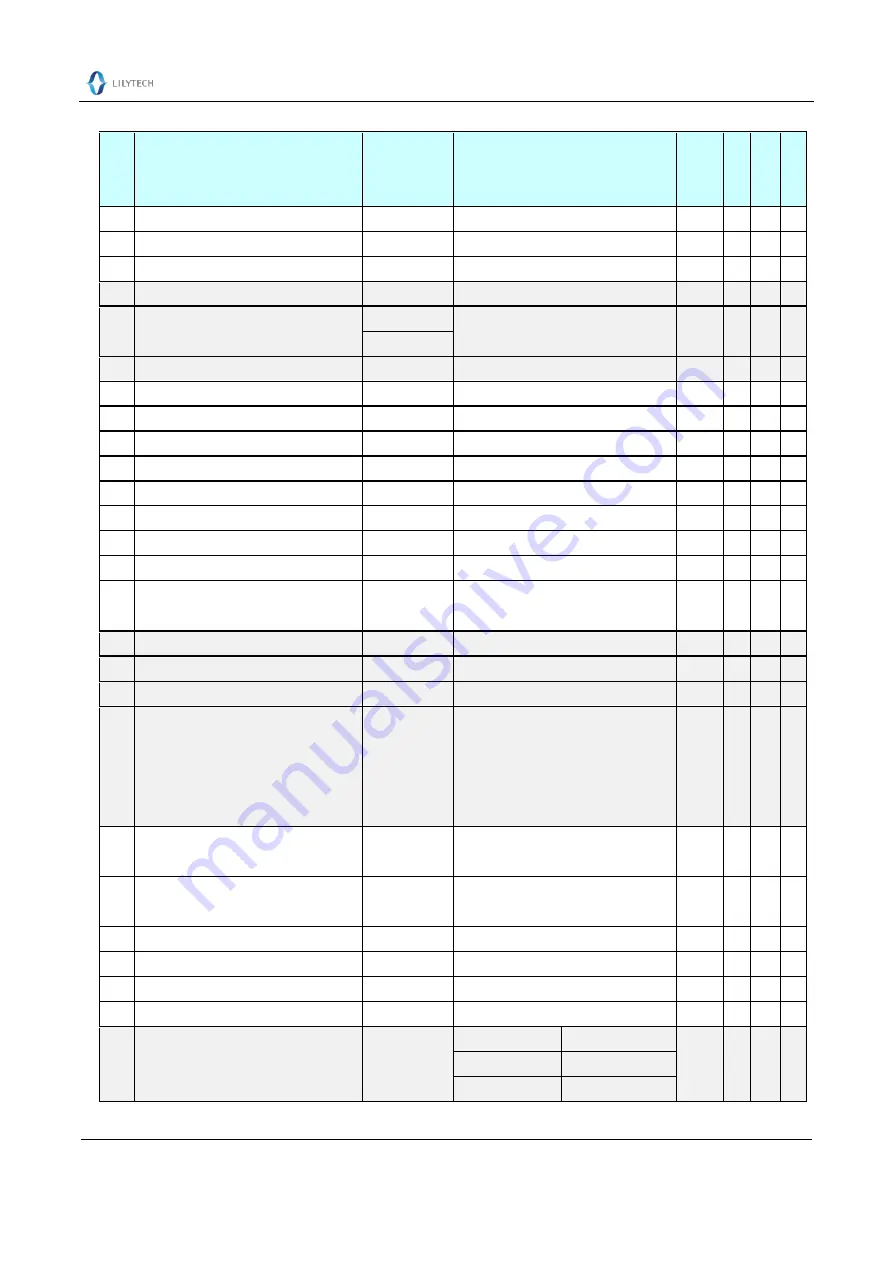

Parameter Code Table

Code

Function

Range

Remark

Factory

default

ZL

-610A

ZL

-620A

ZL

-630A

U10 Temp. output stop protection time

0~100 min

3

●

●

●

U11 Temp. output run protection time

0~100 min

3

●

●

●

U12 Temp. output run frequency

0~8

Only for cooling mode, 0 = disable

5

●

●

●

U20 Room sensor calibration

-9.9~+9.9

℃

0

●

●

●

U21 Pipe sensor calibration

-9.9~+9.9

℃

di = disable pipe sensor (also disable

defrost function)

0

/

●

●

di

U22 Hysteresis

0.1~+10.0

℃

See paragraph 6.1 and 6.2

1

●

●

●

U30 Defrost period

0~180 hour

0 = disable defrost

6

●

●

●

U31 Defrost time

1~180 min

30

●

●

●

U32 Defrost finish temp.

0.5~50

℃

12

/

●

●

U33 Dripping time

0~180 min

5

●

●

●

U34 Over temp. warning delay after defrost 0~180 hour

0 = disable

2

●

●

●

U35 Defrost after online

0~1

0 = disable, 1 = enable

0

●

●

●

U36 Delay for

defrost after online

0~180 min

0 = disable

0

●

●

●

U38 Defrost type

0~1

0 = Electrical, 1 = Gas or pump

0

●

●

●

U39

Defrost finish sensor

0~1

0: based on timer only

1: based on pipe temperature

1

/

●

●

U40 Fan start temp.

-45~+120

℃

-10

/

/

●

U41 Fan start delay

0~600 sec

60

/

/

●

U42 Fan stop delay

0~600 sec

0

/

/

●

U43 Fan control mode

0~

4

0: Controlled mode (see 6.4)

1: Stop in defrosting, see 6.4

2: Stop in defrosting, else running

3: Run in defrosting, see 6.4

4: Run in defrosting, else running

0

/

/

●

U44

Fan run time when compressor stops

during cooling mode

0~60

min

Only effective when U43 = 1 or 3

0

/

/

●

U45

Fan stop time when compressor stops

during cooling mode

0~60

min

Only effective when U43 = 1 or 3

0

/

/

●

U50 Deviation for high temp. warning

0~60

℃

0 = disable

10

●

●

●

U51 Deviation for low temp. warning

0~60

℃

0 = disable

6

●

●

●

U52 Over temp. warning delay

0~180 min

30

●

●

●

U53 Over temp. warning delay after online 0~180 hour

0 = disable

2

●

●

●

U60 External warning input mode

0~4

0 = disable

3 = NC, locked

0

●

●

●

1 = NO, locked

4 = NC, unlocked

2 = NO, unlocked