LIGHT PROGRESS

STICK-ST [Eng.]

Rev. 2 Oct 2020

Page

4

of

15

DEVICE DESCRIPTION

The UV STICK E2/75H-ST-NX-NT

is a dual lamp

germicidal device, placed on a stand with four wheels

for easy mobility. It works on direct radiation at 360

degrees and sterilizes irradiated air and surfaces. The

UV-C lamps, with an emission peak at 235.7 nm.

(nanometres) have a strong germicidal power against

all micro-organisms (moulds, bacteria and viruses).

Installed UV Stick (Picture 1):

A)

Metal stand

: painted steel base plate, with 4

swivelling wheels.

B)

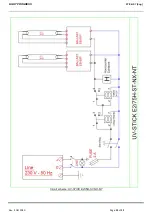

Control Unit

: stainless steel (AISI 304), equipped

with a bipolar magneto-thermal switch, two rotary

knobs for ignition delay and treatment duration setting,

start/stop button, hour meter for UV lamps

replacement.

C)

UV unit

: 2 UV-lamps, protected by stainless

steel

grid (AISI 304). The body is made of stainless steel

with mirror polished aluminium reflector, which

increases performance reflecting a higher percentage

of UV-C rays.

APPLICATIONS AND RESULTS

Each UV-STICK series can be installed in any type of

environment to achieve a deep disinfection of air and

surfaces, even those difficult to be reached by

traditional systems.

When turned on, there is a strong reduction of microbes

in the air and on surfaces. For example, in 8 minutes at

a distance of 3 meters, it achieves a 99% reduction of

bacteria such as: Bacillus coli, Clostridium, Legionella,

Vibrio, Salmonella, Pseudomonas, Staphylococcus,

Streptococcus, etc..

Thanks to natural air circulation, even microbes located

in hidden areas are continually drawn towards the

irradiated area, so that their overall level progressively

decreases.

Usage of the UV Stick is permitted

only

in absence of

staff or if radiation is adequately shielded.

The device can operate during personnel break from

Pic.1

work. Timer can be used to manage the switching off

immediately before the start of work, so that workers

can have perfectly disinfected room.

Switching on and off is triggered by dedicated control unit, equipped with two timers to manage

ignition delay and treatment duration.