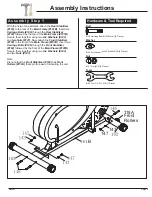

A s s e m b l y S t e p 2

Pivot Tube(See Note)

QM893

Page 7

Note:

Make sure

Left /Rgiht Coupler Bar (104L/104R)

are at the correct side when its horizontal pivot tube, which is

welded at the top, faces the

REAR

of the machine as seen from the user.

B

B

Washer

#156 Washer

(φ10.2xφ25x2 mm)

[2 Pieces]

#145 Nylon Nut (M10)

[2 Pieces]

Others

#112 Handlebar

Axle (φ16x410 mm)

[1 Piece]

#142 Cap

(S17)

[2 Pieces]

Tools

#168 T

ool 1 (2-S17,S19)

[2 Pieces]

Hardware & Tool Required

Remove the

Nylon Nuts (#145)

and

Washers (#156)

that

are pre-assembled on the

Handlebar Axle (#112)

and set

them aside as they will be used in a later process.

Insert the

Handlebar Axle (#112)

through the main frame.

Make sure the

Handlebar Axle (#112)

is centered. If you

encounter too much friction, try using WD40 or

Vaseline as

a lubricant.

Attach

Left Coupler Bar (#104L)

and

Right Coupler Bar

(#104R)

to the main frame via the

Handlebar Axle (#112)

.

Again, use WD40 or

Vaseline to reduce friction if needed.

Once the

Left Coupler Bar (#104L)

and

Right Coupler

Bar (#104R)

are correctly situated, fasten the end of the

Handlebar Axle (#112)

with a

Washer (#156)

and a

Nylon

Nut (#145)

on each side. Then cap each end with a

Cap

(#142).

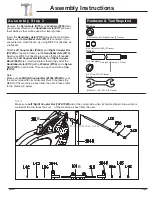

Note:

Make sure

Left/Right Coupler Bar (#104L/#104R)

are at

the correct side when its horizontal Pivot Tube faces the

REAR of the machine as seen from the user. Please refer

to the drawing in below.

55

40

1

2 3

4

55

40

1

2

3

4

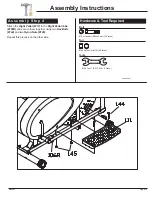

STEP3:

Assembly Instructions

Содержание BR1820

Страница 18: ...This page intentionally left blank...

Страница 19: ...Proof of Purchase version 01 03 2018 QM893 Model Number QM893...

Страница 20: ...Made in China...