-5-6-

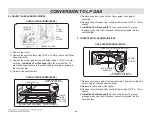

CONVERSION TO LP GAS

NOTE: When converting the unit back to natural gas the upper bake

burner’s air shutter should also be fully open.

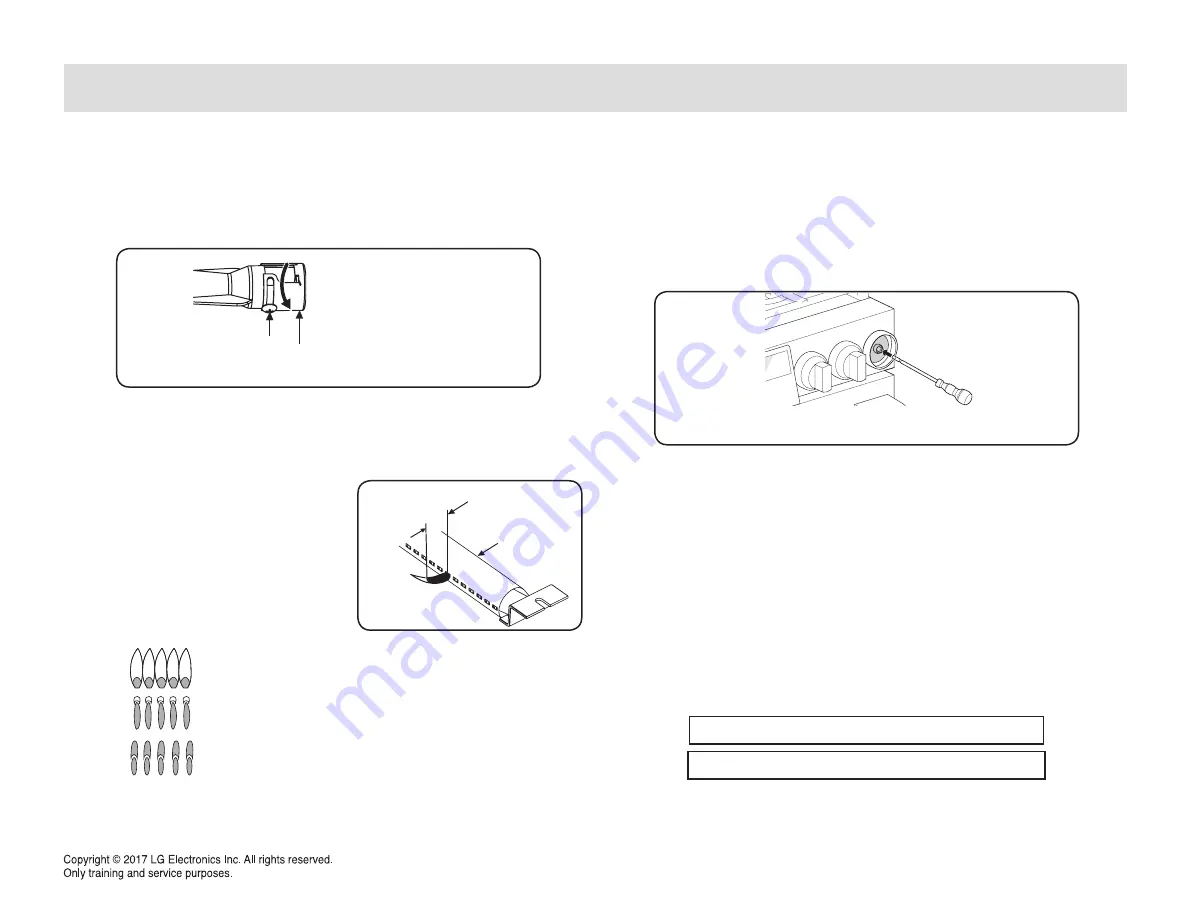

To adjust the air shutter on the broil burner for LP gas, loosen the

Phillips head screw and rotate the shutter fully open.

NOTE: When converting the unit back to natural gas the broil burner’s

air shutter should be fully open.

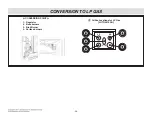

Fig. 1

Counterclockwise to

0.4 inch(10 mm) open position.

Screw

Air Shutter

Check the flame size. The flame should have approximately 1-inch blue

cones.

After operating the burner for 30

seconds, check for flame stability.

If the flame is lifting off of the burner

ports, gradually reduce the air shutter

opening until flames have stabilized.

Some yellow tipping may be normal

when used on LP. See Step 8.

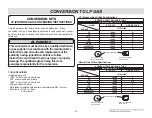

7. CHECK FLAME QUALITY

The combustion quality of the burner flames needs to be determined

visually.

A. Yellow Flames:

Further Adjustment Required

B. Yellow tips on outer cones:

Normal for LP Gas

C. Soft Blue flames:

Normal for Natural Gas.

NOTE: If burner flames look like A, further air shutter adjustment is required.

B or C is normal for burner flames, depending on the type of gas used. With

LP gas, some yellow tipping on the outer cones is normal.

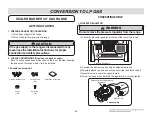

8. ADJUST SURFACE BURNER LOW FLAME (SIMMER) SETTING

1) Light all surface burners.

2) Turn the knob on the burner being adjusted to LO.

3) Remove knob.

4) Insert a small, flat blade screwdriver into the valve shaft as shown in Fig.

1. Turn the adjustment screw until the flame reaches the desired size.

5) Replace the knob.

Note: Hold the valve shaft with one hand while turning the screw for

adjustment with the other.

Fig. 1

Center adjustment screw

6) Test The Flame Stability.

Test 1: Turn the knob from HI to LO quickly. If the flame goes out,

increase the flame size and test again.

Test 2: With the burner on a LO setting, open and close the oven door

quickly. If the flame is extinguished by the air currents created by

the door movement, increase the flame height and test again.

7) Repeat steps 1-5 for each surface burner.

8. CONVERSION STICKER

Upon completion of the conversion, fill out the LP sticker located with

the instructions. Once complete, attach the sticker to the back of the

range near the regulator. Place all orifices that were removed for natural

gas back into the plastic bag along with the instructions. Place the kit

back into its original location. If converting back to natural gas from LP

remove the LP sticker from the back of the range.

CONVERSION IS FINISHED

To convert to the original gas.

Follow conversion process with original orifices to convert the appliance to the

original gas.

Note: The choke for the 18.5K/17K top burner must be removed when converting

the range back to natural gas.

Approx. 1”

INNER CONE

OF FLAME

OVEN

BURNER

Содержание LUTG4519SN

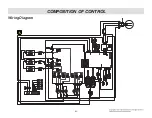

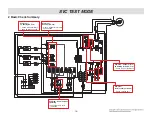

Страница 63: ... 6 1 COMPOSITION OF CONTROL Wiring Diagram ...

Страница 66: ... 6 4 COMPOSITION OF CONTROL P N EBR80595412 Oven Relay PCB CN53 CN51 CN52 ...

Страница 67: ... 6 5 COMPOSITION OF CONTROL SMPS PCB Touch PCB P N EBR80595701 P N EBR82864102 CN02 CN01 CN1 ...

Страница 99: ...UPPER DOOR PARTS EV 1021 1009 170R 1035 1035 170L 1015 1020 173U 173U 1008 102S 102S 102L W243 1000 W222 1801 ...

Страница 100: ...LOWER DOOR PARTS EV 1041 1009 1115 1120 102L 1018 173L 102U W243 W222 W222 1100 1704 1704 102L 173L 102U W101 W101 1801 ...

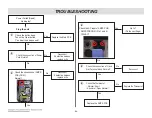

Страница 105: ......