should not be subject to vibrations.

The seals should be able to withstand the

forces engaged during normal motor operation,

as well as a possible over-torque of 2.5 times

the rated torque.

If atmospheric pollution is a problem the

following solutions are available : air filter,

ducting of cables, etc: see technical catalogue

ref. 1337… pages 50 & 80 for cooling methods,

page 129 for options.

The motor terminals and inspection doors

should be easily accessible to facilitate repairs

and maintenance.

Connection

See section

4.1 page 2 of the general

manual.

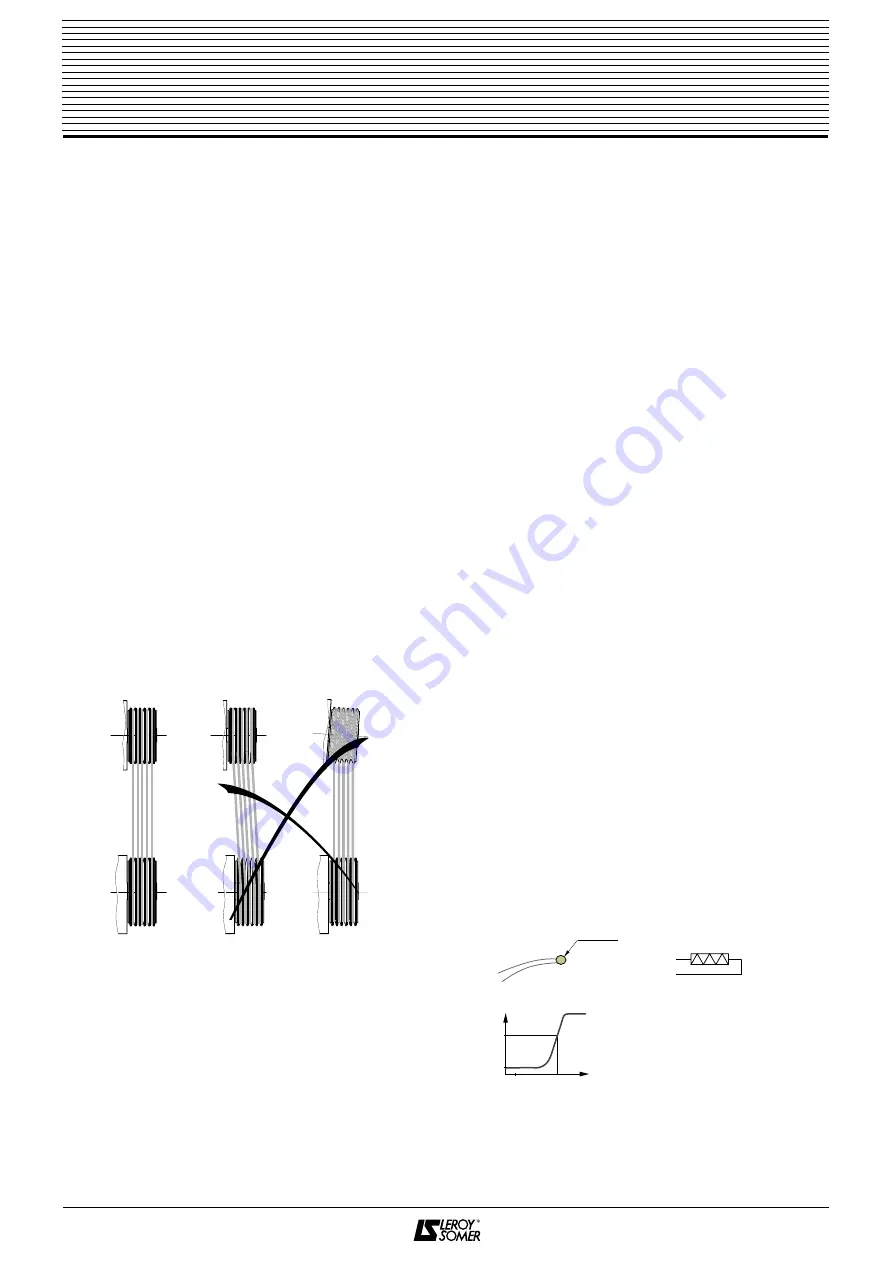

Check the connections are correctly aligned

(see figure 5).

For pulley and belt installations, compatilibity

of the forces (radial and axial) exerted on the

shaft MUST be compared to those listed in

the relevant sections of the technical

catalogue reference 1337.

For sleeve couplings a sufficient gap should

be left between the two coupling halves to

allow thermal expansion without axial thrust.

Do not use tools which jolt or bang the motor

as this may damage the bearings.

6. - ELECTRICAL CONNECTION

See section 4.2 page 3 of the general manual. Re-

fer to the diagrams for details on how to connect

the motor.

In the motor power circuit we recommend that

there is :

-

thermal protection by integration of overload

(100% of supply current);

-

instantaneous protection (200% of supply

current);

- protection against ground faults;

- protection against field overvoltages: if there is a

short-circuit in the field coil supply, place a resistor

R

p

in parallel with the field coil. For example :

R

p

= 800

x

U

exc

/ P

exc

where

R

p

parallel resistance in

Ω

,

U

exc

field voltage in V,

P

exc

field power supply in W.

Do not forget to connect the earth terminal to earth.

6.1 - Thermal detection

If a shorter protection reaction time is required, or

if you want to detect transient overloads and

monitor temperature rises at "hot spots" in the

motor or at strategic measured points in the

installation for maintenance purposes, installation

of heat sensors at "sensitive" points is

recommended. The various types are described

below.

NB : Heat sensors do not themselves protect the

motor.

Motors can be fitted with the following types of

thermal detector :

• thermistor (PTC probe : diag. 6)

These are thermovariable resistors with positive

temperature coefficients (marked with black flag-

type labels -trip- or blue -alarm-). When there is

an increase in temperature, the probe resistance

increases slowly then very quickly within a range

of

±

5

°

C of the nominal running temperature

(NRT).

The resistance value measured

at R terminals must be less

than 250

Ω

at the ambient tem-

perature.

Max. voltage : 2.5 V per probe.

4

LSK

D.C. motors

☞

Fig. 5

Ø ~3 mm

Fig. 6

R

NRT

T

0

250

1350

Ω

20

°C