Page 19

D

Burner motor is de−energized.

4.

Action: Established flame fails

Response:

D

Burner motor is de−energized and oil primary con-

trol goes into recycle mode.

D

If the fan off delay is longer than the recycle timing,

the heat fan continues to run through the next trial

for ignition.

5.

Action: Limit Switch Opens

Response:

D

Oil primary control shut off the burner.

D

Circulating fan is energized immediately at cool

speed.

D

A15 control board opens oil primary control T−3T

connections.

D

Circulating fan runs as long as limit stays open.

6.

Action: Limit Switch Closes

Response: If there is a heat demand, A15 control

board energizes oil primary control, initiating burner

light off.

Troubleshooting

Burner failure or improper operation can result from a num-

ber of different causes. Often the cause can be pinpointed

by observing the different types of failure or by the process

of elimination. The following troubleshooting charts list

some failures, causes and a sequence of steps to isolate

the point of failure. Check the simplest and most obvious

items before progressing to other items.

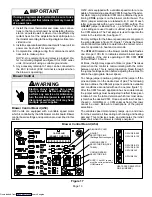

Troubleshooting: Burner fails to start

Source

Procedure

Causes

Correction

Thermostat

Check thermostat settings.

Thermostat in

OFF

or

COOL

Switch to

HEAT

.

Thermostat is set too low

Turn thermostat to higher temperature.

Safety

Overloads

Check burner motor,

primary safety control, &

auxiliary limit switch.

Burner motor overload

tripped

Push reset button pump motor.

Primary control tripped on

safety

Reset primary control.

Auxiliary limit switch tripped

on safety

Reset auxiliary limit.

Power

Check furnace disconnect

switch & main disconnect.

Open switch

Close switch.

Blown fuse or tripped circuit

breaker

Replace fuse or reset circuit breaker.

Thermostat

Touch jumper wire across

thermostat terminals on

primary control. If burner

starts, then fault is in the

thermostat circuit.

Broken or loose thermostat

wires

Repair or replace wires.

Loose thermostat screw

connection

Tighten connection.

Dirty thermostat contacts

Clean contacts.

Thermostat not level

Level thermostat.

Faulty thermostat

Replace thermostat.

CAD Cell

Disconnect the flame

detector wires at the

primary control. If the

burner starts, fault is in the

detector circuit.

Flame detector leads are

shorted

Separate leads.

Flame detector exposed to

light

Seal off false source of light.

short circuit in the flame

detector

Replace detector.

table continued on next page

Downloaded from