Page 14

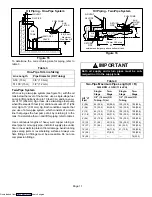

ADJUST

The

ADJUST

pins allow the motor to run at normal speed,

approximately 15% higher than normal speed, or 15% low-

er than normal speed. Table 6 gives three rowsNORM,

(+), and (–) with their respective CFM volumes. Notice that

the normal NORM" adjustment setting for cool speed

position C in table 6 is 800 CFM. The (+)" adjustment set-

ting for that position is 920 CFM (115% of 800 CFM) and

the (–)" adjustment setting is 680 CFM (85% of 800 CFM).

After the adjustment setting has been determined, choose

the remaining speed settings from those offered in the

table in that row.

The TEST pin is available to bypass the blower control and

run the motor at approximately 70% to make sure that the

motor is operational. This is used mainly in troubleshoot-

ing. The G terminal must be energized for the motor to run.

COOL (single-stage systems)

The

COOL

jumper is used to determine the CFM during

cooling operation. This jumper selection is activated for

cooling when Y1 is energized. Y1 and Y2 must be jump-

ered for single stage cooling.

The blower motor runs at 82% CFM for the first 7−1/2 min-

utes of each cooling demand to allow for greater humidity

removal and to conserve energy. If, after 7−1/2 minutes,

the Y demand is not met, 100% CFM is supplied until the

demand is satisfied.

OFF

CALL

100%

82%

Y

60

sec

7.5 minutes

82%

y

Y − Cool Demand Present

y − Cool Demand Satisfied

When the demand for cool is met, the blower ramps down

to 82% CFM for 60 seconds, then turns off.

COOL (two-stage systems)

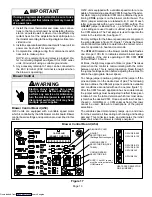

IMPORTANT

The unit is factory set for single−stage cooling. For

two−stage cooling operation, the jumper wire from

Y1 to Y2 on the blower control board must be cut (at

terminal Y1) and connected to Y2 from the thermo-

stat (A54 board Y2" to thermostat Y2"). See figure

18 wiring diagram.

A thermostat call for first-stage cooling closes the R to Y1

circuit on the A54 blower control board. The blower motor

runs at 57% CFM for the first 7−1/2 minutes of the 1st−stage

cooling demand. After 7−1/2 minutes, the blower motor

runs at 70% CFM until the first−stage demand is satisfied.

OFF

CALL

100%

70%

57%

Y1

7−1/2

minutes

60

sec

y2/Y1

Y1 − 1st−stage COOL Demand Present

y1 − 1st−stage COOL Demand Satisfied

Y2 − 2nd−stage COOL Demand Present

y2 − 2nd−stage COOL Demand Satisfied

Y1/Y2

70%

57%

y1

y1

OFF

60

sec

If first−stage cooling does not satisfy the demand, the ther-

mostat calls for 2nd-stage cooling, closing the R to Y2 cir-

cuit on the A54 blower control board. The blower motor

ramps up to 100% CFM.

When the Y2 demand is met, the blower ramps down to Y1

at 70% CFM until Y1 is met, and ramps down to 57% CFM

for 1 minute, then turns off.

HEAT

The unit is factory−set to run at the middle of heating rise

range as shown on the unit rating plate. The jumper on the

tap marked

HEAT

should remain in the position (A, B, D, or

D) as shown in the HEATING SPEED SELECTOR PINS

graphic found in the wiring diagram (figure 18).

The

HEAT

jumper is used to determine CFM during gas

heat operation only. These jumper selections are activated

only when W1 is energized.

During the heat ON delay, the blower runs at 13% CFM for

the first minute, 50% CFM for the second minute, and full

CFM after two minutes.

OFF

CALL

100%

82%

50%

13%

W

60

sec

60

sec

210 seconds

w

W − Heat Demand Present

w − Heat Demand Satisfied

When the demand for heat is met, the blower ramps down

to 82% CFM for 3−1/2 minutes, then turns off.

Heat Pump

IMPORTANT

For heat pump operation, cut the jumper between R

and O near the R terminal of A54 and connect the

pigtail to the thermostat O wire (A54 board O" to

thermostat O"). See figure 18 wiring diagram.

In heat pump mode, a call for heat pump operation follows

the same sequence as a call for cooling, with the exception

that there is a 30−second blower ramp−up to blower CFM.

Downloaded from