Page 18

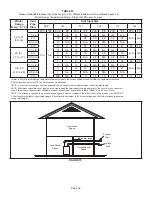

TABLE 8

Problem

Corrective Action

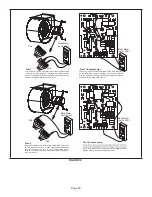

Pressure switch stuck closed

Check that the pressure switch is open without the com

-

bustion air inducer operating. Replace if defective.

Pressure switch does not close due to obstruction in vent

pipe.

Check for restricted vent. Remove all blockage. Check for

proper vent sizing. See table 13.

Pressure switch does not close due to incorrect routing of

the pressure switch tubing.

Check that the pressure switch tubing is correctly routed.

Correctly route pressure witch line.

Pressure switch does not close due to obstructions in the

pressure switch line.

Remove any obstructions from the the pressure switch

line and/or taps

Pressure switch tubing damaged.

Check pressure switch tubing for leaks. Replace damaged

tubing if necessary.

Condensate in pressure switch tubing.

Check pressure switch tubing for condensate. Remove

condensate from tubing.

Pressure switch does not close due to a low differential

pressure across the pressure switch.

Check the differential pressure across the pressure

switch. Check for restricted inlet vent. Remove all block

-

age. Check for proper vent sizing and run length. See

table 13.

Wrong pressure switch installed in the unit, or pressure

switch is out of calibration

Check that the correct pressure switch is installed in the

unit. Replace pressure switch if necessary.

Miswiring of furnace or improper connections at pressure

switch.

Check for correct wiring and loose connections. Correct

wiring and/or replace any loose connections.

Pressure switch failure.

If all the above modes of failure have been checked, the

pressure switch may have failed. Replace pressure switch

and determine if unit will operate.

Damaged condensate trap.

Check trap for any cracks or damage and replace if nec

-

essary.

Cold end header box does not drain properly.

Check that the furnace is set properly with a slight tilt (0

- 1/2”) towards the front if necessary. See furnace installa

-

tion instruction.

Air leakage around the combustion air inducer gasket.

Check gasket and replace if necessary.

Air leakage around the cold end header box gasket.

Check gasket and replace if necessary.

Damaged cold end header box tubing.

Check tubing and replace if necessary.

Содержание ML196UH030XE36B

Страница 57: ...Page 57...