Page 1

©

2003 Lennox Industries Inc.

Corp. 0304−L4

G50UHi

Service Literature

Revised 10−2005

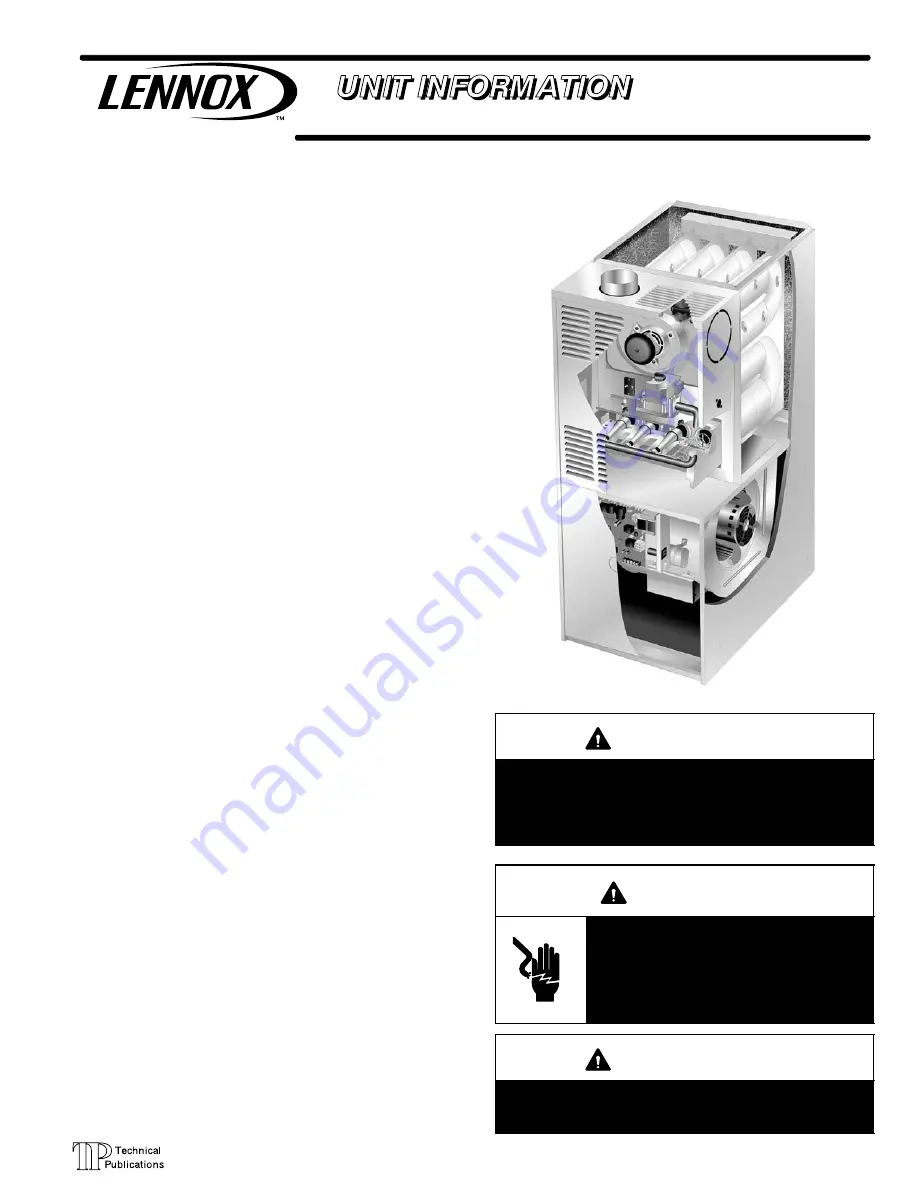

G50UHi Series Units

G50UHi series units are mid−efficiency gas furnaces used

for upflow or horizontal applications only, manufactured

with Lennox Duralok Plus

®

heat exchangers formed of alu-

minized steel. G50UHi units are available in heating capac-

ities of 66,000 to 154,000 Btuh and cooling applications up

to 5 tons. Refer to Engineering Handbook for proper sizing.

Units are factory equipped for use with natural gas. Kits are

available for conversion to LPG operation. G50UHi model

units are equipped with the Lennox SureLight

®

silicon ni-

tride ignition system and blower control module. The blower

control module allows the G50Ui to maintain a constant

CFM over a wide range of operating static pressure. All units

use a redundant gas valve to assure safety shut−off as re-

quired by C.S.A.

All specifications in this manual are subject to change. Pro-

cedures outlined in this manual are presented as a recom-

mendation only and do not supersede or replace local or

state codes. In the absence of local or state codes, the

guidelines and procedures outlined in this manual (except

where noted) are recommended only and do not constitute

code.

TABLE OF CONTENTS

Introduction

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High Altitude

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blower Data

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Identification

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I Unit Components

8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II Installation

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III Start Up

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV Heating System Service Checks

17

. . . . . . . . . . . . . .

V Typical Operating Characteristics

20

. . . . . . . . . . . . . .

VI Maintenance

20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VII Wiring and Sequence of Operation

22

. . . . . . . . . . . .

VIII Troubleshooting

28

. . . . . . . . . . . . . . . . . . . . . . . . . . .

IMPORTANT

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, person-

al injury or loss of life. Installation and service must

be performed by a qualified installer, service agency

or the gas supplier.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at discon-

nect switch(es). Unit may have multiple

power supplies.

WARNING

Sharp edges.

Be careful when servicing unit to avoid sharp edges

which may result in personal injury.

Содержание G50UHi Series

Страница 6: ...Page 6 FIGURE 1...

Страница 22: ...Page 22 VII WIRING AND SEQUENCE OF OPERATION...