23

22

3

22B

22A

22

22A

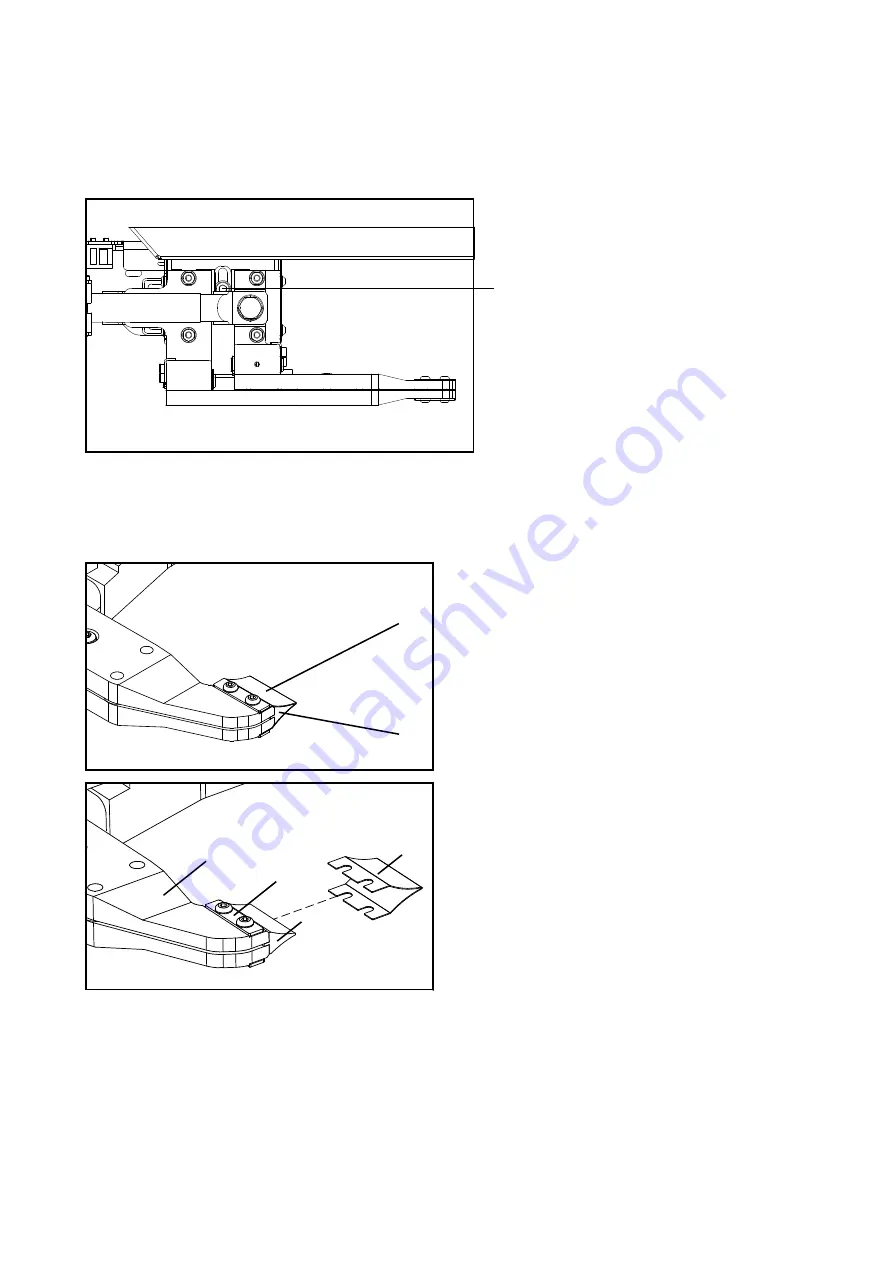

2C

Slight differences in height are automatically adjusted by the bracket fixture. Nevertheless, the height of the hot wedge

must be checked and – if necessary – adjusted every time the wedge holder is changed. Locking screw 2C can be

used to adjust the height of the wedge holder/wedge. Loosen the screw slightly while holding on to the holder. Adjust

the height of the holder so that the tip of the hot wedge is precisely in the middle of the two closed welding wheels.

Then firmly re-tighten the screw. Carry out this step in the swiveled-in position but make sure that the wedge is not in

contact with the wheels.

Always use the wedge change wizard (Chapter 9.6) when changing the wedge. This significantly reduces the risk of

injury and collisions and minimizes potential errors. Always ensure that the heating is switched off before changing

the wedge.

The hot-wedge plate is fastened in place with four screws.

Loosen the screws slightly and remove the hot wedge (22)/

the hot-wedge plate. Then check the filler piece (22A) for

possible damage. The filler piece holds the wedge in the right

shape during the welding process and protects the wedge

from mechanical damage. If it is damaged, carefully replace

the filler piece.

Push the new hot wedge (22) on to the holder. Lift the upper

metal plate slightly so the wedge comes to rest between the

holder (3) and the pressure plate (22B). Now use a finger to

push the hot wedge as far as it will go and then tighten all

four screws.

Now carry out the wedge adjustment program (Chapter 9.6).

Remove the upper and lower pressure plates (22B) at regular

intervals and clean the wedge contact surfaces on the pres-

sure plate (22B) and the holder (3).

8.4 Adjusting the Welding Wedge Height

8.5 Changing the Wedge