Installation Instructions

TILD1X05US / TILD1X1US / TILD1X2US / TILVAB2

9

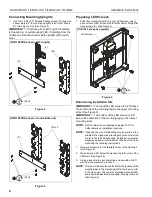

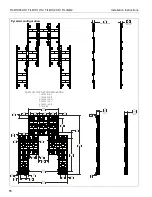

8.

Slide the left (A-Left) and right (A-Right) adjustment washers

into place behind the partially installed lag screws. (See

Figure 12)

Figure 12

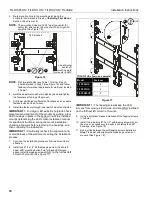

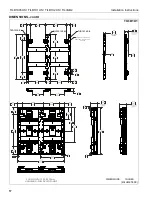

9.

Check the level of the mount at the bottom of the teardrop

slots. (See Figure 13)

10. If the mount is not level, slide or use a dead blow hammer

to lightly tap the spacer into place. This will lift the mount up

as the lag screw rides in the washer’s angled slot. (See

Figure 13)

11. When the mount is leveled, tighten the lag screws (C). (See

Figure 13)

Figure 13

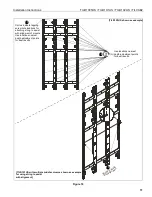

12. Drill pilot holes in centerline of lower slots (see Table 1 for

size) and follow fastener information (appropriate for wall

type) located in Table 1. (See Figure 14)

13. Double check the level of the mount along the side of the

mount. (See Figure 14)

14. Fully tighten the 5/16 x 2-1/2" lag screws (C) through the 5/16"

fender washers (D). (See Figure 14)

Figure 14

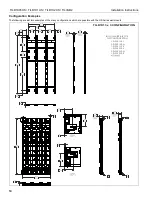

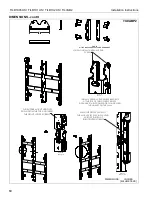

Adding Additional Uprights

1.

Use four 10-24 x 1/2" flathead Phillips screws (Q) to secure

spacer plates (P) to mounting uprights (M and M or N). (See

Figure 15)

NOTE:

Add uprights (M or N) one by one from left to right as

the mounting system is being built on the wall.

Figure 15

2.

Lay levels across flat of the mounting holes and center-of-

screen indicators, and vertically along side of mount to

ensure wall mount is square and level.

NOTE:

Lift up slightly on the far side of the second mount to help

level the mount.

8

A (right)

A (left)

Just a tip -

Tighten down the lag screw on the

side that does

NOT

need to be raised. This

creates a pivot point for when the opposite

adjustment washer is tapped into place, and

allows that correct side of the mount to move up.

Level

Dead blow

hammer

11

(C) x 2

9

10

14

(C) x 2

12

x 2

13

Level

(D) x 2

1

(Q) x 4

(P)

(L)

(M)

(M or N)

(TILD1X2US shown)