10

DALì

English

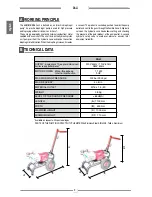

I2

I1

I3

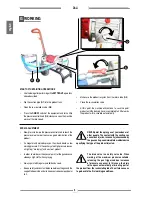

CLEANING THE COMPRESSION VALVE

When the compression valve (

I3

) must be removed, clean it with

specific solvents depending on the type of paint used and refit all

parts by inverting the removal order.

Assemble the components in the correct

order.

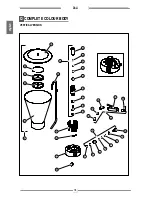

REPLACING HYDRAULIC OIL

After operating for 100 hours, replace the oil in the pump;

•

Discharge the waste oil through the

plug

(

I4

) fitted at the

bottom of the pump casing.

•

Clean the seals on the cap and replace it if worn.

•

Remove and clean the filter (

I5

) on the side of the pump

casing; if necessary, replace the filter and the respective

seals.

•

Clean and, if necessary, replace the worn seals

(

I5

).

•

Replace the plug

(

I4

).

•

Fill the pump with the recommended oil until it reaches the

maximum level.

•

Then, substitute the oil every 250 hours.

I

ROUTINE MAINTENANCE

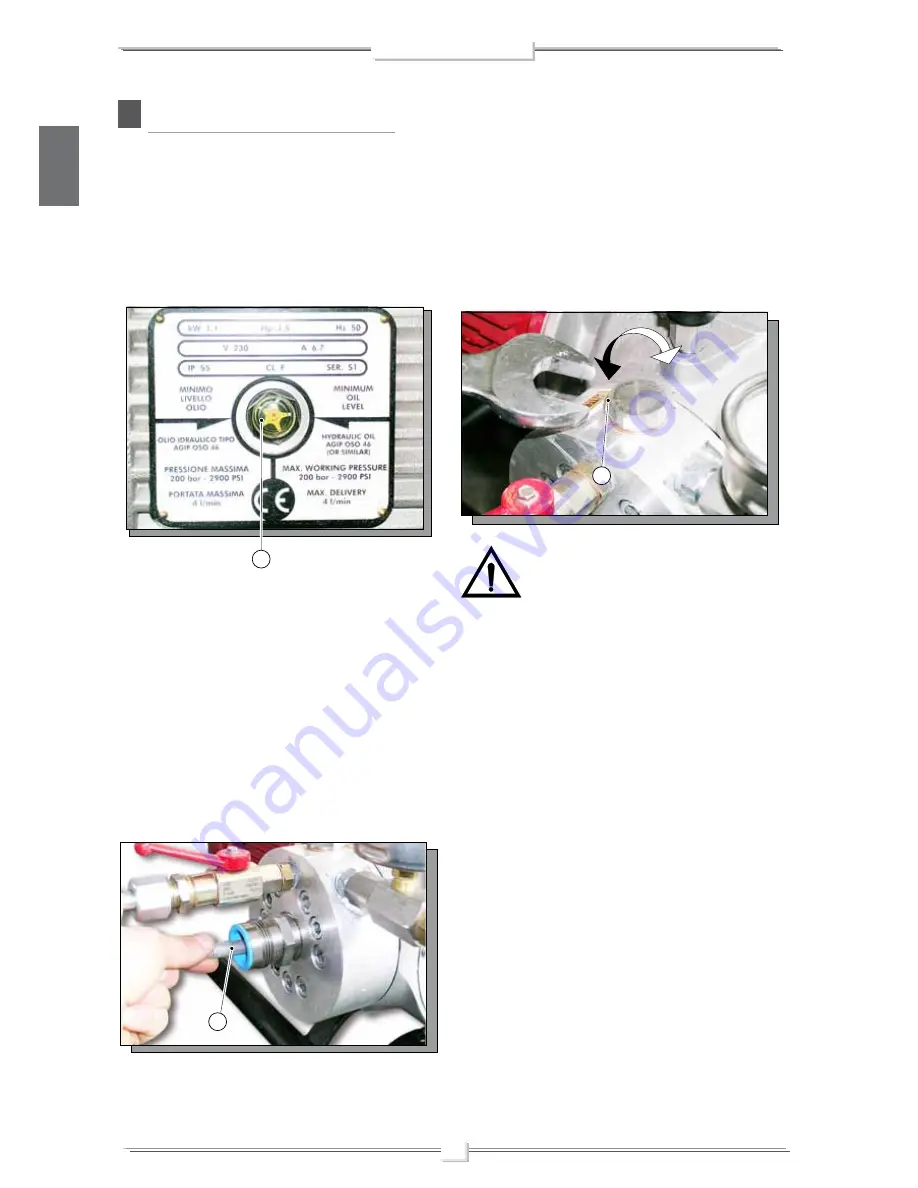

TOP UP HYDRAULIC OIL

With each start up, check the hydraulic oil level by looking through

the gauge (

I1

) on the side of the hydraulic body. If necessary, use

“AGIP OSO 46 type hydraulic oil”

to top up the level.

RELEASE THE SUCTION VALVE

If the pump malfunctions, release the suction valve fitted on the

head of the pump in the following way:

•

Remove the suction hose fitting and release the valve by

inserting a rigid rod (

I2

) with a diameter of no more than 15

mm.