8

DALì

English

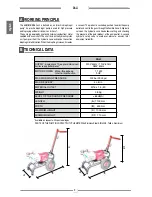

G2

G3

G1

G4

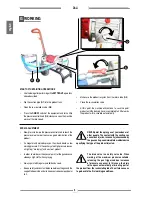

NEVER point the spray gun at yourselves or at

other people. The contact with the casting can

use serious injuries. In case of injuries caused by

the gun casting, seek immediate medical advice

specifying the type of the product injected.

The drain valve is a safety valve too. When

working at the maximum pressure available,

releasing the gun trigger sudden increases

of pressure can occur. In this case, the drain

valve opens automatically eliminating part of

the product from the recirculating tube. Then it closes so as

to go back to the first working conditions.

G

WORKING

START OF THE PAINTING OPERATIONS

• Use the tooling after performing all the

SETTING UP

operations

above described.

• Dip the suction pipe (

G1

) into the product tank.

•

Open the re-circulation valve (

G2

).

•

Press the

ON/OFF

switch of the equipment and turn a little

the pressure control knob (

G3

) clockwise, so as the machine

works at the idle speed.

SPRAY ADJUSTMENT

•

Slowly turn clockwise the pressure control knob to reach the

pressure value in order to ensure a good atomization of the

product.

•

An irregular and marked spray on the sides indicates a low

working pressure. On the contrary, a too high pressure causes

a high fog (

“overspray”

) and waste of product.

•

In order to avoid overthickness of paint, let the gun advance

sideways (

right-left

) when spraying.

•

Always paint with regular parallel bands coats.

•

Keep a safety and constant distance between the gun and the

support to be painted and also keep yourselves perpendicular

to it.

•

Make sure the product recycles from the return tube (

G4

).

•

Close the re-circulation valve.

•

At this point the machine will continue to suck the paint

product until the delivery hose is completely full. Afterwards,

the product will re-circulate automatically.