2-3

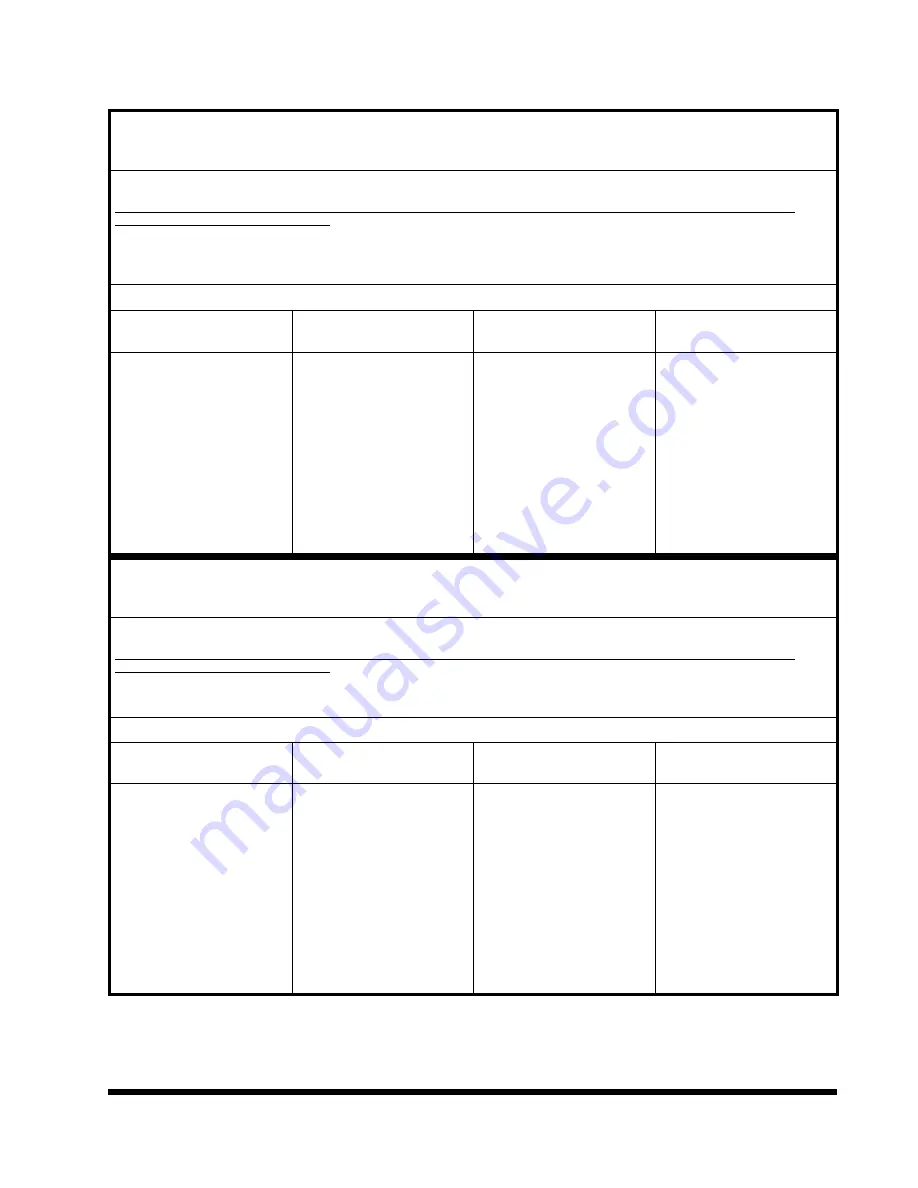

LANDOLL CORPORATION

HYDRAULIC FITTING TORQUE SPECIFICATIONS

37

o

JIC, ORS, & ORB (REV. 10/97)

THIS CHART PROVIDES TIGHTENING TORQUES FOR HYDRAULIC FITTING APPLICATIONS WHEN SPECIAL TORQUES ARE NOT SPECIFIED

ON PROCESS OR DRAWING.

ASSEMBLY TORQUES APPLY TO PLATED CARBON STEEL AND STAINLESS STEEL FITTINGS ASSEMBLED WITHOUT SUPPLEMENTAL

LUBRICATION (AS RECEIVED CONDITION)

.

THEY DO NOT APPLY IF SPECIAL GRAPHITE MOLY-DISULFIDE OR OTHER EXTREME

PRESSURE LUBRICANTS ARE USED.

BRASS FITTINGS AND ADAPTERS - 65% OF THE TORQUE VALUE FOR STEEL. STAINLESS STEEL, ALUMINUM AND MONEL - THREADS ARE

TO BE LUBRICATED.

TORQUE IS SPECIFIED IN FOOT POUNDS

PARKER BRAND FITTINGS

Dash

Size

37 Degree

JIC

O-Ring

(ORS)

O-Ring Boss

(ORB)

-4

11-13

15-17

13-15

-5

14-16

21-23

-6

20-22

34-36

25-29

-8

43-47

58-62

40-44

-10

55-65

100-110

57.5-62.5

-12

80-90

134-146

75-85

-16

115-125

202-218

109-121

-20

160-180

248-272

213-237

-24

185-215

303-327

238-262

-32

250-290

310-340

LANDOLL CORPORATION

HYDRAULIC FITTING TORQUE SPECIFICATIONS

37

o

JIC, ORS & ORB (REV. 10/97)

THIS CHART PROVIDES TIGHTENING TORQUES FOR HYDRAULIC FITTING APPLICATIONS WHEN SPECIAL TORQUES ARE NOT SPECIFIED

ON PROCESS OR DRAWING.

ASSEMBLY TORQUES APPLY TO PLATED CARBON STEEL AND STAINLESS STEEL FITTINGS ASSEMBLED WITHOUT SUPPLEMENTAL

LUBRICATION (AS RECEIVED CONDITION)

.

THEY DO NOT APPLY IF SPECIAL GRAPHITE MOLY-DISULFIDE OR OTHER EXTREME

PRESSURE LUBRICANTS ARE USED.

BRASS FITTINGS AND ADAPTERS - 65% OF THE TORQUE VALUE FOR STEEL.

TORQUE IS SPECIFIED IN FOOT POUNDS.

AEROQUIP BRAND FITTINGS

Dash

Size

37 Degree

JIC

O-Ring

(ORS)

O-Ring Boss

(ORB)

-4

11-12

10-12

14-16

-5

15-16

18-20

-6

18-20

18-20

24-26

-8

38-42

32-35

50-60

-10

57-62

46-50

72-80

-12

79-87

65-70

125-135

-14

160-180

-16

108-113

92-100

200-220

-20

127-133

125-140

210-280

-24

158-167

150-165

270-360

-32

245-258

Table 2-2 Hydraulic Fitting Torque Specifications

Содержание 876 Series

Страница 3: ...MODEL 876 WING SERIES TILLOLL OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO i...

Страница 4: ...ii...

Страница 8: ......

Страница 12: ...2 4 Figure 2 1 876 30 Shank Placement Assembly 1 of 2...

Страница 13: ...2 5 Figure 2 2 876 30 Shank Placement Assembly 2 of 2...

Страница 14: ...2 6 Figure 2 3 876 35 Shank Placement Assembly 1 of 2...

Страница 15: ...2 7 Figure 2 4 876 35 Shank Placement Assembly 2 of 2...

Страница 16: ...2 8 Figure 2 5 876 40 Shank Placement Assembly 1 of 2...

Страница 17: ...2 9 Figure 2 6 876 40 Shank Placement Assembly 2 of 2...

Страница 18: ...NOTES 2 10...

Страница 20: ...3 2 Figure 3 1 Frame Wing and Extension Assembly...

Страница 21: ...3 3 Figure 3 2 Frame Wing and Extension Assembly...

Страница 22: ...3 4 Figure 3 3 Frame Wing and Extension Assembly...

Страница 24: ...3 6 Figure 3 4 Shank Clamp and Sweep Assembly...

Страница 26: ...3 8 Figure 3 5 Hydraulic Lift Assembly...

Страница 28: ...3 10 Figure 3 6 Hydraulic Fold Assembly...

Страница 30: ...3 12 Figure 3 7 Disc Gang and Spray Shield Installation...

Страница 32: ...3 14 Figure 3 8 Reel Assembly Installation...

Страница 34: ...3 16 Figure 3 9 Harrow Assembly Installation...

Страница 36: ...3 18 Figure 3 10 Pull Hitch Installation...

Страница 38: ...3 20 Figure 3 11 Electrical Installation...

Страница 40: ...3 22 Figure 3 12 Decal Installation...

Страница 42: ...NOTES 3 24...

Страница 53: ...NOTES 4 11...

Страница 54: ......

Страница 58: ...NOTES 5 4...