OPERATION AND MAINTENANCE

4-15

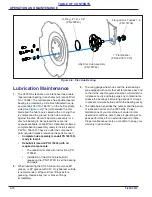

Figure 4-9: Lubrication Schedule

Rubber Roller Scraper

Adjustment

The roller scrapers should be adjusted so that they have

an adequate clearance from the rubber roller grooves but

not excessive

(

If the clearance exceeds a

1/4 inch, plugging may occur. 5/32 to 1/4” clearance is

optimum.

•

The rubber rollers are subject to some irregularity in

diameter, especially during initial use or when

returning to duty after have set for a period.

•

It is always a good idea to rotate the rubber rollers

after making adjustments to assure an adequate

clearance between the roller and the scrapers.

•

The scrappers will require adjustment periodically as

they wear to maintain the proper clearance.

Lubrication Table

ITEM

DESCRIPTION

NO. OF LUBE POINTS

INTERVAL

(Hours Unless Stated)

1

Reel Bearings

2 per Reel Section

10

2

Wing Wheel Hubs

1 each

50

3

Center Section Wheel Hubs

(2) Check and Re-pack

250-500

4

Center Section/Hitch Pivot

2 each

10

5

Center Section/Wing Frame Fold (FRONT)

2 each

10

Center Section/Wing Frame Fold (REAR)

2 each

10

6

Main Tilt Cylinder

2 each

50

2

1

6

2

6

5

4

3

5