PAGE 28

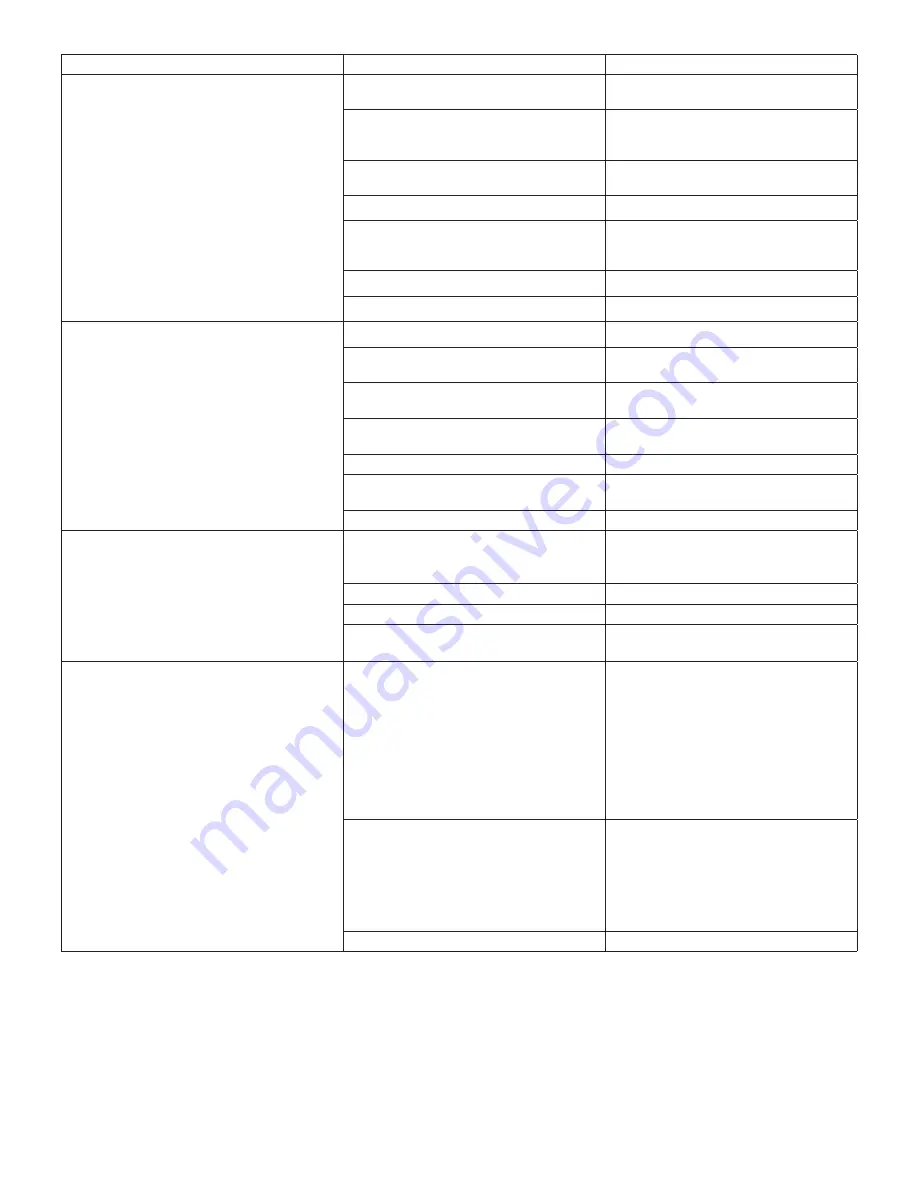

Problem

Possible Cause

Solution

7. Control valve does not backwash

automatically but

does

when the

REGEN

button

is depressed and held.

a. Bypass valve in bypass position optional

a. Turn bypass handles to place bypass in

service position

b. Meter is not connected to meter

connection on PC Board if meter is

installed

b. Connect meter to three pin connection

labeled METER on PC Board

c. Restricted/ stalled meter turbine if meter is

installed

c. Remove meter and check for rotation or

foreign material

d. Incorrect programming

d. Check for programming error

e. Meter wire not installed securely into three

pin connector if meter is installed

e. Verify meter cable wires are installed

securely into three pin connector

labeled METER

f. Defective meter if installed

f. Replace meter

g. Defective PC Board

g. Replace PC Board

8. Untreated water is being delivered

a. Bypass valve is open or faulty

a. Fully close bypass valve or replace

b. Media is exhausted due to high water

usage

b. Check program settings or diagnostics

for abnormal water usage

c. Meter not registering if installed

c. Remove meter and check for rotation or

foreign material

d. Water quality fluctuation

d. Test water and adjust program values

accordingly

e. Damaged seal/stack assembly

e. Replace seal/stack assembly

f. Control valve body type and piston type

mix matched

f. Verify proper control valve body type

and piston type match

g. Fouled media bed

g. Replace media bed

9. Water running to drain

a. Power outage during regeneration

a. Upon power being restored control

will finish the remaining regeneration

time. Reset time of day

b. Damaged seal/ stack assembly

b. Replace seal/ stack assembly

c. Piston assembly failure

c. Replace piston assembly

d. Drive cap assembly not tightened in

properly

d. Re-tighten the drive cap assembly

10. Error – 101 = Control unable to sense motor

movement

a. Motor not inserted full to engage pinion,

motor wires broken or disconnected

a. Disconnect power, make sure motor is

fully engaged, check for broken wires,

make sure two pin connector on motor

is connected to the two pin connection

on the PC Board labeled MOTOR.

Press

NEXT

and

REGEN

buttons for

3 seconds to resynchronize software

with piston position or disconnect

power supply from PC Board for 5

seconds and then reconnect.

b. PC Board not properly snapped into drive

bracket

b. Properly snap PC Board into drive

bracket and then Press

NEXT

and

REGEN

buttons for 3 seconds to

resynchronize software with piston

position or disconnect power supply

from PC Board for 5 seconds and then

reconnect.

c. Missing reduction gears

c. Replace missing gears

Содержание X FACTOR LX15 Series

Страница 31: ...PAGE 31 NOTES ...