29

EN

cod. 3540S420 - 05/2010 (Rev. 00)

EN

1. GENERAL INSTRUCTIONS

•

Carefully read the instructions contained in this instruction booklet.

•

After boiler installation, inform the user regarding its operation and give him this manual, which is an integral

and essential part of the product and must be kept with care for future reference.

•

Installation and maintenance must be carried out by professionally qualified personnel, according to current

regulations and the manufacturer's instructions. Do not carry out any operation on the sealed control parts.

•

Incorrect installation or inadequate maintenance can result in damage or injury. The Manufacturer declines

any liability for damage due to errors in installation and use or failure to follow the instructions.

•

Before carrying out any cleaning or maintenance operation, disconnect the unit from the power supply using

the system switch and/or the special cut-off devices.

•

In case of a fault and/or poor operation, deactivate the unit and do not attempt to repair it or directly intervene.

Contact professionally qualified personnel. Repair/replacement of the products must only be carried out by

professionally qualified using original spare parts. Failure to comply with the above could affect the safety of

the unit.

•

This unit must only be used for its intended purpose. Any other use is considered improper and therefore

dangerous.

•

The packing materials are potentially hazardous and must not be left within the reach of children.

•

The images given in this manual are a simplified representation of the product. In this representation there

may be slight and insignificant differences with respect to the product supplied.

2. OPERATING INSTRUCTIONS

2.1 Introduction

Dear Customer,

Thank you for choosing

PEGASUS 56

, a floor-standing boiler

FERROLI

featuring advanced de-

sign, cutting-edge technology, high reliability and quality construction. Please read this manual

carefully and keep it for future reference.

PEGASUS 56

is a high-efficiency heat generator for central heating using natural gas or liquefied

gas (configurable at the time of installation) and regulated by an advanced electronic control sys-

tem.

The boiler shell consists of cast-iron elements whose particular shape guarantees high exchange

efficiency under all operating conditions and an open-flue burner equipped with electronic ignition

and ionization flame control.

The boiler is also equipped with a

temperature limiter

(safety thermostat) and

a fume evacuation

control device

(fume thermostat).

Thanks to the electronic flame control and ignition system, boiler operation is mostly automatic.

The user only has to set the temperature required inside the home (by means of the optional room

thermostat, whose installation is recommended) or adjust the temperature of the system.

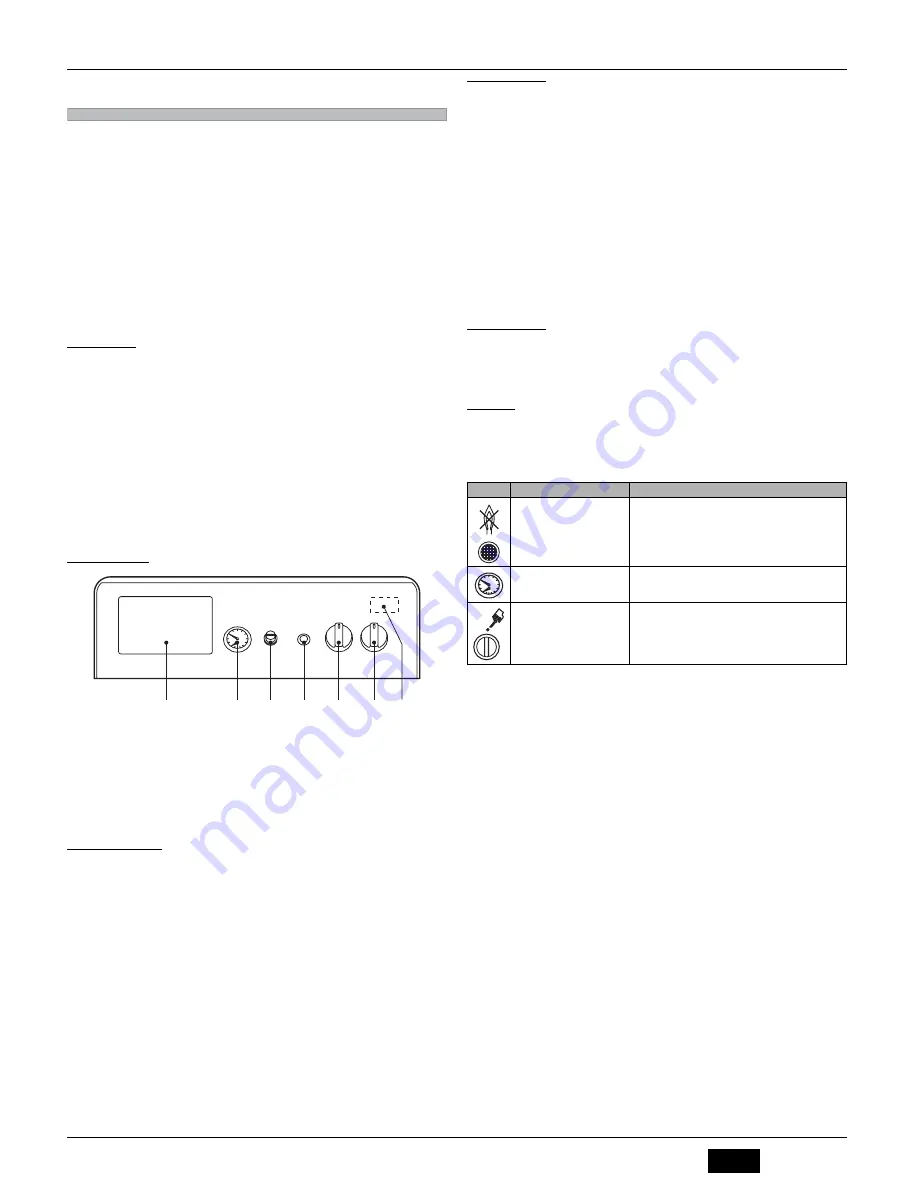

2.2 Control panel

fig. 1 - Control panel

Key

1

Arrangement for Thermostatic Controller

2

Boiler pressure/temperature gauge

3

Fume thermostat cover

4

Flame controller reset button with shutdown light

5

Boiler control thermostat

6

0-1-Test switch

7

Automatic reset safety thermostat (located inside the panel)

2.3 Turning on and off

Lighting

•

Open the gas cock ahead of the boiler

•

Turn on the switch or insert the plug (if present) ahead of the boiler

•

Turn the main switch

“6”

to position

1

(fig. 1).

•

Turn the knob

“5”

to the selected temperature and that of the room thermostat (if present) to

the required temperature value. The burner will light and the boiler begins to function auto-

matically, controlled by its adjustment and safety devices.

•

If the boiler is equipped with an electronic thermostatic controller fitted in position

1

of fig. 1,

the user must also take into account the manufacturer's instructions.

A

If the burners do not light and the pushbutton-shutdown indicator

4

comes on after cor-

rectly carrying out the lighting procedures, wait about 15 seconds and then press the

above pushbutton. The reset controller will repeat the lighting cycle. If the burners do not

light even after several attempts, contact an authorised service centre or qualified per-

sonnel.

Turning off

Close the gas cock ahead of the boiler, turn knob

“6”

to 0 and disconnect the power to the unit.

B

To avoid damage caused by freezing during long idle periods in winter, it is advisable to

drain all water from the boiler and system; or add a suitable antifreeze to the heating sys-

tem.

The boiler switch

6

has 3 positions “0-1-TEST”; the first two have the on-off function, the

third (unstable) must only be used for service and maintenance purposes.

2.4 Adjustments

System temperature adjustment

Turn the knob

5

of fig. 1 clockwise to increase the heating water temperature, or anti-

clockwise to decrease the temperature. The temperature can be varied from a minimum

of 30°C to a maximum of 90°C. However, it is advisable not to operate the boiler below

45°C.

Room temperature adjustment (with optional room thermostat)

Using the room thermostat, set the required room temperature. Controlled by the room

thermostat, the boiler lights and brings the system water to the temperature set by boiler

control thermostat

5

of fig. 1. The generator turns off when the required temperature in

the rooms is reached.

If the room thermostat is not present, the boiler will keep the system at the temperature

set by the boiler control thermostat.

Water system pressure adjustment

The filling pressure with system cold, read on the boiler water gauge detail

2

of fig. 1,

must be approx. 1.0 bar. If, during operation, the system pressure falls (due to the evap-

oration of gases dissolved in the water) to values below the minimum described above,

the User must bring it to the initial value by operating the filling cock. At the end of the

operation always close the filling cock.

2.5 Maintenance

The user must have the heating system serviced by qualified personnel at least once a

year and combustion checked at least every two years. Consult sec. 4.3 of this manual

for more information.

The boiler casing, panel and aesthetic parts can be cleaned with a damp soft cloth, if nec-

essary soaked in soapy water. Do not use abrasive detergents and solvents.

2.6 Faults

Given below are the faults that can be caused by simple, user-solvable problems.

A

Before calling the after-sales service, check that the problem is not due to no

gas or power.

1

2

3

4

5

6 7

Symbol

Fault

Cure

Boiler shutdown by the flame con-

troller

Make sure the gas cocks ahead of the boiler and on the meter are

open.

Press the lit pushbutton-indicator.

In case of repeated boiler shutdowns, contact the nearest after-

sales service centre.

Boiler shutdown due to insufficient

system pressure (only if a water

pressure switch is installed)

Fill the system to 1-1.5 bar cold by means of the system filling

cock.

Close the cock after use.

Boiler shutdown due to insufficient

evacuation of fumes

Unscrew the fume thermostat cover and press the button below.

In case of repeated boiler shutdowns, contact the nearest after-

sales service centre.

Содержание GASTER N 56 AW

Страница 10: ......

Страница 19: ......

Страница 28: ......

Страница 49: ...49 RU cod 3540S420 05 2010 Rev 00 1 2 3 4 5 6 7 8 4 4 1 fig 10 3 3 4 mm 5 4 8 10 40 C...

Страница 51: ...51 RU cod 3540S420 05 2010 Rev 00 5 5 14 24 32 44 49 63 72 82 83 92 98 129 159 160 A...

Страница 52: ...52 RU cod 3540S420 05 2010 Rev 00 15 24 32 44 49 63 72 82 83 92 98 129 159 160 A...

Страница 59: ...59 UK cod 3540S420 05 2010 Rev 00 5 5 i 14 24 32 44 49 63 72 i 82 83 92 98 129 i 159 160 i A i i i...

Страница 60: ...60 UK cod 3540S420 05 2010 Rev 00 15 i 24 32 44 49 63 72 i 82 83 92 98 129 i 159 160 i A i i i i...

Страница 63: ......