13

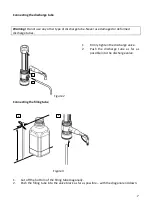

Preparation prior to the autoclaving

Figure 14

Figure15

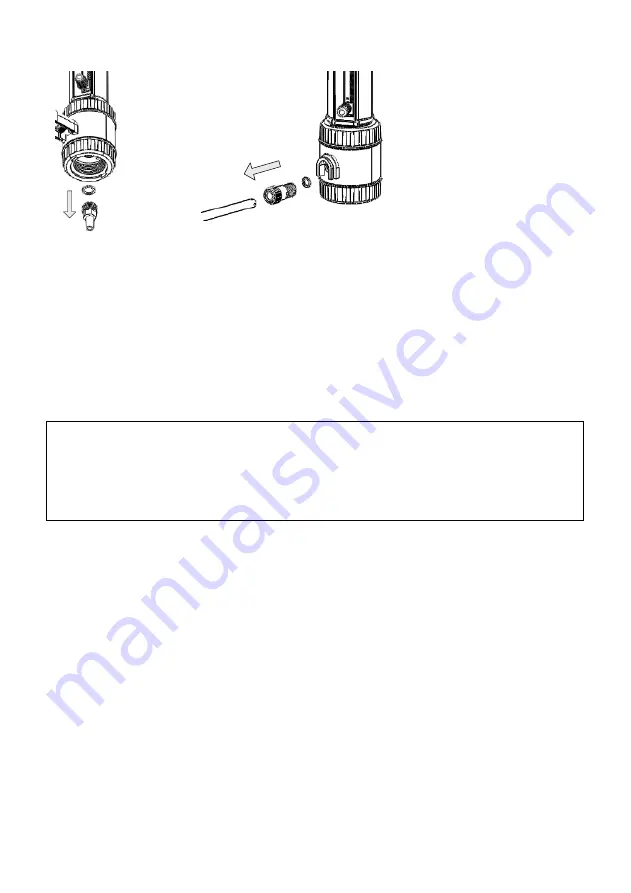

Unscrew filling valve (13) and discharge valve (8).

Replace built-in PTFE-rings (12) with the supplied elastic O-rings.

Screw in the filling valve (13) and discharge valve (8) and tighten them firmly using

the mounting tool.

1.

Clean the instrument before sterilization.

2.

Remove the discharge tube (10) with removed closure cap (11), filling tube (14), and

put all parts on a towel. Avoid contact with hot metal surfaces.

3.

Lay the instrument with piston in down position

on the towel.

4.

Autoclave all parts.

Note:

Allow to cool down in the closed autoclave to avoid deformation through too rapid cooling.

After every autoclaving, inspect all parts for deformities or damage. If necessary, replace them.

Do not reassemble the instrument until it has cooled down to room temperature (cooling time

approx. 2 hours).

Mounting tool can be steam sterilized at 121 °C.

10.

Checking the Volume

The accuracy and coefficient of variation of the instrument are determined gravimetrically as

follows:

Set to the nominal volume.

Dispense distilled H

2

O.

Weigh the dispensed quantity on an analytical balance.

Calculate the dispensed volume taking the temperature into account.

Perform at least 10 dispensing and weighing operations.

Calculate the accuracy (A%) and the coefficient of variation (CV%) by means of the

formula used in statistical quality control. The proceeding is described e.g., in DIN EN

ISO 8655-6. Observe the operating manual of the balance manufacturer and the

corresponding standards.

Содержание 550.001.305

Страница 16: ...16...