23

The vent system must terminate so that proper clearances are maintained as cited in local codes or the latest

edition of the National Fuel Gas Code, ANSI Z223.1:

1. Do not terminate near soffit vents or crawl space or other area where condensate or vapor could create a

nuisance or hazard or cause property damage.

2. Do not terminate the exhaust vent terminal where condensate or vapor could cause damage or could be

detrimental to the operation of regulators, relief valves, or other equipment.

3. Do not terminate the exhaust vent terminal over public area or walkways where condensate or vapor can

cause nuisance or hazard.

4. The vent shall terminate a minimum of 12 inches above expected snowfall level to prevent blockage of vent

termination.

5. The manufacturer requires the centerline distances between the air intake and exhaust vent terminals to be

a minimum of 36 inches apart and the exhaust terminal must extend 6 inches past the air intake terminal.

Vent pipes serving power vented appliances are classified by building codes as “vent connectors.” Required

clearances from combustible materials must be provided in accordance with information in this manual under

Locating the Water Heater and Clearances, and with National Fuel Gas Code and local codes.

Horizontal Installation

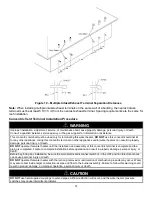

In a horizontal application, it is important that condensate

NOT

be allowed to buildup in the exhaust vent pipe.

To prevent this from happening, the pipe should be installed with a slight upward slope, so the condensate will

run back toward the water heater. The vent system

must

be supported every 5 ft

(1.5 m)

of vertical run and

every 3 ft

(.92 m)

of horizontal run of vent pipe length.

CAUTION

Failure to properly support the vent piping with hangers and clamps may result in damage to the water

heater or venting system.

Stress levels in the pipe and fittings can be significantly increased by improper installation. If rigid pipe clamps

are used to hold the pipe in place, or if the pipe cannot move freely through a wall penetration, the pipe may be

directly stressed, or high thermal stresses may be formed when the pipe heats up and expands. Install

accordingly to minimize such stresses.

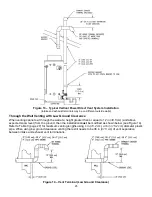

Follow the following procedure for power direct venting through the wall:

1. Cut two 4 ½ in

(11.4 cm)

diameter holes for 4 in (

10.2 cm

) diameter pipe, two 3 ½ in

(8.9 cm)

diameter

holes for 3 in

(7.6 cm)

diameter pipe, or two 6 5/8 in (

16.9 cm

) diameter holes for 6 in (

15.2 cm

) diameter

pipe in the wall. The centerline hole distances

must

be at least 36 in

(91.4 cm)

apart in the location where

the exhaust vent and air intake terminals will exit the outside wall, if vented on the same wall.

2.

Use the proper cement to secure the exhaust vent and air intake terminals provided with the water heater

to the pipes. The distance between the back edge of the exhaust vent terminal and the exterior wall (see

Figure 12) must be 6 in

(15.2 cm)

more for the exhaust vent terminal than the air intake terminal. Use the

proper cement or sealant and assembly procedures to secure the vent connector joints between the

terminal and the blower outlet. Provide support brackets for every 3 ft

(.92 m)

of horizontal vent beyond

the intake terminal.

Clearance to combustibles for all venting pipes and

terminals

For installations in the US

0” minimum

For installations in the CANADA

Refer to vent pipe and terminal

manufacturer’s installation instructions

for clearances to combustibles.

DO NOT

place insulation or other materials in the required clearance spaces between

the venting to combustible material unless otherwise specified.

Содержание LUHE120T

Страница 42: ...42 BMS Wiring Diagram...

Страница 44: ...44 Lighting and Shutdown Instructions Figure 31 Lighting Instruction Label...

Страница 62: ......

Страница 63: ......