Page

30

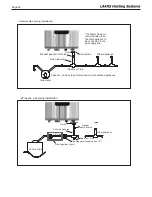

Manifold pres-

sure port.

Offset Fire

Adjustment Screw

Inlet Gas

pressure port

4.10 Gas Supply Pressure

Refer to the illustration. Check the gas inlet pressure

measurement from inlet gas pressure port.(Loosen the

port bolts before you check the gas inlet pressure.)

1. The appliance and its individual shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psi (3.5 kPa).

2. The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psi (3.5 kPa).

Natural Gas

Propane

Maximum

Pressure

10.5˝

WC

Maximum

Pressure

14.0˝

WC

Minimum

Pressure

3.5˝

WC

Minimum

Pressure

8.0˝

WC

Table 10. Min and Max Inlet Gas Line Pressures

Follow these steps.

1.

Establish a call for water by opening a hot water

tap.

2.

Set up your combustion analyzer and place the

sensor in the combustion test port.

3.

Per Table 15 for Max fire, change dip switch 6 to

ON and 7 to OFF. The unit will cycle up to M

ax

fire.

Make sure to draw from at least 2 sinks and 2

showers when performing this verification.

4.

Wait for your combustion analyzer to stabilize

(This may take up to 3 minutes depending on your

analyzer). Then measure your CO2 for

Max fire. Refer to Table 11 for acceptable

M

ax

fire combustion readings. DO NOT

ADJUST CO2 AT MAX FIRE, ONLY AT

MIN FIRE.

5. Change dip switch 6 to OFF and 7 to ON.

The unit will cycle down to MIN fire.

4.11 Gas Setup and Adjustment

Table 11. CO

2

Values

Table 12. Manifold Pressures

WARNING

Installer may be required to verify combustion

settings as part of the installation process.

CO should not exceed 200 PPM. Check local

codes.

Standard Factory Setting is for MIN Fire. 9.0%

CO2 @ 0 - 2,000 ft altitude (Natural Gas).

Continue to next page.

CO

2

Values

Natural Gas (NG) Propane Gas (LP)

2" or 3" VENT

2" or 3" VENT

LT199

(all versions and

all altitudes

)

MAX FIRE

8.5 - 10.5%

9.5 - 11%

MIN FIRE

8 - 10%

9 - 10.5%

Manifold Pressure

LT199

MIN FIRE

+0.07" to +0.13" WC

-0.02" to -0.08" WC

‘

Natural Gas

’ type

combustibility

‘

Propane

’ type

combustibility

Содержание LT Series

Страница 42: ...Page 42 4 20 Wiring Diagram...

Страница 43: ...Page 43 4 21 Ladder Diagram...