2PR

1-4-36

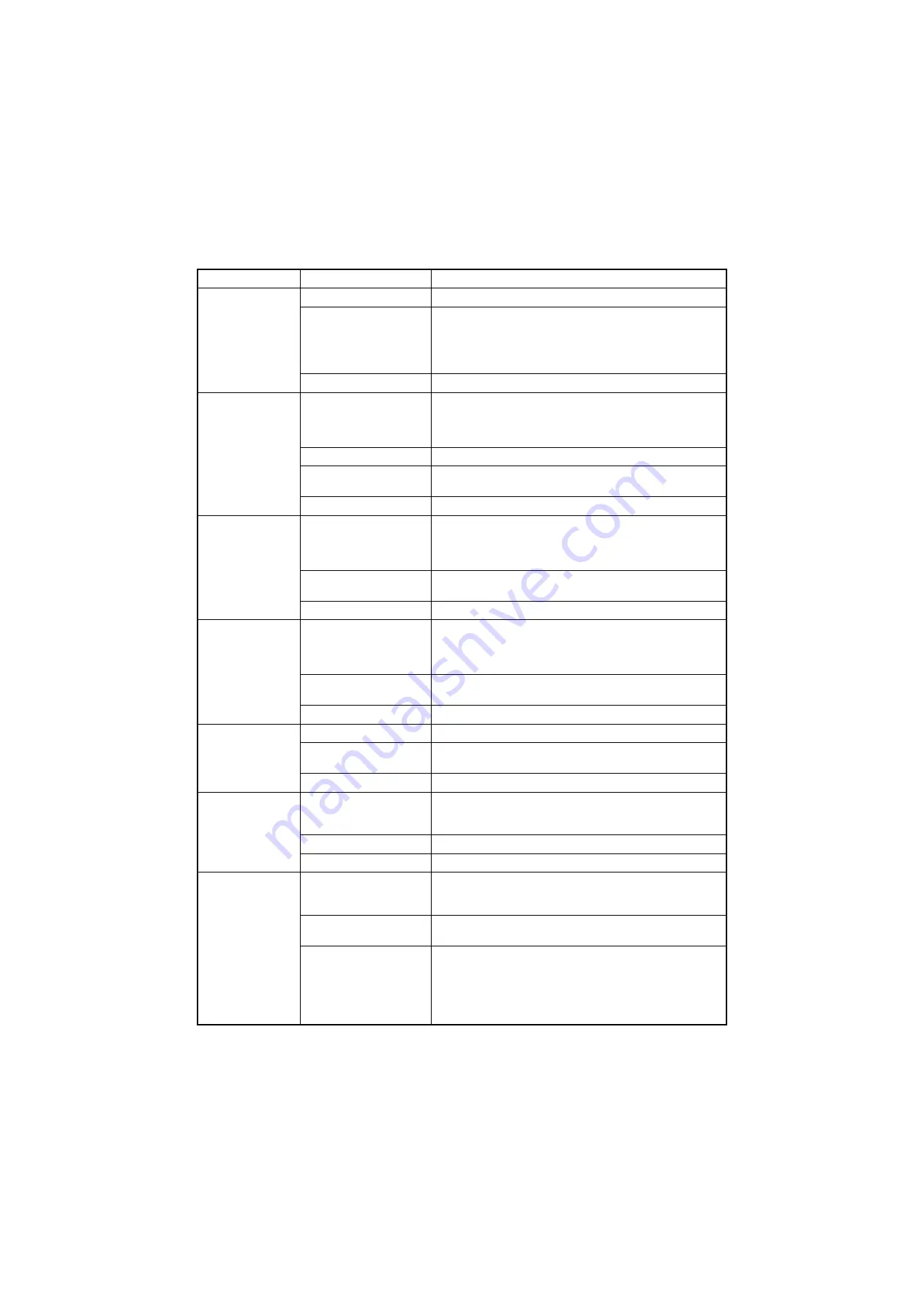

(5)MP paper feed

solenoid, ID solenoid,

duplex solenoid do

not operate.

Broken solenoid coil.

Check for continuity across the coil. If none, replace the solenoid.

Defective harness or

improper connector inser-

tion.

Reinsert the connector. Also check for continuity within the con-

nector harness. If none, remedy or replace the harness.

MP paper feed solenoid - Engine PWB (YC40)

ID solenoid - Engine PWB (YC617)

Duplex solenoid - Engine PWB (YC3)

Defective engine PWB.

Replace the engine PWB (See page 1-5-28).

(6)Main charging is

not performed.

Defective harness or

improper connector inser-

tion.

Reinsert the connector. Also check for continuity within the con-

nector harness. If none, remedy or replace the high voltage PWB

1 (See page 1-5-34).

High voltage PWB 1 - Engine PWB (YC600)

Defective main charger unit Replace the main charger unit (See page 1-5-15).

Defective high voltage PWB

1.

Replace the high voltage PWB 1 (See page 1-5-34).

Defective engine PWB.

Replace the engine PWB (See page 1-5-28).

(7)No developing

bias is output.

Defective harness or

improper connector inser-

tion.

Reinsert the connector. Also check for continuity within the con-

nector harness. If none, remedy or replace the high voltage PWB

1 (See page 1-5-34).

High voltage PWB 1 - Engine PWB (YC600)

Defective high voltage PWB

1.

Replace the high voltage PWB 1 (See page 1-5-34).

Defective engine PWB.

Replace the engine PWB (See page 1-5-28).

(8)Transfer charging

is not performed.

Defective harness or

improper connector inser-

tion.

Reinsert the connector. Also check for continuity within the con-

nector harness. If none, remedy or replace the high voltage PWB

2 (See page 1-5-41).

High voltage PWB 2 - Engine PWB (YC610)

Defective high voltage PWB

2.

Replace the high voltage PWB 2 (See page 1-5-41).

Defective engine PWB.

Replace the engine PWB (See page 1-5-28).

(9)The message

requesting paper to

be loaded is shown

when paper is pres-

ent in the cassette.

Defective paper sensor 1/2. Replace the engine PWB (See page 1-5-28).

Broken paper sensor 1/2

actuator.

Check the bending of the actuator lever of the paper sensor 1/2 if

there is trouble, remedy or replace.

Defective engine PWB.

Replace the engine PWB (See page 1-5-28).

(10)The message

requesting paper to

be loaded is shown

when paper is pres-

ent in the MP tray.

Defective harness or

improper connector inser-

tion.

Reinsert the connector. Also check for continuity within the con-

nector harness. If none, remedy or replace the harness.

MP tray sensor - Engine PWB (YC21)

Defective MP tray sensor.

Replace the MP tray sensor.

Defective engine PWB.

Replace the engine PWB (See page 1-5-28).

(11)The size of paper

in the cassette is not

displayed correctly.

Defective harness or

improper connector inser-

tion.

Reinsert the connector. Also check for continuity within the con-

nector harness. If none, remedy or replace the harness.

Cassette size switch - Engine PWB (YC9)

Defective cassette size

switch.

Replace the cassette size switch.

Defective engine PWB.

Replace the engine PWB (See page 1-5-28).

Problem

Causes

Check procedures/corrective measures

Содержание ECOSYS P7035cdn

Страница 1: ...SERVICE MANUAL Published in May 2014 842PR111 2PRSM061 Rev 1 ECOSYS P7035cdn...

Страница 4: ...This page is intentionally left blank...

Страница 10: ...This page is intentionally left blank...

Страница 14: ...2PR This page is intentionally left blank...

Страница 20: ...2PR 1 1 6 This page is intentionally left blank...

Страница 28: ...2PR 1 2 8 This page is intentionally left blank...

Страница 48: ...2PR 1 3 20 This page is intentionally left blank...

Страница 154: ...2PR 2 1 20 This page is intentionally left blank...

Страница 171: ...2PR 2 3 11 2 3 3 Paper exit PWB Figure 2 3 3 Paper exit PWB silk screen diagram PH1 YC4 YC3 YC2 YC6 YC5 YC7 YC8 YC1...

Страница 177: ......

Страница 178: ......