KTR-STOP

®

YAW M B-xx

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

445120 EN

7 of 16

1

Please observe protection

note ISO 16016.

Drawn:

2019-11-18 Shg/Wie

Replacing:

---

Verified:

2019-11-22 Shg

Replaced by:

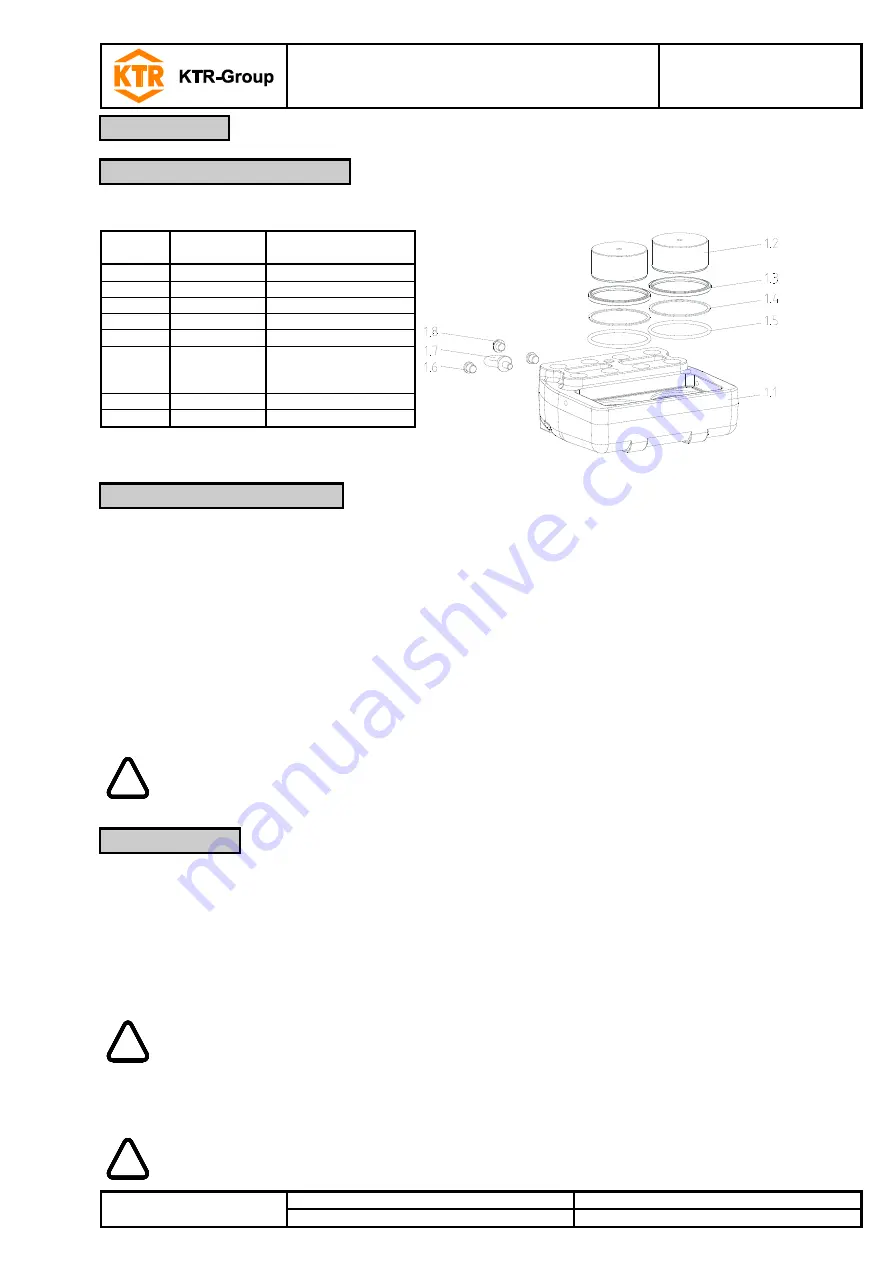

Subassembly 1 - Housing with components

Compo-

nent

Quantity

Description

Illustration

7:

Housing

with single

parts

1.1

1

Housing

1.2

2

Brake piston

1.3

2

Scraper

1.4

2

Back-up ring

1.5

2

O-ring

1.6

2

Screw plug

VSTI (acc. to

DIN 908)

1.7

1

Eye bolt DIN 580

1.8

1

Screw plug

To ensure the full braking power, the preparation for assembly needs to be performed

carefully.

•

The connection plate for the brake as well as the brake disk have to be inspected for dimensional accuracy.

For that purpose investigate the connection dimensions, connection surfaces and tolerances as specified in

the drawing (see illustrations 1 to 5 and table 2).

•

Clean and degrease the brake disk and mounting surfaces. Dirt can easily be removed by means of solvents.

The connection between connection plate and brake is defined as frictionally engaged. Any

residues of oil, dirt and corrosion protection reduce the coefficient of friction. As a result

the operation of the brake and the full braking power are no longer ensured.

!

Observe the manufacturer’s instructions regarding the use of solvents.

KTR supplies brake pads free from asbestos and lead only.

If requested, we will provide you with the respective certificates.

The brake pads are each adapted to the application and delivered accordingly.

They can be distinguished as follows:

•

organic material

•

powder metal

!

Brake pads are highly sensitive to grease and oil which means that they cannot be cleaned.

Brake pads with such dirt need to be replaced and disposed of.

We recommend to store the brake pads in their package as long as possible to protect them

from any kind of dirt.

!

Brake pads which have worn off to the wear limit have to be replaced immediately. Make

sure to replace by original parts only.

4

Assembly

4.1 Components of the brake

4.2 Preparation of assembly

4.3 Brake pads