Caution

Caution

Caution

Caution

RPH

10

5.4

Connecting the piping

Never use the pump itself as an anchorage

point for the piping. The permissible pipeline

forces must not be exceeded (see section 4.3.5).

Suction lift lines shall be laid with a rising slope towards the

pump and suction head lines with a downward slope towards

the pump. The pipelines shall be anchored in close proximity to

the pump and connected without transmitting any stresses or

strains. The nominal diameters of the pipelines shall be at least

equal to the nominal diameters of the pump nozzles. The

mating flanges must be parallel to the pump flanges.

It is recommended to install check and shut-off elements in the

system, depending on the type of plant and pump. It must be

ensured, however, that the pump can still be drained and

dismantled without problems.

Thermal expansions of the pipelines must be compensated by

appropriate measures so as not to impose any extra loads on

the pump exceeding the permissible pipeline forces and

moments.

An excessive, impermissible increase in the pipeline

forces may cause leaks on the pump where the fluid

handled can escape into the atmosphere.

Danger to life when toxic or hot fluids are handled!

The flange covers on the pump suction and discharge nozzles

must be removed prior to installation in the piping.

Please check if a strainer/filter should be fitted

in the suction line during the commissioning

stage, in order to protect both the pump and the shaft seal from

damage due to contamination from the plant.

In order to avoid any marked deterioration of the

NPSHavailable, which would have an adverse effect on the

pump, the strainer has to be cleaned whenever required. It is

recommended to use a differential pressure gauge to detect

any strainer clogging (see 6.1.6).

For installation on a foundation with vibration insulation

please take into account when connecting the piping

that the flexible elements at the baseplate may only

compensate compressive and shearing strains within the

admissible limits. Tensile strains cannot be compensated for,

therefore the flexible elements shall only be firmly fastened to

the foundation after the piping has been connected.

5.4.1

Auxiliary connections

The dimensions and locations of the auxiliary connections

(cooling, heating, barrier liquid, flushing liquid, etc.) are

indicated on the general arrangement plan or piping layout.

These connections are required for proper

functioning of the pump and are therefore of

vital importance!

Modifications are only permitted after prior consultation with the

manufacturer (see 2.7)!

5.4.2

Coupling guard

In compliance with the accident prevention regulations

the pump must not be operated without a coupling

guard. If the customer specifically requests not to include a

coupling guard in our delivery, then the operator must supply

one. In this case, it is important to make sure that the materials

selected for coupling and coupling guard are non-sparking in

the event of mechanical contact. KSB’s scope of supply meets

this requirement.

5.5

Final check

Re-check the alignment as described in section 5.3 and verify

the correct distance between the coupling and the coupling

guard.

It must be easy to rotate the shaft by hand at the coupling.

5.6

Connection to power supply

Connection to the power supply must be effected by a

trained electrician only. Check available mains voltage

against the data on the motor rating plate and select appropriate

start-up method.

We strongly recommend to use a motor protection device

(motor protection switch).

In potentially explosive atmospheres, compliance with

IEC60079-14 is an additional requirement for electrical

connection.

6

Commissioning, start-up / shutdown

Compliance with the following requirements is

of paramount importance. Damage resulting

from non-compliance shall not be covered by the scope of

warranty.

6.1

Commissioning

Before starting up the pump make sure that the following

requirements have been checked and fulfilled.

If a constant-level oiler is provided, screw same into the tapping

hole provided in the bearing bracket prior to adding the oil (see

6.1.1).

On cooled bearing brackets, fitting the constant-level oiler is

difficult due to the position of the cooling line. The connection

elbow of the constant-level oiler must be screwed in separately,

after having removed the protective cage and oil reservoir.

Afterwards, screw the oil reservoir back on and cover with the

protective cage.

The connection between bearing bracket and constant-level

oiler shall be sealed with PTFE tape, if necessary.

The operating data, the oil level, if applicable (6.1.1), and the

direction of rotation (6.1.4) must have been checked. The pump

must have been primed (6.1.3).

Also verify the following:

-

Make sure that the unit has been properly connected to the

electric power supply and is equipped with all protection

devices.

-

Make sure that all auxiliary lines (5.4.1) are connected and

functioning.

-

If the pump has been out of service for a longer period of

time, proceed in accordance with section 6.4.

On pumps delivered without a baseplate, the leakage line (part

No. 710.22) must be added as well.

6.1.1

Lubricants

Oil lubricated bearings

The bearing bracket has to be filled with lubricating oil. The oil

quality required is outlined in section 7.2.2.3 and the quantity in

section 7.2.2.4.

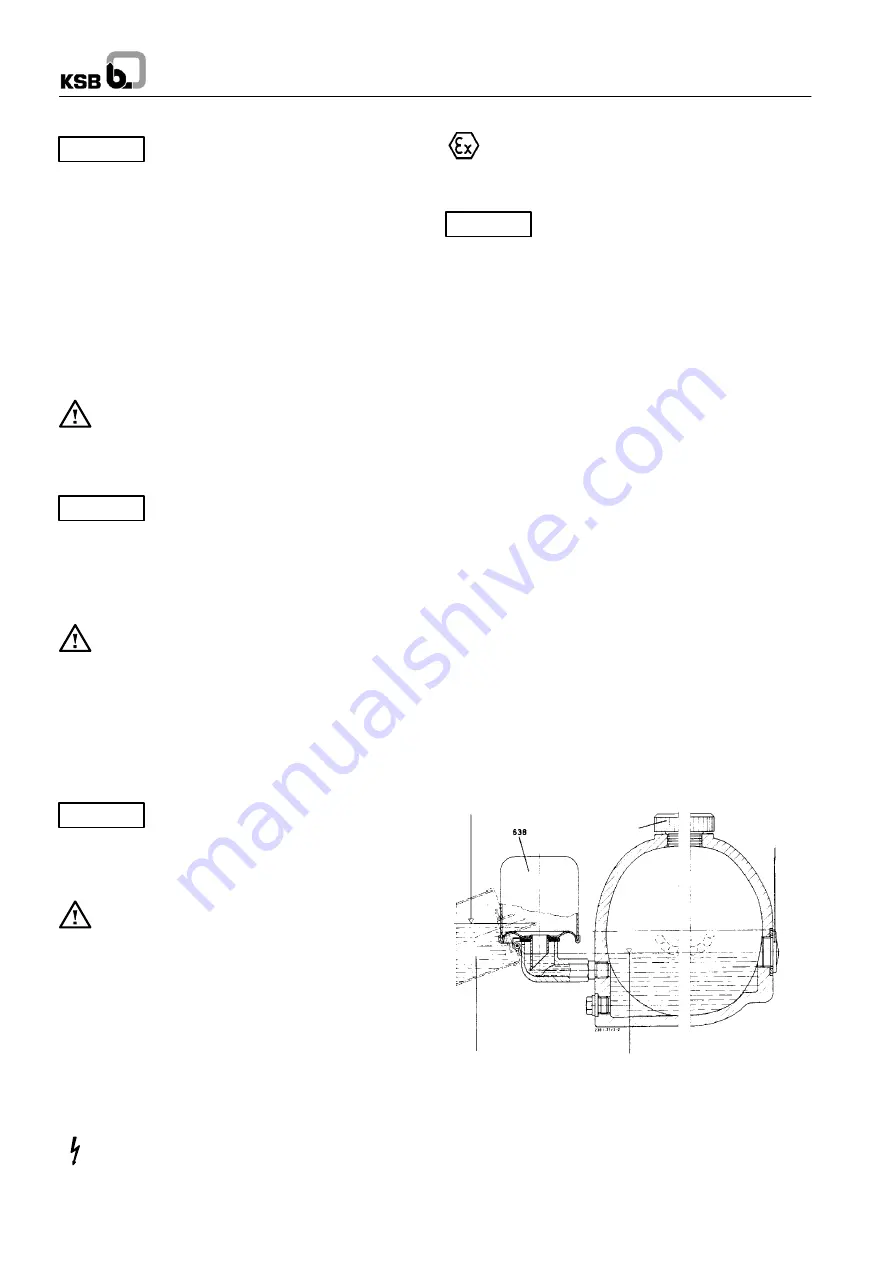

Oil level in reservoir

during filling procedure

Vent / Filler

plug

Oil level

sight glass

Position of reservoir for topping

up oil

Oil level in bearing bracket

and connection elbow

Fig. 9

Oil fill

Procedure:

Remove the protective cage of the constant-level oiler.

Unscrew vent plug. Pour in the oil through the vent plug tapping

hole after having hinged down the reservoir of the

constant-level oiler until oil appears in the vertical portion of the

connection elbow (Fig. 9).