TC · Edition 07.14

28

บริษัท เอดีดี เฟอร์เนส จ ำกัด

ADD FURNACE CO.,LTD.

44 ซอยบรมราชชนนี

70 ถนนบรมรำชชนนี แขวงศำลำธรรมสพน์ เขตทวีวัฒนำ กรุงเทพฯ 10170

โทร

: 02-888-3472

โทร

:

ออกแบ

บ

:

08-08-170-170

แฟกซ์

: 02-888-3258

https://www.add-furnace.com E-mail:

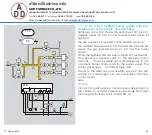

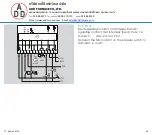

3 .3 .2 Testing after burner run: Mode 2

If the jumper is set to Mode 2, the tightness test after

burner run begins as soon as the burner is switched off.

To ensure that the valves are checked for tightness once

before starting up the system, the tightness test runs when

the voltage L1 is applied. If the valves are tight, the green

OK LED lights up. The OK enable signal is not forwarded

to the automatic burner control unit until the start-up

signal has been applied.

Once the start-

switched off, the

tightness test after burner run begins. The OK enable signal

is not forwarded to the automatic burner control unit

again until the start-

If the tightness control TC detects a leak on one of the

two valves, the red LED lights up for a fault on valve V1

1

or valve V2

2

. A fault is signalled externally , e.g.

by switching on a buzzer or a warning light.

MODE 1 2

: "

TEST

"

1 L1 (+)

5

TEST

OK

1

2

6

OK

7

tp

tp

t

V1 leaking

V2 leaking

1 L1 (+)

5

TEST

OK

1

2

6

OK

7

tp

t