TC · Edition 07.14

11

บริษัท เอดีดี เฟอร์เนส จ ำกัด

ADD FURNACE CO.,LTD.

44 ซอยบรมราชชนนี

70 ถนนบรมรำชชนนี แขวงศำลำธรรมสพน์ เขตทวีวัฒนำ กรุงเทพฯ 10170

โทร

: 02-888-3472

โทร

:

ออกแบ

บ

:

08-08-170-170

แฟกซ์

: 02-888-3258

https://www.add-furnace.com E-mail:

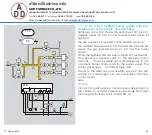

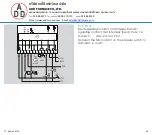

1 .1 .5 TC 2 with two gas solenoid valves and one

auxiliary valve for discharge

Tightness control TC 2 checks the gas solenoid valves V1

and V2 and the auxiliary valve V3 for tightness.

It must be ensured that the interspace is vented during the

2-second opening time. This is not guaranteed by the gas

pressure regulator downstream of V2. The test volume V

P

is

thus discharged into the combustion chamber or into a

safe area. Auxiliary valve V3 can also be used as a pilot

gas valve. Since valve V2 remains closed during the test, it

can also be a slow opening motorized valve VK.

Once the tightness test has been carried out successfully,

the tightness control forwards the OK enable signal to the

automatic burner control unit GFA. The pilot valve output

of the automatic burner control unit GFA opens the gas

solenoid valves V1 and V3 simultaneously. The main valve

output opens gas solenoid valve V2. The burner starts.

V1 and V2: quick or slow opening valves with start rate.

V3: quick or slow opening valve with start rate, nominal

size is dependent on test volume V

P

and inlet pressure

p

u

, see page 34 (Project planning information), but is at

least DN 15.

A

=

Supply

and

signal

forwarding

B

= Automatic

burner control unit

C

= Gas

solenoid valves

PZ = Internal pressure sensor of the TC for the comparison

of inlet pressure p

u

and interspace pressure p

z

TC 2

TC 2

V3

PZ

p

u

2

V1

V2

p

u

p

Z

V

P

L1(+)

N(-)

PE

OK

GFA

1 2 3

B

1 3 5 6

A

TC 2

1 2 3

C

V1 V3

V2