TC · Edition 07.14

13

บริษัท เอดีดี เฟอร์เนส จ ำกัด

ADD FURNACE CO.,LTD.

44 ซอยบรมราชชนนี

70 ถนนบรมรำชชนนี แขวงศำลำธรรมสพน์ เขตทวีวัฒนำ กรุงเทพฯ 10170

โทร

: 02-888-3472

โทร

:

ออกแบ

บ

:

08-08-170-170

แฟกซ์

: 02-888-3258

https://www.add-furnace.com E-mail:

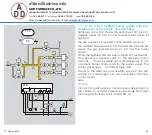

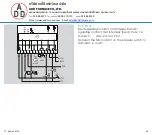

1 .1 .7 TC 2 in a multiple burner system with 3 valves

installed in series

When using slow opening main valves (V1 and V2), auxiliary

valves (V3 and V4) must be used for the supply and discharge of

the test volume V

P

.

Tightness control TC 2 checks the central shut-off valve V1, the

gas solenoid valve V2 and the auxiliary valves V3 and V4 for

tightness.

Valve V2 can only be checked for tightness when the pressure

downstream of V2 approximately corresponds to the atmos-

pheric pressure and the volume downstream of valve V2 is 5 x

V

P

. The gas solenoid valve VAS and the pressure switch DG

VAS

are used to relieve the pressure. The pressure switch must be

adjusted in such a way so that enough pressure is relieved and

no air can get into the pipework.

Once the tightness test has been carried out successfully, the

tightness control TC 2 opens the main valves V1 and V2 with the

OK enable signal and enables the downstream burner control

units.

V3 and V4: quick opening, nominal size is dependent on test

volume V

P

and inlet pressure p

u

, see page 34 (Project plan-

ning information), but is at least DN 15.

A

= Supply and signal forwarding

B

= Automatic burner control unit

C

=

Gas solenoid valves

PZ = Internal pressure sensor of the TC for the comparison

of inlet pressure p

u

and interspace pressure p

z

PZ = Pressure switch DG

VAS

for monitoring the pressure

down- stream of V2

TC 2

TC 2

PZ

p

u

2

V1

V2

p

u

p

Z

V

P

V3

L1(+)

N(-)

PE

OK

1 3 5 6

A

TC 2

1 2 3

B

V2

K1

DG

VAS

1 2 3

C

V1

K1

VAS

V3

V4

V4

V

A

S

PZ

D

G

V

A

S