TECHNICAL DATA

8

107

OPTISWIRL 4200

www.krohne.com

02/2022 - 4003930810 - MA OPTISWIRL4200 R10 en

Recommended flow velocities

Liquids

3

,

4

0.3…7 m/s / 0.98…23 ft/s (optional up to 10 m/s / 32.8 ft/s taking cavitation into account)

Gases and steam

3

2.0…80 m/s / 6.6…262.5 ft/s

DN15: 3.0…45 m/s / 9.8…148 ft/s; DN25: 2.0…70 m/s / 6.6…230 ft/s

3

These values represent the absolute limits of flow velocities. For more detailed information for your specific

application refer to

Intended use on page 7.

4

v

min

= 0.7 m/s / 2.3 ft/s in SIL mode

Other conditions

Ingress protection

Compact version:

Signal converter in aluminium housing, IP66/67

Signal converter in stainless steel housing, IP66, IP68, IP69K

Remote version:

Signal converter in aluminium housing, IP66/67; flow sensor housing, IP66/67

Signal converter in stainless steel housing, IP66, IP68, IP69K;

flow sensor housing, IP66, IP68, IP69K

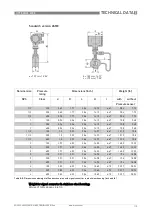

Installation conditions

Inlet section

15 DN without disturbing flow

20 DN after a pipe diameter reduction

20 DN after a single bend 90°

30 DN after a double bend 2 x 90°

40 DN after a double three-dimensional bend 2 x 90°

50 DN after a control valve

2 DN before a flow straightener;

8 DN after a flow straightener

Outlet section

5 x DN

Materials

Flow sensor and process

connections

Standard: 1.4404 / 316L

Option: Hastelloy

®

C-22 on request

Electronics housing

Aluminium die-cast, two-layer coating (epoxy/polyester)

Option: 1.4409 / 316L / A 351-CF3M

Option: die-cast aluminium with finish for advanced requirements

Pressure sensor gasket

Standard: FPM

Option: FFKM

Measuring tube gasket

(Pick-up)

Standard: 1.4435 / 316L

Option: Hastelloy

®

C-276

Selection depends on flow sensor material / medium.

Process connections

Flange version

DIN EN 1092-1

DN15...300, PN16...100 (higher pressures on request)

ASME B16.5

1/2...12", 150…600 lb (higher pressures on request)

JIS B2220

DN15...300, 10…20 K (higher pressures on request)

For detailed information on combination flange/pressure rating, refer to section "Dimensions and weights".