Type

RA-2 HV3

Operating Instructions

DOK-208-GB.doc

No. 0920-..,

0921-...

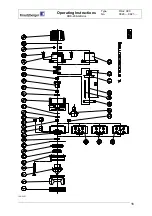

Examples for pneumatic circuitry of the automatic spray gun type RA-2 HV3

Analogue control

St

1

1

3

2

2

3/2 - G1/8

2/2 - G3/8

PDV

(e)

G1/4

PDV

(e)

G1/4

0,6 MPa

(6 bar)

O/S

(E)

O/S

F

R

Control of flat and circular jet air via

proportional pressure regulating valves

with analogue target value preset to

ensure optimum adjustment of the

spraying parameters to changing spraying

situations.

Preliminary air control is to be assured by

external control of the pressure regulating

valves.

Start of spraying: first activate spraying air

R (and, if applicable, F), then open control

air St!

End of spraying: first shut off St, then

close R and F.

PDV (e) = proportional pressure regulating

valve, electrically controlled

O/S (E) = opener/closer with vent

O/S = opener/closer

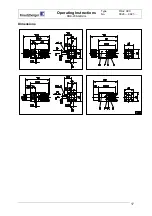

Fixed setting

St

13

2

3/2 - G1/8

F

R

1

2

2/2 - G1/4

1

2

2/2 - G1/4

0,6 MPa

(6 bar)

O/S

(E)

O/S

O/S

DV

(D)

DV

(D)

Control of flat and circular jet air via

pressure regulating valves to ensure

optimum adjustment of the spraying

parameters to a constant spraying

situation.

Preliminary air control is to be assured by

external control of the pressure regulating

valves.

Start of spraying: first activate spraying air

R (and, if applicable, F), then open control

air St!

End of spraying: first shut off St, then

close R and F.

DV (D) = pressure regulating valve,

adjusted to pressure range

O/S (E) = opener/closer with vent

O/S = opener/close

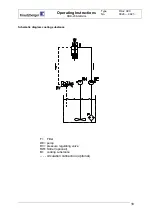

Notes

In particularly critical cases (such as the processing of substances with increased hazard

potential), it is advisable to equip the circular jet air (R) with a pressure monitor, which

should be installed directly in front of the automatic spray gun. This can prevent the

generation of a far-reaching material jet if there is insufficient air. A PE converter is

suitable for this purpose, for example.

The accessories required for this (e.g. control

valves, regulators etc.) are available from Krautzberger GmbH

12