Type

RA-2 HV3

Operating Instructions

DOK-208-GB.doc

No. 0920-..,

0921-...

If the automatic spray gun is to be dismounted when work has been completed, ensure

that no residues of toxic, flammable or explosive material or detergent remain in the

automatic spray gun (avoidance of hazard during storage or transport).

During

lengthy breaks in operation

, the automatic spray gun should be stored in a

suitable place in a cleaned condition.

Do not clean material and air nozzles using hard, sharp-edged objects!

(The following

are recommended for cleaning of the nozzles: round brush, article no. 7025120-0055 or flat

brush, article no. 7025-120-0053 from Krautzberger GmbH.)

A cloth soaked in detergent is recommended for external cleaning.

9. Disposal

Following dismantling of the automatic spray gun type RA-2 HV3, the metal parts can be

sorted and forwarded to a recycling process; the non-metal parts should be disposed of as

special waste.

10. Technical

data

Operating pressures / Operating temperature

Max. material pressure:

1.2 MPa (12 bar)

Max. material temperature:

100°C

Max. atomiser air pressure (R and F):

0.8 MPa (8 bar)

Min. control air pressure:

0.4 MPa (4 bar)

Max. control air pressure:

0.8 MPa (8 bar)

Max.

air

temperature: 50°C

Connections

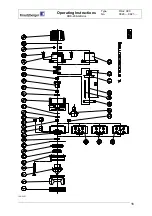

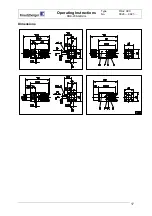

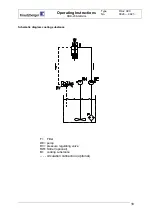

(see dimension sheet 140-0021)

Material

(M):

G1/8

IG

Atomiser air (R and F):

G1/8 IG

Control

air

(St):

PK-3/5

or

M5

IG

Weight

(without add-on parts)

approx. 500 g

Material spray zone

Angle of material jet in front of nozzle:

up to approx. 180° depending on setting

Length of material jet in front of nozzle:

depends on setting (e.g. water with a

material

pressure

of

4

bar

sprayed

through

a

1

mm

material

nozzle

hits

a

disc

measuring

2 metres in diameter at a distance of 10

metres).

Noise emission

Continuous sound pressure level:

nozzle-dependent, 73 to 96 dB(A)

Available nozzles

Material nozzles

Flat/Circular jet: stainless steel

0.3 - 2.5 mm

st. steel, hardened 0.3 - 2.5 mm

tungsten

carbide 1.2

-

2.5

mm

10