Page 20

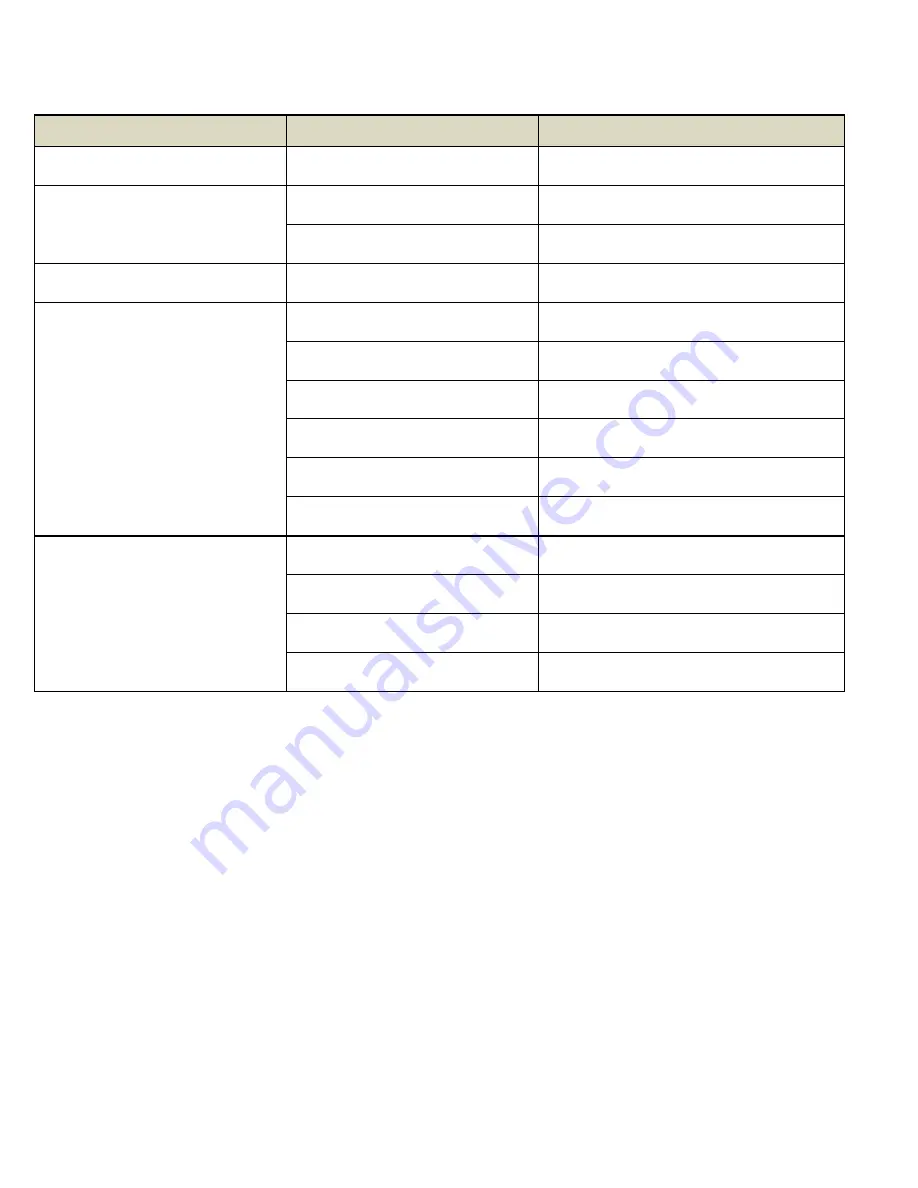

TROUBLESHOOTING

FAILURE

CAUSE

REMEDY

Burner creaks

Burner is new (wait)

Chimney is sweating

Poor insulation

Insulate the chimney well

Low exhaust temperature

Increase the minimum power / the boiler temp., it

may be necessary to restore the chimney

Pellet boiler is sweating

Check return flow increase at external control

Heating circuits do not work /

Heating system is slow to heat up

The boiler is on utility water operation

mode

Change operation mode

Hydraulic problem

Contact installer

Altered heating curve

Adjust

Heating circuit pump is defect

Fix it

Air is in the system

Bleed air from system

Pumps run on wrongrotation speed

Fix it

High temperature value on screen

No water in boiler

Fill the system

Circulation pump is not working

Activate / Fix the pump

Air in the system / boiler

Bleed air from system / from boiler

Defective boiler temperature sensor

> Inform customer service

Содержание SLIMPEL

Страница 8: ...Page 8 SPECIFICATIONS SLIMPEL 25...

Страница 9: ...Page 9 SLIMPEL 40...

Страница 10: ...Page 10 AIR ELIMINATOR VALVE BLOW OFF...

Страница 14: ...Page 14 This page intentionally left blank...

Страница 21: ...Page 21...