68

Operation of Test Print

Density Check

Check the density value according to the items to be checked shown below.

Category

Item

Number

Item to be Checked

Density

When Checking from the Message Display Window on the Operation Panel

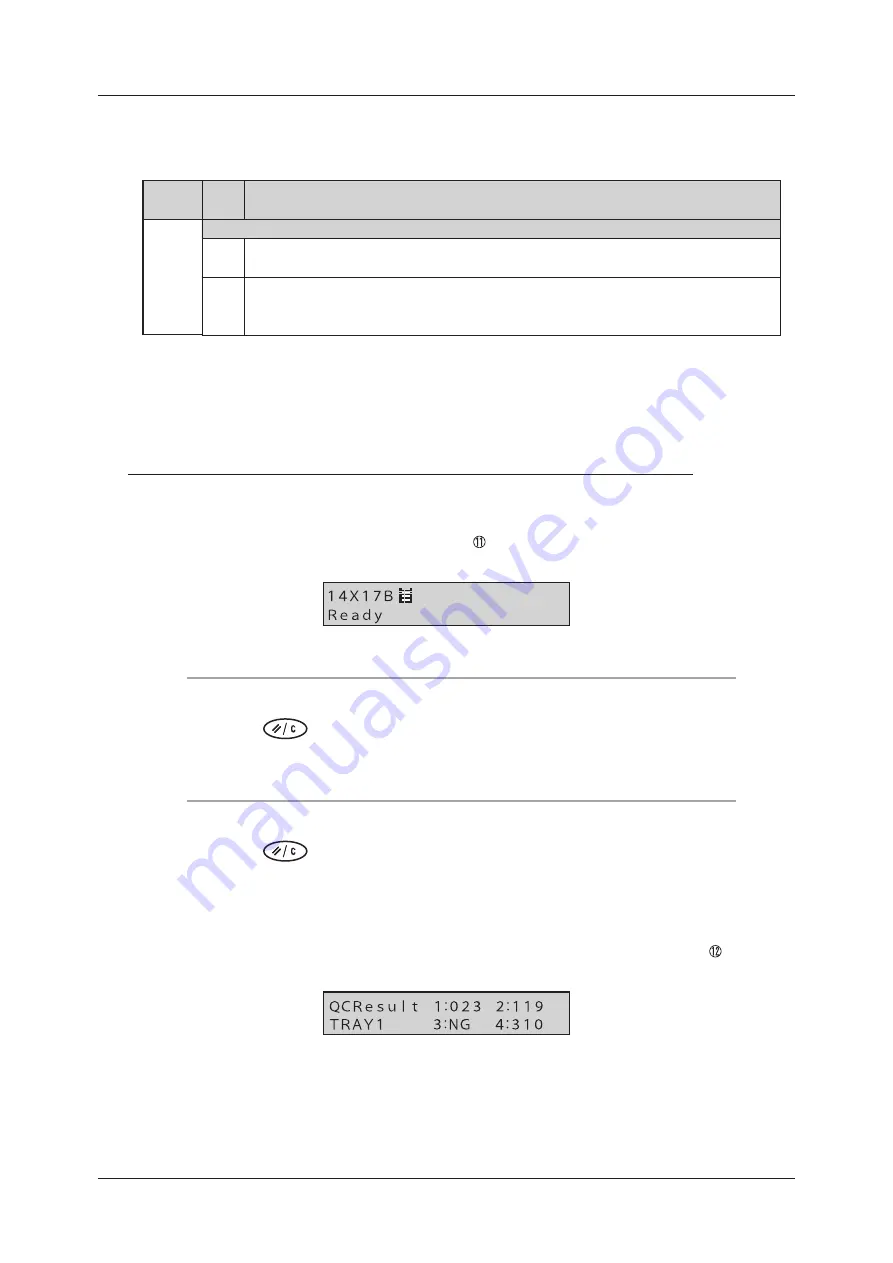

(11) After printing the QC patterns, “Dens. Error <Tray No.>” is not displayed on the DRYPRO 832

operation panel

(12) After printing the QC pattern, “NG” is not displayed in “1” to “4” of the “QC Result” in the QC

Results View on the DRYPRO 832 operation panel, but the correct density value (three digits)

is displayed

Check the readout given by the densitometer built into the main unit from the operation panel of the

main unit.

When Checking from the Message Display Window on the Operation Panel

1

Check that “Dens� Error <Tray No�>” is not displayed on the DRYPRO 832

operation panel� (Item to be checked: )

When QC patterns are printed from the standard supply tray (tray 1)

2

Press the

[Reset/Cancel] button twice�

The QC Results View of the standard supply tray (tray 1) is displayed.

When QC patterns are printed from Lispl-832 (tray2)

2

Press the

[Reset/Cancel] button three times�

The QC Results View of the Lispl-832 (tray 2) is displayed.

3

Check that “NG” is not displayed in “1” to “4” of the “QC Result” and the

correct density value (three digits) is displayed� (Item to be checked: )

After the expiration of 30 seconds without external input, the screen is restored to

the Current Status View.

Содержание Drypro 832

Страница 1: ...LASER IMAGER 01 ET EN ...

Страница 2: ......

Страница 4: ...4 Sisukord Appendix 75 A Specifications 76 B Test Print Check List 78 ...

Страница 9: ...9 Peatükk 1 Hoiatused ja ettevaatusabinõud ...

Страница 25: ...25 Chapter 2 Product Outline ...

Страница 33: ...33 Chapter 3 Operation from Main Unit ...

Страница 53: ...53 Chapter 4 Troubleshooting ...

Страница 63: ...63 Chapter 5 Maintenance ...

Страница 75: ...75 Appendix ...

Страница 80: ...80 ...

Страница 81: ...81 ...

Страница 82: ...82 ...

Страница 83: ......