19

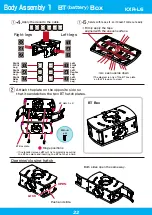

5. Select the set ID number from the ID

pull-down menu.

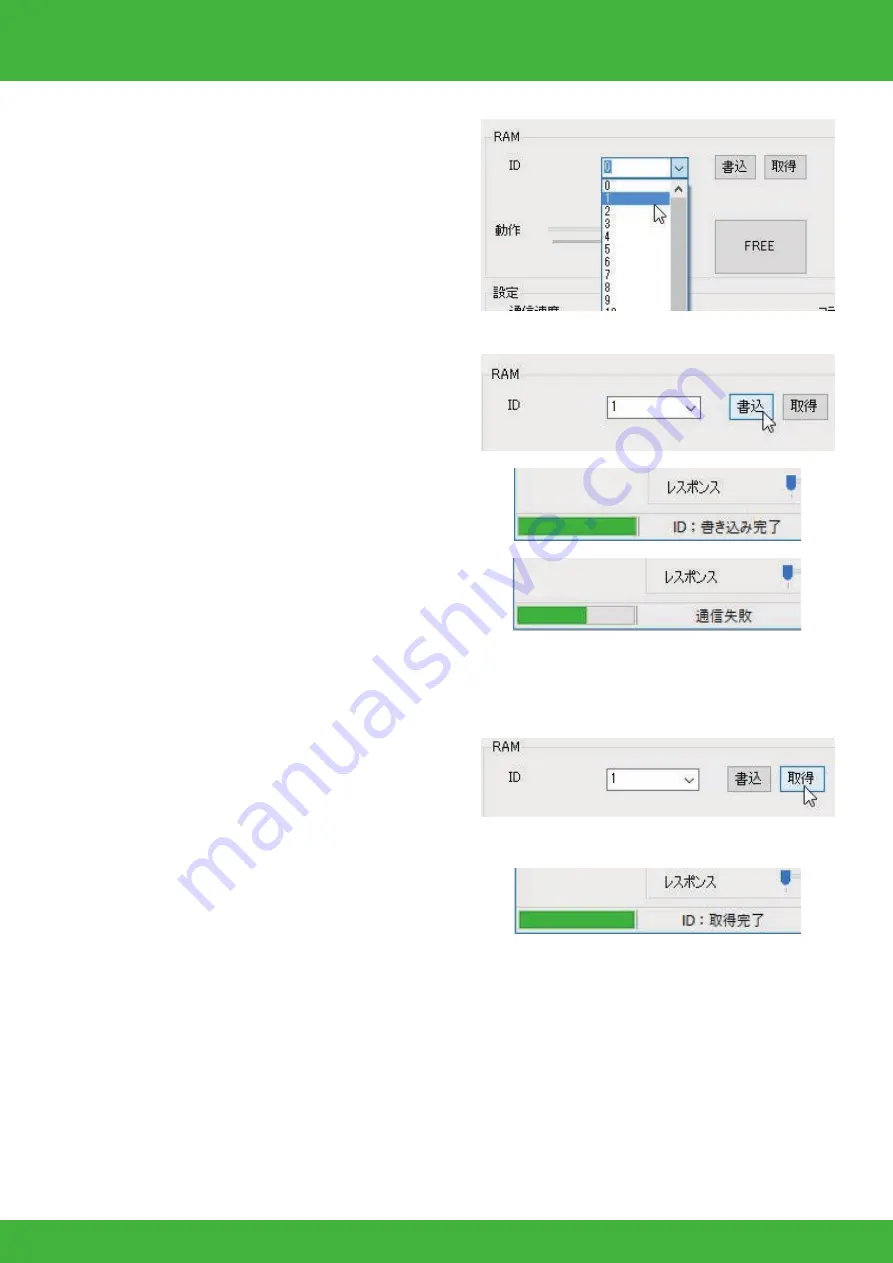

7. Just to be sure, confirm the ID. When

you press the Acquire button, the

written ID will be displayed in the

pull-down menu.

Confirm that ID: Acquire Complete is

displayed in the lower-left, and confirm

that the correct ID is displayed in the

pull-down menu.

The above is the method for changing Servo ID settings. When all of the processes

are completed, always remove the Dual USB Adaptor HS from the PC after closing the

software.

*This process is only for changing settings, so communications use the PC s bus

power, but when confirming operations, connect the battery. Refer to the manual

included with Servo Manager for information on the connection method and necessary

cable types.

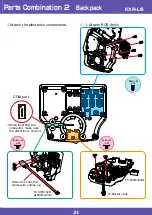

6. Press the Write button on the ID

menu and write the ID onto the servo.

If successful, ID: Write Complete will

be displayed in the lower-left box.

If it fails, Communication Failed will be

displayed, so confirm the procedures

and press the Write button again. In

particular, be sure that Dual USB Adap-

tor HS is in Serial Mode.

Setting Servo IDs 3

KXR-L6