PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

MAINTENANCE

4-16

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

4

To ensure safety at all times when operating or driving the machine, the user of the machine must always carry out

periodic maintenance. In addition, to further improve safety, the parts in the safety-critical parts list on the next

page must also be replaced at the specified interval. These parts are particularly closely connected to safety and

fire prevention, so please contact your Komatsu distributor to have them replaced.

Material quality of these parts can change as time passes and they are likely to wear out or deteriorate. However,

it is difficult to determine the extent of wear or deterioration at the time of periodic maintenance. Hence, it is

required to replace them with new ones regardless of their condition after a certain period of usage. This is impor-

tant to ensure that these parts maintain their full performance at all times.

Furthermore, should anything abnormal be found on any of these parts, replace it with a new one even if the peri-

odic replacement time for the part has not yet arrived.

If any of the hose clamps show deterioration like deformation or cracking, replace the clamps at the same time as

the hoses.

Also perform the following checks with hydraulic hoses which need to be replaced periodically. Tighten all loose

clamps and replace defective hoses, as required.

When replacing hoses, always replace O-rings, gaskets, and other such parts at the same time.

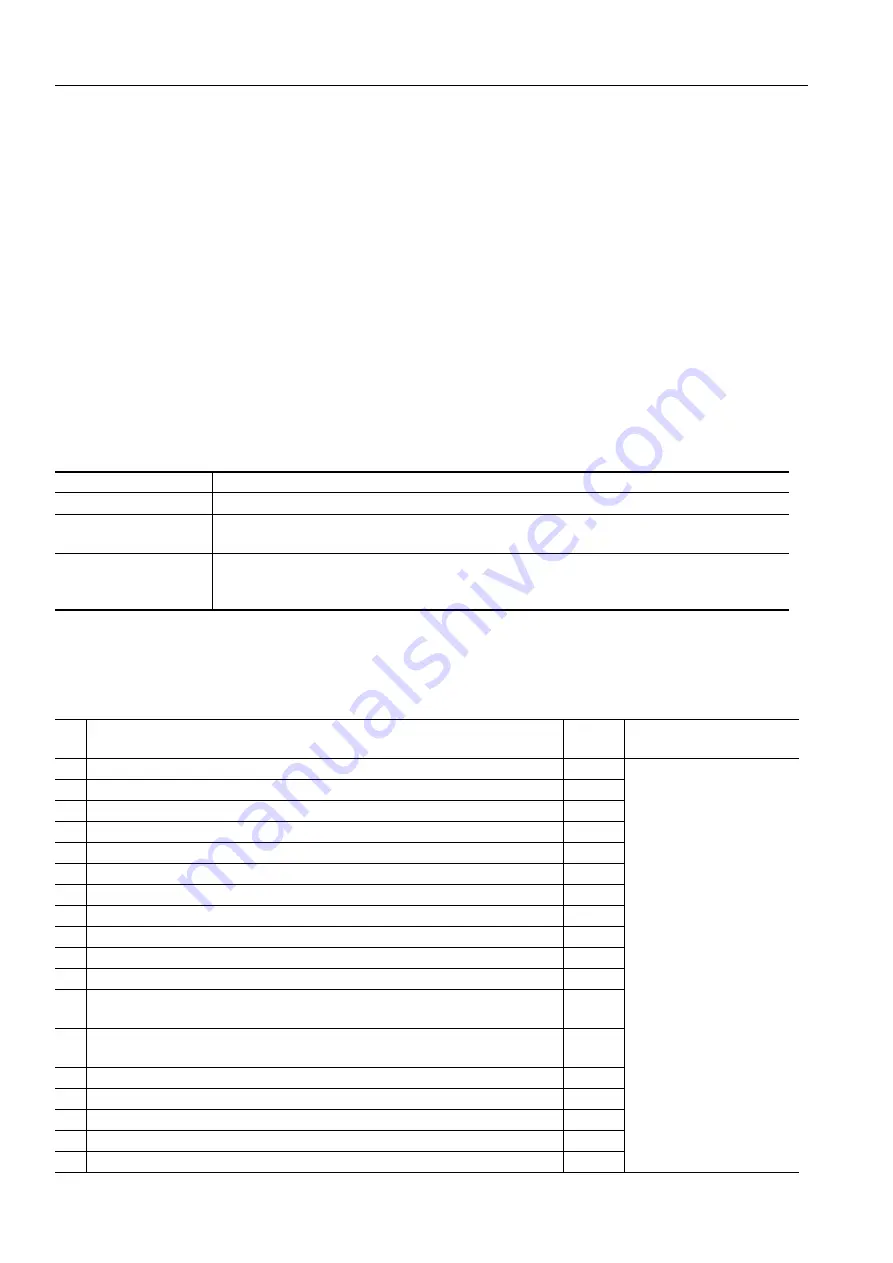

SAFETY CRITICAL PARTS

4

Interval

Check items

Check before starting Oil leakage from the connections or the clamps of fuel and hydraulic hose

Monthly inspection

Oil leakage from the connections or the clamps of fuel and hydraulic hose.

Damage (crack, wear and tear) of fuel and hydraulic hose.

Yearly inspection

Oil leakage from the connections or the clamps of fuel and hydraulic hose.

Interference, deformation, deterioration and damage (crack, wear and tear) of fuel and

hydraulic hose.

NO

.

Safety critical parts for periodic replacement

Q'ty

Replacement interval

1

Fuel tank

-

hand priming pump

1

Every 2 years or

4000 hours,

whichever

comes sooner

2

Engine overflow nipple

-

joint (bottom of fuel tank)

1

3

Engine overflow nipple

-

joint (bottom of fuel tank)

1

4

joint (bottom of fuel tank)

-

fuel tank (overflow)

1

5

joint (bottom of fuel tank)

-

fuel tank (spill)

1

6

Hand priming pump

-

supply pump

1

7

Power train pump

-

Power train filter

1

8

Steering case cover

-

HSS motor gear train

1

9

Power train filter

-

transmission control valve

1

10 Transmission control valve

-

brake valve

1

11 Torque converter

-

oil cooler

1

12 Oil cooler

-

transmission case,

torque converter case

1

13

Central pressure detection

hose

-

transmission case,

torque converter case

1

14 Hydraulic tank

-

charge pump

1

15 Charge pump

-

charge filter

1

16 HSS, PPC charge valve

-

accumulator

1

17 HSS, PPC charge valve

-

hydraulic tank

1

18 HSS, PPC charge valve

-

PPC lock valve

1

Содержание 76243

Страница 2: ......

Страница 3: ...FOREWORD 11 ...

Страница 5: ...FOREWORD FOREWORD 1 3 q Machine equipped without cab Back pocket of operator s seat ...

Страница 16: ...NECESSARY INFORMATION FOREWORD 1 14 ...

Страница 17: ...FOREWORD NECESSARY INFORMATION 1 15 ...

Страница 24: ...CONTENTS 1 22 ...

Страница 28: ...SAFETY LABELS SAFETY 2 4 SAFETY LABELS 2 POSITIONS OF SAFETY PICTOGRAMS 2 ...

Страница 211: ...MAINTENANCE 14 WARNING Please read and make sure that you understand the safety volume before reading this section ...

Страница 289: ...SPECIFICATIONS 15 ...

Страница 294: ...HEADREST HANDLING ATTACHMENTS OPTIONS 6 4 HEADREST HANDLING 6 Use the headrest fully pushed in to the lowest position ...

Страница 297: ...INDEX 17 ...

Страница 298: ...INDEX 7 2 ...

Страница 301: ...COLOPHON 18 ...

Страница 302: ...COLOPHON 8 2 D155AX 5 GALEO BULLDOZER Form No EEAM023402 2005 KOMATSU All Rights Reserved Printed in Belgium 09 05 ...