Page 25

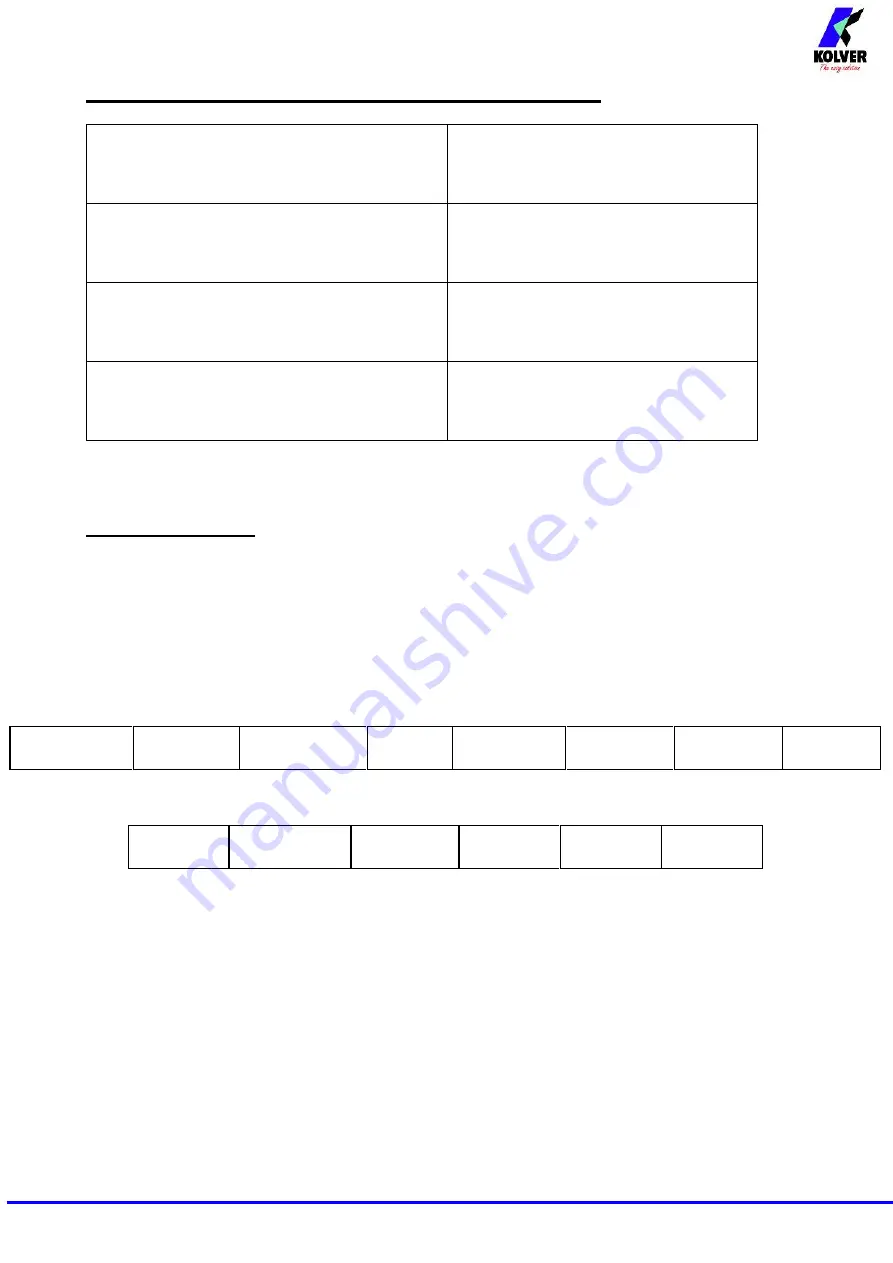

CORRECT SCREWS MESSAGES ON DISPLAY

On the status bar it will display

“Screw OK”.

A correct screwing has been performed,

reaching the pre-set torque value.

On the status bar it will

display “

Angle OK

”.

A correct screwing has been performed,

reaching the pre-set angle.

On the status bar it will

display “

Runtime OK

”.

A correct screwing has been performed,

reaching the pre-set runtime.

On the status bar it will display

“

Reverse torque

OK”

A correct screwing has been performed,

reaching the pre-set reverse torque

value.

SERIAL PRINT:

Every control unit is supplied with a 9 pin serial female connector (connection pin: PIN 2 = TX, PIN 3 =

RX, PIN 5 = GND) and a mini USB connector. You can print the results of each screwing on PC (for

example through Hyper Terminal or EDU EXPAND programs) and/or a printer (for example Kolver model

PRNTR1). You can also save those results on a USB device (only on EDU2AE/TOP/NATO/E and

EDU2AE/TOP/NATO/TA). The transmission characteristics (only serial and USB) are the following: 9600

(bits per second), 8 (data bits), n (no parity), 1 (bits stop 1).

The print string is the following:

SCREW

SEQUENCE

STAGE

TORQUE

ANGLE

DATE

HOUR

NOTICE

BC: Barcode =

it begins with “BC:” and it’s followed by the code of the scanned product.

Result = screwing result: correct or incorrect.

OK = the torque has been correctly reached, all the selected parameters are satisfied and the control

unit will give out a beep sound of 0.5 sec.

NOK = the torque has been reached during ramp time or brake time (see error table). In this

case, the unit will give out 2 beepsounds and the red led will light up.

PR: Program number = it indicates the running program.

Model =

Model of screwdriver you’re using

.

T%: Torque% = percentage of the set torque level.

S: Speed = preset speed value.

ST: Screwing time = it indicates the time of the screwing.

J: Joint = type of preset joint (H= hard o S=soft).

BARCODE

RESULT

PROGRAM

NUMBER

MODEL

TORQUE%

SCREWING

TIME

SPEED

JOINT

Содержание EDU 2AE/TOP/NT

Страница 17: ...Page 17 I O CONNECTIONS...