26

1493936-W2-A

Servicing

Warning! There are no user serviceable parts inside the shower. Servicing

of the shower must only be carried out by qualified, competent personnel

following the instructions provided in this guide and those provided with

any spare part. Before replacing any parts, ensure that the underlying cause

of the malfunction has been resolved.

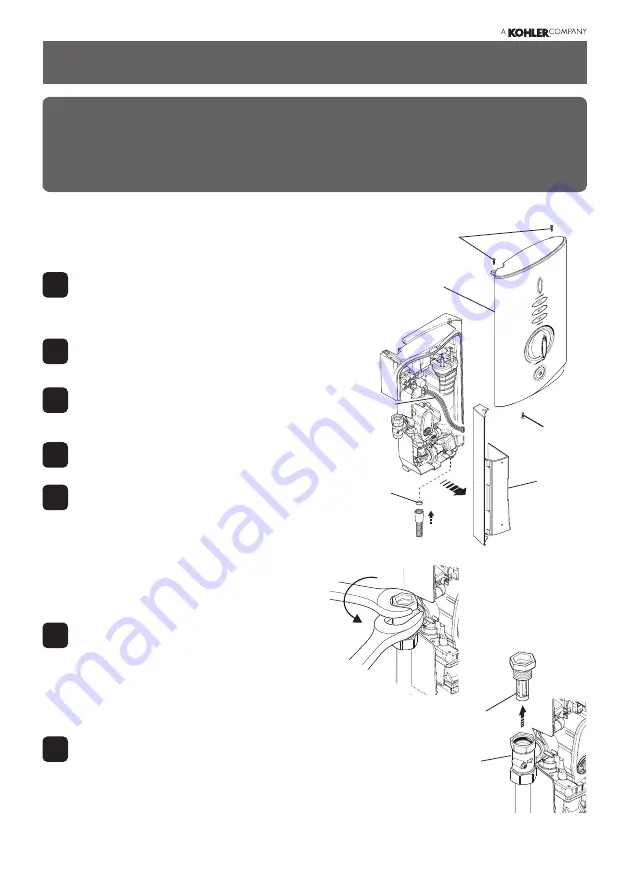

Inlet Connector

Assembly

Inlet Filter

Screws

Service

Tunnel

Screw

Cover

Cleaning the Inlet Filter

Warning!

Isolate the electrical and water

supplies before removing the cover.

1

3

4

2

5

6

7

Remove the shower hose.

Note:

Retain the Hose Washer

for further use

Remove the three cover retaining

screws and remove the cover.

Unplug

the multi-connector and

place the cover to one side.

Remove the service tunnel.

Use a suitable spanner to remove

the filter from the inlet connector

assembly. Hold a wrench across

the flats of the inlet connector

assembly to prevent damage to

the connector, whilst removing

the filter.

Remove the filter and rinse under

a running tap to remove any

lodged particles. If necessary, use

a kettle descalent in accordance

w i t h t h e m a n u f a c t u r e r ’s

instructions.

Refit the components in reverse

order.

Note:

The multi-connector

will only locate correctly into the

cover socket in one direction.

Hose

Washer

Multi-

Connector