22.6

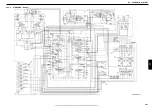

BUCKET CIRCUIT

This section describes the following.

(1) Bucket digging pilot circuit

(2) Auto accel operation

(3) Flow control in the work mode

(4) Bucket digging travel straight main circuit

(5) Bucket spool stroke limiter

22.6.1

PILOT CIRCUIT FOR BUCKET

DIGGING

(1) Mechatronics:

1.

When the operation for bucket digging is

performed, the pilot proportional secondary

pressure is delivered through port 1 of the right

pilot V (9), flows to PAc port, and acts on the

low pressure sensor (SE-1), and at the same time

the bucket spool is switched.

2.

The voltage output by low pressure sensor

inputs in mechatro controller. The mechatro

controller performs signal processing and outputs

current corresponding to the increase of pump

flow rate to pump proportional valves (PSV-P1)

and (PSV-P2) on the P1 and P2 pump sides, and

at the same time the command current is output

to P1 unloading valve (PSV-D), P2 unloading

valve (PSV-B) and travel straight proportional

valve (PSV-C).

In the following pages, the relation of operation of

low pressure sensor to both the increase of pump

flow rate and unloading proportional valve is the

same. Therefore the explanation is omitted.

3.

The secondary pressure output by P1 pump

proportional valve (PSV-P1) and P2 pump

proportional valve (PSV-P2) exerts on pump

regulator, actuating the pump onto the delivery

flow increase side.

4.

The secondary pressure delivered in P1 unloading

valve (PSV-D) and P2 unloading valve (PSV-B)

is led to PCb and PCa ports provided in control

valve (2).

The secondary pressure from proportional valve

which has exerted on PCb and PCa ports

switches the unloading spool in CLOSE side.

5.

The secondary pressure delivered in travel straight

proportional valve (PSV-C) is led to PTb port

provided in control valve (2) and shifts the travel

straight valve.

22.6.2

AUTO ACCELERATION OPERATION

(1) Principle:

Auto acceleration actuates according to signals

from low pressure sensor.

(2) Operation:

<When lever is set to neutral position>

In the event where the sensor does not receive

signal for 4 seconds or more even though the

acceleration dial is set to MAX position, the

engine speed should be raised to 1000 rpm.

<When lever is operated>

When the pressure 0.6 MPa (87 psi) is input to

low pressure sensor in STD specification (travel,

bucket, swing, arm), proportional voltage from

low pressure sensor inputs in mechatro

controller, and then the engine speed returns to

the dial set position corresponding to the lever

operation.

22.6.3

STAND-BY CURRENT CONSTANT

CONTROL

(1) Principle:

When the engine speed is intermediate speed or

lower, command current value to have the pump

delivery rate constant is output.

(2) Operation:

Even if the engine speed specified by acceleration

potentiometer is low speed, as the delivery rate

corresponds to the intermediate speed, the

actuator moves earlier than the movement

equivalent to the control lever angle rate in light

load operation.

22.6.4

BUCKET DIGGING AND TRAVEL

STRAIGHT CONFLUENCE (CONFLUX)

MAIN CIRCUIT

(1) Operation:

1.

The oil delivered through A1 port of P1 pump

goes into P1 port of C/V (2), opens load check

valve LCc through parallel circuit and enters in

bucket spool.

2.

On the other hand, the oil delivered through P2

port of P2 pump goes into P2 port of C/V (2),

confluences with oil from P1 pump through travel

straight valve, and goes into bucket spool.

(Confluence of oil from 2 pumps)

3.

With the function of pilot circuit, the oil flow is

switched from bucket spool, and is fed into

bucket cylinder head side through AC port of

C/V (2). On the other hand, the return oil from

cylinder rod (R) side is throttled by bucket spool

and returns to tank circuit from BC port of C/V

(2).

References:

・

In bucket dumping operation, the travel straight

valve also switches like digging operation,

resulting in confluence with travel straight.

・

When the bucket operation and other operation

are simultaneously performed, the travel straight

valve does not actuate, resulting in single flow of

bucket circuit.

22.6.5

BUCKET SPOOL STROKE LIMITER

(1) Purpose:

To secure simultaneous operability of boom and

arm and to prevent cavitations at low engine

speed.

(2) Operation:

On boosting up attachment pressure, pilot

primary pressure exerts on PCc port of C/V(2)

through attachment booster solenoid valve,

operates stroke limiter of bucket spool, and

throttle oil path of spool. As a result, P1 pump

pressure increases, making the simultaneous

operation of boom up and bucket digging possible.

Even though the engine speed is low, similarly

the cavitations can be prevented by actuating the

stroke limiter.

[

22. HYDRAULIC SYSTEM

]

22-12

Copyright © 2015 Kobelco Construction Machinery Co.,Ltd. All rights reserved. [S5YN0046E03] [0109CsCshWbYs]