KNIGHT SMART CART OPERATION MANUAL

SECTION 4

MAINTENANCE

16

4.4.2 Periodic Inspection (Documented)

This is a thorough examination of the cart and its chains conducted by a qualified person, making

records of external conditions to provide a basis for the cart’s continuing evaluation. This

Inspection should be carried out at the following intervals:

A. Light Service

or

Service Class 0/1

–

Yearly

(equipment remains in place).

B. Moderate Service

or

Service Class 2

–

Every Six Months

(equipment remains in place unless external conditions indicate that disassembly

should be done to permit detailed inspection).

C. Heavy Service

or

Service Class 3

–

Every Three Months

(equipment remains in place unless external conditions indicate the disassembly

should be done to permit detailed inspection).

D. Very Heavy Service

or

Service Class 4

–

Every Six Weeks

(equipment remains in place unless external conditions indicate that disassembly

should be done to permit detailed inspection).

4.4.2.1 Recommendations for Periodic Inspections

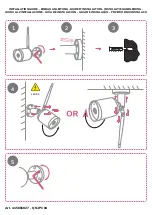

Perform the inspection detailed under section 4.4.1.1 “What to Look for During a

Frequent Inspection” of this manual.

Next, the chains should be cleaned for inspection, using any cleaning method that will not

cause damage. Adequate lighting should be provided for the person inspecting the

chain. The chain should be examined link by link for cracks, gouges, nicks, distortion,

corrosion, deposits of foreign material, and for interlink wear. To inspect for wear at the

interlink contact points, slacken the chain and rotate adjacent links to expose the inner

surface of the link. If wear is observed or if elongation is suspected, measure the chain

using a chain gauge for the Smart Cart.

A. Chain Link Thickness

If chain is worn to less than the minimum allowable thickness (T), remove the

chain from service. (Refer to Figure 4-1)

Minimum Allowable Chain Link Thickness at Any Point

Nominal Chain Size

Minimum Thickness “T”

Inches

mm

Inches

mm

.157

4.0

.137

3.48

.196

5.0

.171

4.35

Figure 4-1

T