5 Maintenance

■

Check and filling of hydraulic oil

1. Park the vehicle at ground level and make sure

the shovel contact with ground.

2. Check hydraulic oil level to see if it reaches

regulated quantity.

3. It means normal if liquid level is between

indicated scope of oil gauge.

4. In case of insufficient oil, fill in oil from filling

opening.

leakage. Use brake fluid equivalent to hydraulic

working oil ISO VG 32. General plant brake fluid

is strictly forbidden. The oil level must be between

upper and lower limits.

Spraying washing box for windfi9elds Brake

fluid cup

■

Check of cleaning agent in windshield

washer

Using windshield washer with empity tank may

destroy electric machine. So fill in cleaning agent

in advance.

■

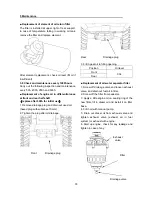

Grease filling position at working machine

of shovel

Apply grease on each oil cup with arrow.

1. Pin at installation position of moving arm

(

2 points

)

2. Pin at installation position of shovel

(

2 points

)

Liquid level

and oil

temperature

gauge

Use the hydraulic oil regulated on appendix.

Important

* Remove all sands and wastes around and use

hydraulic oil with same brand name.

* Do not open filling opening immediately after

shut down of engine. The sprayed hot oil is rather

dangerous.

■

Check and fill of fuel

1. Check oil level with fuel gauge.

2. In case of insufficient fuel, unlock outer shield

and fill in the fuel and then close the shield.

Supplementary

* Fill in oil after working to avoid dew mixing into

moisture.

■

Check and filling of oil level in brake fluid

cup

Check oil level of brake fluid. In case of rapid

reduction of brake fluid, please check for any

3. Connecting pin of push-pull rod

(

1 point

)

4. Rocker pin

(

3 points

)

5. Pin at bottom of dumper cylinder

(

1 point

)

6. Connecting rod pin of moving arm cylinder

(

2 points

)

7. Pin at bottom of moving arm cylinder

(

2 points

)

26

Содержание KDD03

Страница 2: ......