ADJUSTMENTS & OPERATION

Blade Selection

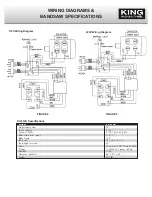

This bandsaw is equipped with a saw blade that is adequate for a variety of jobs on a variety of common materials. Refer to Fig. 8 below for

the speeds recommended for various materials. These speeds, while appropriate for many common cutting needs, do not encompass the

wide variety of special blade configurations (tooth pitch and set) and special alloys for cutting unusual or exotic materials.

A coarse blade could be used for a solid steel bar, but a finer tooth blade would be used on a thin-wall steel tube. In general, the blade choice

is determined by the thickness of the material; the thinner the materials, the finer the tooth pitch. A minimum of three teeth should be on the

work piece at all times for proper cutting. The blade and workpiece can be damaged if the teeth are so far apart that they straddle the work

piece.

For very high production cutting of special materials, or to hard-to-cut materials such as stainless steel, tool steel or titanium, you can ask

your industrial distributor for more specific blade recommendations. The supplier that provides the workpiece material should be able to

provide you with very specific instructions regarding the best blade (and coolant or cutting fluid, if needed) for the material or shape supplied.

Blade Removal and Installation

Warning!

Use leather gloves when changing the saw blade to protect

your hands from cuts and scratches. Use protective eye wear that

meets ANSI specifications.

Warning! Disconnect the bandsaw from its electrical power

source.

1) To remove the blade, place the saw frame in the rearmost position

by pushing down on the saw frame release lever (H-Fig.6) and lock

it by turning the hydraulic feed stop dial (E-Fig.6) clockwise.

2) Remove the cabinet side panel (diagram# 173) to expose the lower

blade wheel.

3) Open the upper wheel cover (diagram# 124) to expose the upper

blade wheel.

4) Remove the blade safety guard (diagram# 41) .

5) Turn the blade tension handle (A-Fig.6) counterclockwise until the

blade hangs loose.

6) Use leather gloves to prevent cuts and scratches. Pull the blade off

the drive wheels and out of the blade guides. Store the removed

blade carefully before proceeding.

7) To install the blade, slide the new blade into the blade guides.

8) Place the blade over the bottom wheel.

9) Place the blade over the top wheel. The teeth must point down

toward the table.

10) Push the blade so it is seated against the shoulders of the wheels.

11) Turn the blade tension handle clockwise enough to hold the blade

firmly in place.

12) Reconnect the saw to its electrical power source.

13) Turn the machine on to allow the blade to position itself. Check and

adjust the tracking of the blade. Refer to Blade Tracking

Adjustments in this manual.

14) Turn the blade tension handle clockwise to finish tightening the

blade. Do not over-tighten the blade; tighten it just enough so it

does not slip while cutting.

15) Reinstall the wheel guards and blade covers.

The most common causes of your bandsaw not cutting straight are:

1) Blade tension is set too low.

2) The blade is either dull or worn on one side. Blade teeth may have

lost their set.

3) The blade is upside down. The teeth must point down toward the

table.

FIGURE 8