MAINTENANCE, ADJUSTMENTS

& TROUBLESHOOTING

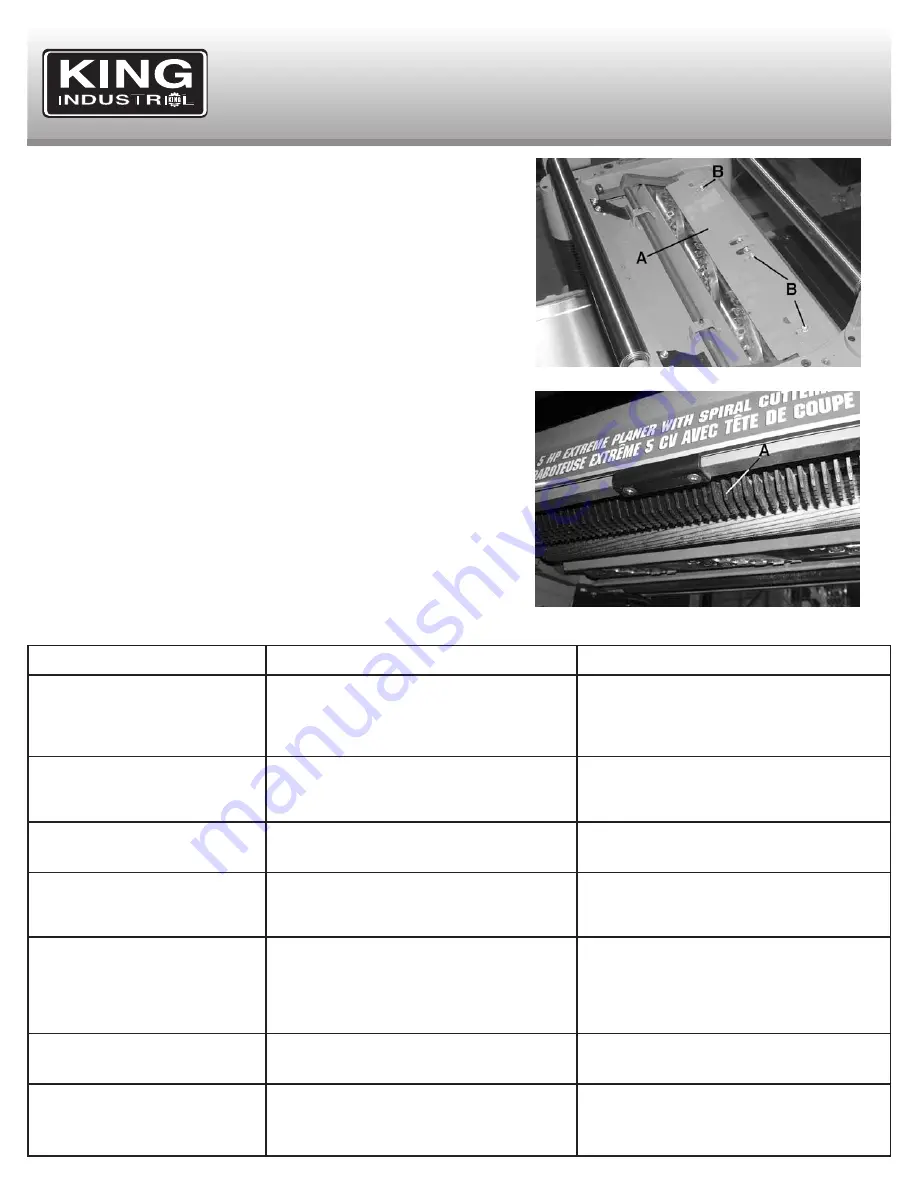

ADJUSTING CHIP DEFLECTOR POSITION

The chip deflector (A) Fig.23 prevents chips from getting onto the outfeed

roller. To adjust the chip deflector position;

1) Disconnect the planer from the power source.

2) Remove the dust hood and top cover.

3) Loosen the 3 chip deflector flange hd hex. bolts (B) Fig.23.

4) If you use a dust collection system, position the chip deflector edge 1/4”

from the closest carbide cutter insert in the cutterhead.

5) If you do not use a dust collection system, position the chip deflector

edge 1/16” from the closest carbide cutter insert in the cutterhead.

6) Once the adjustment is done, retighten the chip deflector flange hd hex.

bolts.

CLEANING ANTI-KICKBACK FINGERS

This planer comes with an anti-kickback safety system, the anti-kickback

fingers (A) Fig. 24 should be inspected regularly for resin build-up and saw

dust accumulation. If the anti-kickback fingers do not swing freely, clean

them with a wood resin solvent.

Do not apply oil or lubricants to the anti-kickback fingers. These products

attract dust and dirt and will restrict the movement of the anti-kickback

fingers.

FIGURE 23

FIGURE 24

Problem

Motor will not start

Motor overheats.

Cutting slows or squeals when

cutting.

Vibration when running or cutting.

Excessive snipe (uneven gouge in

the end of the board).

Long lines or ridges that run along

the length of the board.

Gloosy finish.

Probable cause

1) Low voltage.

2) Open circuit in motor or loose connection.

3) Emergency stop button is depressed.

1) Motor overheated.

2) Air circulation through the motor is restricted.

1) V-belts are loose.

2) V-belt are worn out.

1) Loose or damaged cutter insert.

2) Damaged v-belt(s).

3) Worn cutterhead ball bearings.

1) One or both table rollers are adjusted too high.

2) Outfeed extension table slopes downwards

and is not level with table.

3) Chipbreaker or pressure plates are adjusted

too low.

1) Nicked or chipped cutter insert(s).

1) Cutter inserts are dull.

2) Feed rate is too slow.

3) Cutting depth is too shallow.

Probable solution

1) Check power line for proper voltage.

2) Check all lead connections on the motor.

3) Rotate stop button counterclockwise until it

pops out or replace it.

1) Reduce cutting load, make lighter passes.

2) Clean motor vent openings to increase air

circulation.

1) Tighten V-belts.

2) Replace V-belts.

1) Tighten, rotate or replace cutter insert.

2) Replace with new v-belts.

3) Check or replace cutterhead ball bearings.

1) Lower the bed rollers.

2) Level outfeed extension table.

3) Raise the height of the chipbreaker or

pressure bars.

1) Rotate or replace cutter insert(s).

1) Rotate or replace cutter insert(s).

2) Increase the feed rate.

3) Increase the depth of cut.